Have you ever wondered how much your woodworking projects should cost? People often get stuck on pricing. It can feel tricky to know what to charge for your hard work.

Imagine you’ve just built a beautiful bookshelf. You’re proud, but what should you ask for it? Should it be $50? Or maybe $200? The right price can make a big difference.

In this woodworking pricing guide, we will help you figure out the best way to price your creations. We’ll look at costs, materials, and time. You’ll learn how to be fair to yourself and to your customers.

Here’s a fun fact: Did you know that some wooden toys sell for over $100? People love quality craftsmanship. They appreciate unique pieces that tell a story.

If you’re looking to sell your woodworking projects or just want to understand pricing better, this guide is for you. Let’s dive in and make sense of woodworking prices together!

Table of Contents

Comprehensive Woodworking Pricing Guide: Maximize Your Craft

Understanding woodworking pricing helps you plan your projects better. This guide breaks down costs for materials, tools, and labor. Have you ever wondered why some furniture is expensive while others are cheaper? It often comes down to quality and craftsmanship. By knowing the average prices, you can budget wisely and make informed choices. Keep in mind, every project is unique, and asking for quotes can lead to surprising savings. Start exploring woodworking today!

Understanding Woodworking Costs

Breakdown of common expenses in woodworking projects. Factors influencing pricing in woodworking.

Woodworking can be a fun adventure, but it does come with costs. First, let’s break down the expenses. You’ll need materials like wood, tools, and even safety gear. You might think a hammer is cheap, but those fancy tools can make your wallet feel lighter!

Many things affect pricing: wood type, project size, and your skill level. Hardwood costs more than softwood, and large projects might need extra supplies. So, whether you’re crafting a birdhouse or a dining table, plan your budget wisely. Remember, the only thing more expensive than high-quality tools is fixing a mistake!

| Expense Type | Cost Range |

|---|---|

| Wood | $2 – $15 per board foot |

| Tools | $20 – $500+ |

| Finishes | $10 – $50 |

| Safety Gear | $15 – $100 |

Labor Costs in Woodworking Projects

Analyzing the cost of professional vs. DIY woodworking. Regional variations in woodworking labor prices.

Considering the costs in woodworking, labor can make a big difference. Hiring a professional is often more expensive, but they come with expertise. DIY enthusiasts can save money by taking on projects themselves, but they might need extra time and effort. Also, labor prices vary by region. For example, big cities usually have higher rates than small towns. Here’s a fun look at some costs.

| Region | Average Labor Cost per Hour |

|---|---|

| East Coast | $50 |

| Midwest | $35 |

| West Coast | $60 |

| Small Towns | $25 |

So, whether you hire a pro or get your hands dirty, woodworking can be a fun adventure! Just remember, every hour counts!

Tools and Equipment Expenses

Essential tools for woodworking and their investment costs. Longterm vs. shortterm equipment costs.

In woodworking, having the right tools is key. Basic items like saws, drills, and sanders can cost anywhere from $50 to $500 each! Spending money on good tools is worth it since they last longer and make your projects easier. Short-term tools might save cash now, but you’ll find yourself replacing them often. Here’s a simple cost breakdown:

| Tool | Cost Estimate ($) | Long-term Benefit |

|---|---|---|

| Saw | 50 – 300 | Lasts for years |

| Drill | 30 – 200 | Easy to use |

| Sander | 40 – 250 | Makes smooth surfaces |

Think of your tools as your best buddies in woodworking. Choose wisely so they can help you build amazing things!

Estimating Pricing for Specific Woodworking Projects

Common woodworking projects and average costs associated. Factors to consider when estimating project costs.

Knowing how much a woodworking project will cost can save your wallet a lot of pain! Common projects like birdhouses or coffee tables range in price from $30 to $500. Factors to think about include material choice, tools needed, and your own skill level. Remember, the more complicated the project, the higher the cost. Here’s a quick overview:

| Project | Average Price |

|---|---|

| Birdhouse | $30 – $50 |

| Coffee Table | $150 – $500 |

| Bookshelf | $100 – $400 |

So, make a list, grab your tools, and get ready for some fun! Remember, even the most experienced woodworkers started with a whittle and a giggle.

