Have you ever watched a bandsaw in action? It’s fascinating how these machines cut through tough materials with ease. Now, imagine using high tension bandsaw blades. They help the saw perform even better!

High tension bandsaw blades are not just your ordinary blades. They are designed to withstand a lot of pressure while cutting. This means they last longer and give cleaner cuts. Doesn’t that sound cool?

Think about a chef slicing through a thick piece of meat. A regular knife might struggle, while a sharp knife glides right through. That’s similar to how high tension bandsaw blades work compared to traditional ones.

In this article, we’ll explore the magic behind high tension bandsaw blades. We’ll look at why they’re essential for woodworking and metalworking. You might be surprised at what you find!

Table of Contents

High Tension Bandsaw Blades: A Guide To Precision Cutting

High Tension Bandsaw Blades

High tension bandsaw blades are powerful tools used in various cutting tasks. They offer precision and durability, making them ideal for woodworkers and metal fabricators. Did you know that these blades can withstand immense pressure without breaking? They also come in different materials, like carbon and bi-metal, which enhance their performance. With proper maintenance, they last longer and improve cutting quality. Understanding their features helps you choose the best blade for your needs, ensuring smooth and efficient cutting adventures!

What are High Tension Bandsaw Blades?

Definition and purpose of high tension bandsaw blades. Importance of tension in bandsaw blade performance.

High tension bandsaw blades are cutting tools that help slice through tough materials like wood and metal. They work by using a lot of pressure to keep the blade tight, making cuts easier and cleaner. The right amount of tension is crucial because it helps the blade stay straight and lasts longer. A well-tensioned blade can cut faster and improve safety.

What is the purpose of high tension bandsaw blades?

The purpose is to provide precise cuts in various materials. High tension ensures the blade does not bend or break.

Key Points:

- Improves cutting accuracy

- Extends blade life

- Enhances safety during use

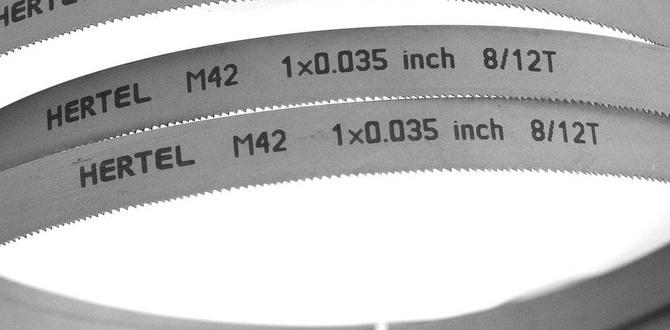

Types of High Tension Bandsaw Blades

Different materials used (carbon steel, bimetal, carbidetipped). Blade teeth configurations and their applications.

High tension bandsaw blades come in various types. Each type has its unique features. The most common materials are:

- Carbon steel: Strong and perfect for softer materials.

- Bimetal: A mix of metals that offers more strength and durability.

- Carbide-tipped: Best for cutting tough materials, lasting much longer.

Blade teeth configuration also matters. Some blades have sharp teeth for faster cuts, while others have wider teeth for cleaner finishes. Choosing the right type helps achieve better results in your projects.

What are the types of high tension bandsaw blades?

There are three main types of blades: carbon steel, bimetal, and carbide-tipped. Each type is designed for specific cutting tasks. Carbon steel is ideal for soft materials, while bimetal and carbide-tipped blades are best for harder cuts.

Benefits of Using High Tension Bandsaw Blades

Advantages in precision and cutting speed. Longevity and costeffectiveness.

Using high tension bandsaw blades comes with great benefits. They help make precise cuts quickly. This boosts speed in any job. They last longer than regular blades, saving money over time. Investing in these blades is smart for both efficiency and cost savings. Here are some advantages:

- Precision: Fewer errors in cuts.

- Speed: Quicker cutting means more work done.

- Longevity: Lasts longer, so fewer replacements needed.

- Cost-Effective: Saves money in the long run.

Why are high tension bandsaw blades important?

High tension bandsaw blades are crucial because they enhance cutting efficiency and reduce waste. With their ability to provide accuracy and speed, they are a favorite among woodworkers and metalworkers alike.

How to Choose the Right High Tension Bandsaw Blade

Factors to consider (material, thickness, and application). Recommended sizes and specifications for different projects.

Choosing the right bandsaw blade can be as tricky as picking a favorite ice cream flavor, especially with so many options available! You need to think about material, thickness, and application. For wood, a different blade works better than for metal. It’s like using a spoon for soup and a fork for pasta, right? Here’s a quick guide:

| Project Type | Recommended Blade Size | Thickness (in mm) |

|---|---|---|

| Wood Cutting | 1/4 inch | 2.0 mm |

| Metal Cutting | 1/2 inch | 3.5 mm |

| Plastic Cutting | 3/8 inch | 1.5 mm |

So, get the right tool, and you’ll be a bandsaw superstar in no time!

Maintaining High Tension Bandsaw Blades

Key maintenance practices to extend blade life. Signs that indicate a blade needs replacing.

Keeping high tension bandsaw blades in good shape is important. Regular checks help blades last longer. Here are some key practices:

- Clean blades after use to remove dust and resin.

