Quick Summary:

A finishing nailer is your best friend for cabinet installation, offering speed, precision, and clean results. This guide ensures you choose the right one and use it effectively for a professional cabinet finish, even if you’re a beginner.

Hey DIYers! Jack Shaffer, your guide from Nailerguy, here. Installing cabinets can feel like a big project, but with the right tools, it’s totally achievable and even satisfying. One tool that makes a huge difference is a finishing nailer. If you’ve ever struggled with trying to hold cabinets perfectly in place while also trying to secure them, you know it can be a wrestling match. A finishing nailer helps you do both jobs with ease, leaving you with beautiful, secure cabinets and minimal fuss. This guide is designed to take the guesswork out of using a finishing nailer for cabinet installation, making sure you get those cabinets up right the first time.

We’ll cover everything from picking the perfect nailer to making sure every nail goes precisely where you want it. Get ready to tackle your cabinet project with confidence!

Table of Contents

Why a Finishing Nailer is a Cabinet Installer’s Secret Weapon

When it comes to attaching cabinets to walls or joining cabinet pieces together, precision and speed are key. Traditional methods, like using screws or hammer and nails, can be time-consuming and sometimes leave visible marks or even split the wood. That’s where a finishing nailer shines.

A finishing nailer drives thin, slender nails (called “finish nails”) that are designed to hold pieces securely without causing significant damage to the wood surface. Unlike framing nailers that shoot thicker, longer nails for structural work, finish nailers are built for more delicate tasks. For cabinet installation, this means:

- Speed: Quickly attach cabinets to wall studs or secure face frames without fumbling.

- Cleanliness: The small nail heads are less noticeable and easier to fill or hide.

- Accuracy: You can place nails precisely where needed, ensuring a strong hold without compromising aesthetics.

- Reduced Wood Damage: Less likely to split thin cabinet materials or leave large gashes.

- One-Handed Operation: Many models allow you to free up your other hand for positioning or support.

Think of it as a power-driven staple designed for woodworking trim and assembly. It’s the difference between professional-looking results and something that looks like it was put together by a less experienced hand.

Choosing the Right Finishing Nailer for Cabinet Installation

Not all finishing nailers are created equal, and the best one for your cabinet project depends on a few factors. Here’s what to consider:

1. Power Source: Pneumatic vs. Battery vs. Electric

This is the first big decision. Each has its pros and cons:

- Pneumatic (Air-Powered):

- Pros: Generally lighter, more powerful, and less expensive upfront. They offer consistent power delivery.

- Cons: Requires an air compressor and hose, which adds bulk, noise, and setup time. You’re tethered to the compressor.

- Battery-Powered (Cordless):

- Pros: Ultimate portability and freedom of movement. No cords or hoses. Great for jobs where power outlets are scarce or you need to move around a lot. Modern battery tech is very impressive.

- Cons: Can be heavier and more expensive. Battery life and consistent power during heavy use can be concerns for some models.

- Electric (Corded):

- Pros: No batteries to charge, no compressor needed. Typically the most affordable option.

- Cons: You’re tethered by a power cord, which can be cumbersome around a job site. May lack the power for very dense woods.

For cabinet installation, especially if you’re doing multiple cabinets or a full kitchen, the freedom of a cordless model is often preferred. However, if you already have a compressor or are on a tighter budget, a pneumatic option is excellent.

2. Gauge and Nail Size

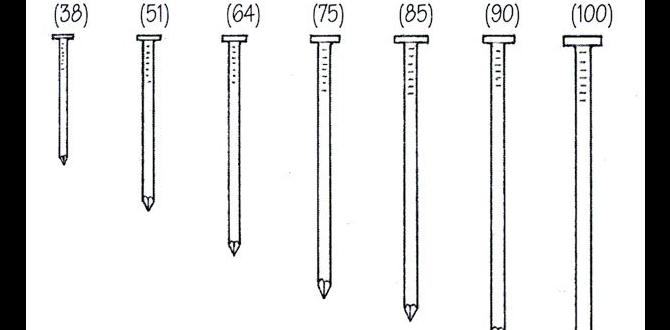

Finish nailers specify the “gauge” of the nail they use. A lower gauge number means a thicker nail. For cabinet installation, you’ll typically want a nailer that accepts:

- 16-Gauge: This is the sweet spot for most cabinet work. The nails are thin enough to prevent splitting but strong enough to hold cabinets securely. They leave a small, easily concealable hole.