Pricing Strategies for Woodworkers

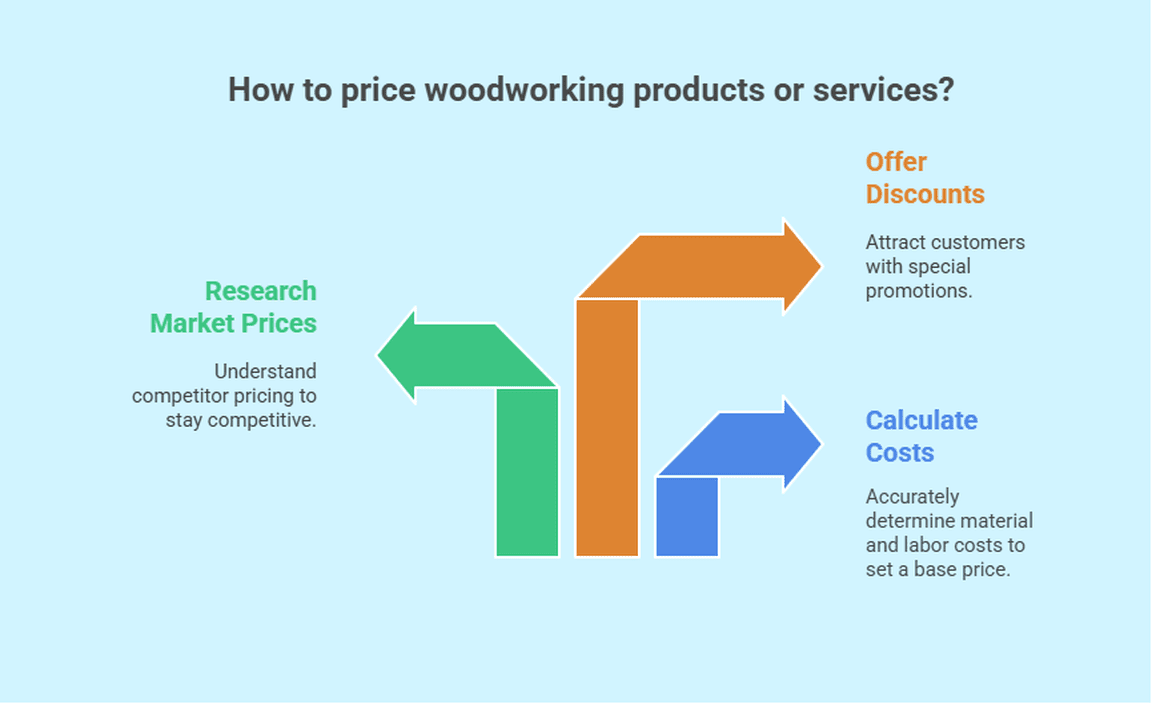

How to effectively price your woodworking products or services. Tips for competitive pricing in the woodworking market.

Setting the right price for your woodworking creations can feel tricky. Start by knowing your costs. Add up the price of materials, tools, and your time. It’s like baking a cake—you need the right ingredients! For a competitive edge, check what others charge for similar items. You don’t want to be the priciest “tree in the forest,” right? Consider special offers or discounts to attract customers. Remember, a fair price means happy customers—and happy customers tell their friends!

| Factor | Tips |

|---|---|

| Materials | Calculate total costs accurately. |

| Labor | Don’t underestimate your skill! |

| Market Prices | Research local competitors. |

| Discounts | Offer seasonal promotions. |

Marketing Your Woodworking Services at the Right Price

Strategies for attracting clients with competitive pricing. Balancing quality and affordability in marketing efforts.

Setting the right price for your woodworking services can be tricky, but it’s essential for attracting clients. First, analyze what your competitors charge. This way, you can offer competitive prices without undercutting your quality. Remember, people love a good deal! Use social media to showcase your work and highlight your unique style—who doesn’t want a one-of-a-kind table made by a craftsman with flair?

| Strategy | Description |

|---|---|

| Market Research | Check what others charge for similar services. |

| Unique Selling Point | Highlight what makes your work special. |

| Promotions | Offer discounts for first-time customers. |

Balancing quality with affordability is key. It’s important to show that you care about your craft while still being friendly on the wallet. As the saying goes, “Quality is remembered long after the price is forgotten.” So, create amazing pieces people will want to show off!

