Have you ever faced a frustrating situation where your nail gun just won’t work? It’s a common problem, especially when the o-ring wears out. Many people don’t realize how simple it can be to replace a nailer o-ring. Just a few steps can save you time and money.

Imagine you’re in the middle of a project. You have all your materials laid out and plans ready. Suddenly, your nail gun starts leaking air. What do you do? This can really put a damper on your work.

Replacing the nailer o-ring is easier than you think. With the proper guidance, you can get your nail gun working like new again. Plus, you’ll gain confidence in fixing tools yourself.

Did you know that a small o-ring can make such a big difference? It’s true! A tiny rubber ring helps keep everything sealed and working smoothly. Let’s explore how to replace a nailer o-ring and get back to your project in no time.

Table of Contents

How To Replace Nailer O-Ring: A Step-By-Step Guide

How to Replace Nailer O-Ring

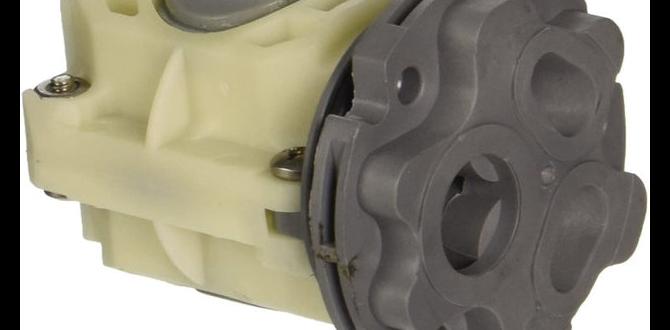

Replacing the o-ring in your nailer can save you money and frustration. First, gather the right tools, like a wrench and replacement o-ring. With a few simple steps, you can take apart your nailer and swap out the old o-ring. Did you know that a worn o-ring can cause leaks? This issue can lead to inefficient work. Learning to replace it easily keeps your nailer in great shape. Why not give it a try? It’s simpler than you think!Understanding the Nailer O-Ring

Importance of the ORing in nail guns. Common signs of a wornout ORing.The O-ring in a nail gun is a small but mighty hero. It helps keep air sealed in, making sure your nailer works without a hitch. If this little ring wears out, you might see some signs that it’s time for a change. You could notice the nailer leaking air, or nails might not drive in properly. Look for these clues:

| Signs of Worn-out O-Ring | Explanation |

|---|---|

| Email Air Leaks | Look out for hissing sounds; it’s like your nailer is trying to tell you something! |

| Nails Not Driving | If your nails are going on strike, they might need some help! |

| Inconsistent Power | One minute it works, the next it doesn’t. It’s like playing Whac-A-Mole! |

Knowing these signs can save you frustration and keep your nailer in tip-top shape. Remember, a small part can make a big difference!

Tools and Materials Needed

List of essential tools for replacement. Recommended materials for the process.Before you start, gather all your tools. You will need:

- A wrench to loosen parts.

- A screwdriver for easy access.

- A replacement o-ring that fits your nailer.

- Clean cloths to wipe away dirt.

It’s also a good idea to have:

- Lubricating oil to help parts move smoothly.

- A container for small screws.

These items will help make your job easier and faster!

What tools do I need to replace a nailer o-ring?

For replacing a nailer o-ring, you will need basic tools like a screwdriver and a wrench. Make sure to have the right size o-ring for your nailer. Keeping everything organized saves time and effort!

Safety Precautions

Key safety measures to take before starting. Importance of proper equipment handling.Before diving into your nailer adventure, safety first! Always wear goggles to keep your eyes safe from flying bits. Gloves are also a must to protect your hands. Think of it as a superhero suit for your fingers! Proper equipment handling is crucial. Make sure your tools are in good shape. A well-maintained nailer is like a happy puppy—it works better!

| Safety Measure | Why it Matters |

|---|---|

| Wear Eye Protection | Prevents injury from debris |

| Use Gloves | Keeps hands safe and clean |

| Inspect Tools | Ensures proper function |

These tiny steps can make a big difference. Think of them as your safety ticks before getting to work. Happy tinkering!

Detailed Steps to Replace the Nailer O-Ring

Stepbystep guide on disassembling the nailer. How to remove the old ORing properly. Instructions for installing the new ORing.Replacing a nailer o-ring is simple. Follow these steps to do it right:

- First, unplug the nailer and release any air pressure.

- Then, remove the housing screws to open the nailer.

- Carefully lift the cover to expose inner parts.

- Next, locate the old o-ring and take it out gently.

- Now, place the new o-ring in the same spot.

- Finally, reassemble the nailer and test it.

Remember, a good seal keeps your nailer working perfectly!