- 18-Gauge: These nails are even thinner and leave very small, almost invisible holes. They are great for attaching thin trim or molding to cabinets, or for very delicate cabinet parts where aesthetics are paramount. They might not be robust enough for the main structural attachment of heavy cabinets.

Recommendation for Cabinets: A 16-gauge finishing nailer is generally the most versatile and recommended choice for cabinet installation. You’ll want to ensure your nailer can drive nails between 1 ¼ inches and 2 ½ inches long. Longer nails are great for driving through cabinet boxes into wall studs.

3. Features to Look For

- Adjustable Depth of Drive: This is crucial. It allows you to control how deep the nail sinks into the wood. You’ll want to be able to set it so the nail head is flush with the surface or slightly countersunk, but not so deep that it punches through or causes major damage.

- Tool-Free Jam Release: Jams are inevitable, but a tool-free release mechanism makes clearing them quick and easy, saving you frustration.

- No-Mar Tip: Some nailers come with a rubber or plastic tip that protects the wood surface from accidental dings and scratches. This is a lifesaver when working with finished cabinet surfaces.

- Swiveling Belt Hook: Handy for keeping the tool close at hand when you need both hands for positioning.

- Ergonomics: Since you might be holding the nailer for extended periods, a comfortable grip and balanced weight are important.

Essential Safety Gear for Nailer Use

Working with any power tool, especially one that drives sharp objects at high speed, requires attention to safety. Never skip these steps!

- Safety Glasses: This is non-negotiable. Always wear ANSI Z87.1 rated safety glasses or goggles. Flying debris or accidental nail ricochets can cause serious eye injury.

- Hearing Protection: While finish nailers are generally quieter than framing nailers, prolonged use can still impact your hearing. Earplugs or earmuffs are a good idea.

- Work Gloves: Protect your hands from splinters and minor impacts.

- Closed-Toe Shoes: Protect your feet from dropped tools or stray nails.

- Know Your Tool: Read the manufacturer’s manual thoroughly. Understand how to load it, operate it safely, and what to do in case of a jam.

- Never Point at Yourself or Others: Treat the nailer as if it were always loaded and ready to fire.

- Be Aware of Your Fingers: Keep your fingers away from the nose of the nailer when it’s armed.

- Secure the Workpiece: Ensure the cabinet or material you are nailing into is stable.

- Turn Off and Disconnect: Always disconnect the power source (unplug electric, detach battery, or disconnect air hose) before performing any maintenance, loading nails, or when the tool is not in use.

For more detailed safety guidelines on power tools, the Occupational Safety and Health Administration (OSHA) provides comprehensive information on tool safety standards, which is a great resource to bookmark.

How to Use a Finishing Nailer for Cabinet Installation: Step-by-Step

Alright, let’s get down to the practical part. Here’s how to use your finishing nailer effectively and safely for cabinet installation.

Step 1: Prepare Your Workspace and Tools

Before you even pick up the nailer, get organized.

- Gather Your Tools: Finishing nailer, appropriate nails (16-gauge, 1 ¼” to 2 ½”), air compressor and hose (if pneumatic), power source (battery or cord), safety gear, level, stud finder, measuring tape, pencil, caulk.

- Check Your Nailer: Ensure it’s clean and functioning properly. Load the correct size and type of nails according to the manufacturer’s instructions.

- Prepare the Wall: Use a stud finder to locate wall studs where you’ll be mounting the cabinets. Mark their locations lightly with a pencil. Cabinets must be secured to studs for safety and stability.

- Position the Cabinet: With help if needed, place the cabinet in its final position. Use shims to ensure it’s level and plumb (perfectly vertical). A cabinet that isn’t level will look crooked and doors may not close properly.

Step 2: Set the Depth of Drive

This is where practice makes perfect. You want the nail head to be slightly below the surface of the wood (countersunk) so you can fill it with putty, but not so deep that it breaks through the veneer or causes a large dent.

- Test on Scrap Wood: Find a piece of scrap wood that matches the cabinet material.