Case Studies: Pricing in Real Woodworking Businesses

Examples of successful woodworking pricing strategies. Lessons learned from various woodworking entrepreneurs.

Successful woodworking businesses use smart pricing strategies. For example, one owner charged different rates based on the wood type. This helped them gain profits while keeping customers happy. Another entrepreneur learned to adjust prices seasonally, boosting sales during holidays. From these stories, we find valuable lessons:

- Always know your costs.

- Try different pricing models.

- Listen to customer feedback.

- Stay flexible, especially during busy times.

These tips can help any woodworking business thrive.

What are examples of successful woodworking pricing strategies?

Successful strategies include using tiered pricing and seasonal adjustments. These allow businesses to maximize profits and attract more buyers.

Common Pricing Mistakes to Avoid

Identifying pitfalls in setting prices for woodworking projects. How to assess and adjust prices based on market feedback.

Avoiding common pricing mistakes is crucial for woodworking projects. Watch out for these pitfalls:

- Underpricing your work due to lack of confidence.

- Ignoring labor and material costs.

- Not considering market demand and competition.

Always assess your prices after market feedback. You can adjust based on customer reactions. Keep track of your sales. This will help you see if your prices need a change. Remember, pricing is not just about numbers; it reflects the value of your craft.

What should you avoid when pricing woodworking projects?

Avoid underpricing due to fear and ignoring material costs. This can lead to losses and frustration.

How can I adjust my prices effectively?

Adjust prices based on buyer feedback and market trends. Check what others charge and stay flexible.

Conclusion

In conclusion, a woodworking pricing guide helps you set fair prices for your projects. It’s vital to consider materials, time, and skill level. Understanding these factors ensures you earn what you deserve. Next, check online resources or books to learn more about pricing. This knowledge will help you succeed in your woodworking journey. Happy crafting!

FAQs

What Factors Influence The Pricing Of Custom Woodworking Projects?

The price of custom woodworking projects depends on several things. First, we think about the materials used, like wood type and quality. Next, the size and complexity of the project matter. If it needs special designs or tools, that can make it more expensive. Finally, the skill and experience of the woodworker can affect the cost too.

How Do The Prices Of Different Types Of Wood Affect The Overall Cost Of A Woodworking Project?

The price of wood affects how much your project will cost. Some woods, like oak, are more expensive than plywood. If you choose cheaper wood, you save money. But if you use a fancy wood, you might spend more. So, picking the right wood helps decide your total cost.

What Are The Average Labor Costs Associated With Woodworking And How Can They Vary By Region?

The average labor costs for woodworking can be around $20 to $50 per hour. This can change based on where you live. In big cities, costs are often higher. In smaller towns, you might pay less. So, if you need woodworking help, check prices in your area!

How Can A Woodworking Business Effectively Price Its Services To Remain Competitive While Ensuring Profitability?

To price our woodworking services, we can start by looking at what other businesses charge. We should think about our costs, like materials and tools, to make sure we make money. We can also ask customers what they think is fair. Offering good quality and great service can help us stand out. Finally, if we offer special deals or discounts, we can attract more customers.

What Pricing Strategies Can Be Used To Determine The Cost Of Diy Woodworking Plans Or Kits?

To price DIY woodworking plans or kits, we can use different strategies. First, we can look at what others charge for similar plans or kits. This is called market price. Second, we can decide how much it costs to make the kit and add a little extra for profit. Third, we can think about how much people are willing to pay. Finally, we can run special offers or discounts to attract more buyers.

Resource:

-

calculate your labor cost: https://www.thewoodwhisperer.com/articles/charging-for-your-work/

-

pricing your woodworking business: https://www.woodworkersjournal.com/pricing-your-work/

-

different types of wood and their cost: https://www.popularwoodworking.com/techniques/choosing-the-right-wood/

-

marketing handmade woodworking projects: https://www.shopify.com/blog/handmade-marketing