- Check tension regularly to maintain straight cuts.

- Lubricate blades to reduce heat and wear.

- Use the right speed for cutting materials.

Look out for signs that it’s time to replace your blade:

- Visible wear or damage.

- Unusual noises during cutting.

- Rough edges on cut materials.

Taking good care of blades makes them last, saving time and money!

What are the signs that a bandsaw blade needs replacing?

Replace your blade if you notice wear, unusual sounds, or rough cuts. These signs mean the blade is not working well anymore.

Common Applications of High Tension Bandsaw Blades

Industries that utilize high tension bandsaw blades (woodworking, metal fabrication, etc.). Specific tasks and materials best suited for these blades.

Many businesses use high tension bandsaw blades. They are perfect for cutting tough materials. Here are some industries that rely on these blades:

- Woodworking: Ideal for slicing thick timber and making furniture parts.

- Metal Fabrication: Great for cutting metal sheets and pipes.

- Construction: Useful for cutting beams and large materials.

- Automotive: Helps slice through engine parts and frames.

These blades work well on hard-to-cut materials like hardwood, steel, and aluminum. They provide precision and smooth finishes. This makes them popular tools in various industries.

What are some common uses for high tension bandsaw blades?

Common uses include cutting wood, metal, and plastic for different projects. They help make furniture, automotive parts, and various construction materials.

FAQs about High Tension Bandsaw Blades

Common questions and misconceptions regarding usage. Troubleshooting tips for common issues.

Many people have questions about how to use high tension bandsaw blades correctly. One common thought is that tighter is always better. That’s not true! If it’s too tight, it can cause damage. If you face issues, like the blade wandering, check the tension and alignment. Also, remember to use the right blade for the material you’re cutting.

| Common Issues | Troubleshooting Tips |

|---|---|

| Blade Wandering | Check the tension and guide alignment. |

| Frequent Breakage | Ensure you’re using the right blade for your material. |

| Uneven Cuts | Inspect the blade sharpness and tension. |

Follow these tips, and you’ll be a bandsaw pro in no time! Just think of your bandsaw as a diva; she has her moods and needs proper care!

Latest Innovations and Trends in Bandsaw Blade Technology

Emerging technologies improving blade performance. Future trends in high tension bandsaw blade manufacturing.

New technologies are making high tension bandsaw blades work better than ever. Improvements in materials are helping blades cut faster and last longer. For example, new coatings make blades resistant to wear and tear. Future trends in blade manufacturing will focus on:

- Eco-friendly materials

- Smart blade technology

- Customization options for specific tasks

These changes hope to meet the needs of various woodworkers and industry users. Better blades mean smoother cuts and more efficiency. It’s an exciting time in the world of bandsaw blades!

What are the future trends for bandsaw blades?

Future trends include smart technology, eco-friendly materials, and blade customization. These innovations aim to enhance performance and meet diverse user needs.

Conclusion

In conclusion, high tension bandsaw blades are strong and efficient tools for cutting various materials. They offer precise cuts and help you work faster. You should regularly inspect and maintain them for the best performance. If you want to learn more, check out guides on proper use and care. These will help you make the most of your bandsaw blade experience!

FAQs

Sure! Here Are Five Related Questions On The Topic Of High Tension Bandsaw Blades:

High tension bandsaw blades are strong blades used in big saw machines. They help cut through tough materials like wood and metal. These blades are pulled tight, which makes them better at cutting. You have to be careful when using them because they can be dangerous. Always follow safety rules and wear protective gear!

Sure! Please give me the question you want answered.

What Are The Advantages Of Using High Tension Bandsaw Blades Compared To Standard Bandsaw Blades?

High tension bandsaw blades are stronger than standard blades. They can cut through harder materials easily. You get smoother and cleaner cuts. They last longer, so you don’t have to change them as often. This means you save time and money!

How Do You Determine The Appropriate Tension Level For A High Tension Bandsaw Blade?

To find the right tension for a high tension bandsaw blade, you start by checking the blade’s instructions. You can tighten the blade until it feels firm but not too tight. If it makes a dull sound when you tap it, the tension might be too low. If it bends because it’s too tight, you’ll need to loosen it a bit. Experimenting gently helps you get it just right!

What Types Of Materials Can Be Efficiently Cut Using High Tension Bandsaw Blades?

You can cut many types of materials with high tension bandsaw blades. They work well on wood, metal, and plastic. If you want to cut thick materials, these blades are great. They make clean and smooth cuts. Remember to use the right blade for the best results!

What Maintenance Practices Are Essential For Ensuring The Longevity And Performance Of High Tension Bandsaw Blades?

To keep high tension bandsaw blades working well, you need to clean them regularly. Use a brush to remove sawdust and debris. Make sure the tension is just right, not too tight or too loose. You should also check for any damage or wear and replace the blade if needed. Finally, oil the blade to keep it moving smoothly.

How Does Blade Width And Tooth Design Affect The Performance Of High Tension Bandsaw Blades In Different Cutting Applications?

The width of a bandsaw blade helps decide how thick the material can be cut. A wider blade is better for cutting strong or thick items. The teeth design matters too. Sharp teeth cut faster, while teeth with different shapes help with various materials. Choosing the right width and design lets us cut better and easier!