How can I tell if my o-ring needs replacement?

If you see air leaking or if your nailer doesn’t work well, it’s time to change the o-ring!

Testing the Nailer After Replacement

Steps to reassemble the nailer correctly. How to perform a functional test to ensure success.After replacing the O-ring, it’s time to put your nailer back together. Start by carefully following these steps. First, reattach all parts in the reverse order of how you removed them. Make sure everything fits snugly—like your favorite pair of shoes! Next, perform a functional test to check if the nailer is working correctly. Simply connect it to your air supply and fire a few practice nails. If it shoots straight, congrats! You’ve done it right. But if it sputters like a sneezy duck, you may need to check your work.

| Step | Action |

|---|---|

| 1 | Reassemble parts in reverse order. |

| 2 | Connect to the air supply. |

| 3 | Test firing with a few nails. |

A successful test means you replaced that O-ring like a pro! Remember, practice makes perfect, just like keeping your socks with their pairs.

Troubleshooting Common Issues

Frequently encountered problems after replacement. Solutions for common troubleshooting scenarios.After replacing the nailer o-ring, you might find a few hiccups along the way. Sneaky air leaks can turn your nailer into a noisy party crasher! If you hear a hissing sound, check those connections; they might be loose.You might have to tighten them up! If your nailer won’t fire, don’t panic! Ensure the o-ring is seated correctly. Just like a good seatbelt, it needs to be snug. Remember, troubleshooting can be tricky, but with a dash of patience, you’ll be back to nailing in no time!

| Common Issue | Solution |

|---|---|

| Air Leak | Tighten connections |

| Nailer Won’t Fire | Check o-ring seating |

| Jams | Clear feed pathway |

| Weak Blows | Inspect air pressure |

Maintenance Tips to Extend O-Ring Life

Best practices for nailer care and upkeep. Advice on frequency of ORing checks and replacements.To keep your nailer happy and working well, regular checks are key! Look at the O-ring every month for wear and tear. If it’s looking sad or cracked, it’s time for a change. Remember, a happy O-ring makes a happy nailer. Think of it as a spa day for your tools! And don’t forget to clean your nailer too. A little TLC goes a long way in keeping things running smoothly.

| Maintenance Task | Frequency |

|---|---|

| Check O-ring | Every month |

| Clean nailer | Every use |

| Replace O-ring | As needed |

Conclusion

In summary, replacing a nailer o-ring is simple. First, gather your tools and find the right o-ring size. Next, follow the steps carefully for removal and installation. Remember to check for leaks after you’re done. By doing this, you can keep your nailer working well. For more tips, check out tutorial videos or guides online!FAQs

Sure! Here Are Five Related Questions On The Topic Of Replacing A Nailer O-Ring:Sure! Here’s a simple answer to your question. When you replace a nailer o-ring, first you need to find the right size o-ring for your tool. Then, unplug the nailer to stay safe. Next, use a small tool to carefully remove the old o-ring. After that, put the new one in its place, and you’re ready to go! Always check if it fits well before using your nailer again.

Sure! Please provide the question you’d like me to answer.

What Tools Are Required To Replace The O-Ring In A Nail Gun?To replace the o-ring in a nail gun, you need a few tools. First, get a screwdriver to open the nail gun. You also need pliers to pull out old parts. A small brush can help clean dirt. Finally, have a new o-ring ready to put in!

How Can I Identify If The O-Ring In My Nailer Is Damaged And Needs Replacing?To check if the O-ring in your nailer is damaged, first, look for any visible cracks or breaks. You can also feel if it is soft or sticky. If your nailer leaks air or you hear a hissing sound, the O-ring might be bad. If you see any of these signs, it’s a good idea to replace it.

What Are The Steps Involved In Disassembling The Nailer To Access The O-Ring?To disassemble the nailer, first, unplug it to stay safe. Next, use a screwdriver to remove the screws on the handle. Then, carefully pull apart the parts to see the inside. Look for the o-ring, which is a small rubber ring. When you’re done, put everything back together in the reverse order.

Are There Specific O-Ring Materials Or Sizes I Should Use For Different Nailer Models?Yes, the o-rings you use depend on your nailer model. Different models need different sizes and materials. You should check your nailer’s manual for the right o-ring. Some common materials are rubber or silicone. Always use the recommended o-rings to keep your nailer working well.

What Maintenance Tips Can Help Prolong The Life Of The O-Rings In My Nail Gun?To keep the o-rings in your nail gun working well, you should clean them regularly. Use a soft cloth to wipe away dirt. Check for any cracks or damage and replace them if needed. Also, add a little oil to the o-rings every few uses to keep them flexible. This way, you can help them last longer!