- Start with a Mid-Setting: Adjust the depth setting on your nailer to a medium level.

- Fire a Nail: Hold the nailer flush against the scrap wood and drive a nail.

- Inspect: Check how deep the nail went. If it’s too shallow, increase the depth setting (or air pressure if pneumatic). If it’s too deep, decrease the setting.

- Repeat: Fire a few more nails until you achieve the desired depth consistently. This ensures you won’t damage your actual cabinets.

Step 3: Securing the Cabinet to the Wall

Position the cabinet precisely. You’ll be driving nails through the cabinet’s back or through the cabinet’s internal structure into the wall studs.

- Align and Hold: Ensure the cabinet is perfectly positioned and held in place (you might need a helper or temporary bracing).

- Place the Nailer: Press the nose of the finishing nailer firmly against the cabinet where you want to drive a nail. Make sure it’s contacting the wood surface.

- Engage the Safety Contact and Pull the Trigger: Most nailers have a safety mechanism (the “contact trip” or “safety nose”) that must be pressed against the wood before you pull the trigger. This prevents accidental firing.

- Drive the Nail: Fire one nail into a stud, preferably in a less visible area first.

- Check the Hold: Gently try to wiggle the cabinet. If it feels secure, you’re on the right track.

- Drive Additional Nails: Drive more nails every 16-24 inches along the top and bottom into the wall studs. Also, drive nails through the cabinet’s internal support structures (like where shelves attach) into the studs. This provides a strong, secure mounting.

- Use Pilot Holes for Face Frames (Optional but Recommended): For hardwood face frames, especially if they are thin, you might consider drilling small pilot holes before nailing to prevent any possibility of splitting. This is less for structural hold and more for aesthetic perfection.

Pro Tip: For heavier cabinets or to ensure maximum security, drive nails through the cabinet’s back into the studs, and also through the face frame into the adjacent cabinet if they are being joined side-by-side.

Step 4: Joining Cabinets Together

When installing multiple cabinets side-by-side, you’ll want to join them securely to create a seamless unit.

- Position Adjacent Cabinets: Place two cabinets next to each other, ensuring their face frames are perfectly flush and aligned.

- Clamp Them Together: Use pipe clamps or bar clamps to pull the cabinets tightly together. This is a critical step for a clean joint.

- Nail Through the Face Frames: With the cabinets clamped tightly, drive 16-gauge finish nails through the face frame of one cabinet into the face frame of the other.

- Spacing: Place nails about 6-8 inches apart along the length of the joint.

- Depth is Key: Ensure your nailer is set so the nails sink flush or slightly below the surface of the face frame.

- Remove Clamps and Inspect: Once nailed, remove the clamps and check the joint. It should be tight and flush.

Some installers prefer to attach cabinets to the wall first, then join them. Others prefer to join cabinets together on the floor, then lift and install the whole unit. Both methods work, but joining them tightly first before mounting can sometimes lead to a more consistent flush. For structural integrity, both the wall attachment and the side-by-side join are essential.

Step 5: Finishing Touches

Once all cabinets are securely installed and joined, it’s time to make them look perfect.

- Fill Nail Holes: Use a wood putty or filler that matches your cabinet’s finish. Apply it with a putty knife, pressing it into the nail holes.

- Wipe Away Excess: Before the putty dries, wipe away any excess with a clean cloth.

- Sand (If Necessary): Once the putty is completely dry, you can lightly sand the filled holes smooth if needed. Be careful not to sand the surrounding cabinet finish.

- Caulk Gaps: Apply a bead of paintable caulk along any gaps between the cabinets and the wall, or between cabinets themselves, for a clean, finished look.

Troubleshooting Common Finishing Nailer Issues

Even with the best tools, occasional hiccups occur. Here are some common problems and how to fix them:

| Problem | Possible Cause | Solution |

|---|---|---|

| Nail not firing | – Lack of power (air pressure low, battery low) | – Check air compressor pressure or battery charge. |

| – Safety contact not engaged | – Press the nose of the nailer firmly against the workpiece before pulling the trigger. | |

| – Nailer jam | – Disconnect power, clear the jam (refer to manual). | |

| Nail fires but isn’t driven deep enough | – Depth of drive setting too high | – Increase depth of drive setting or air pressure. |

| – The workpiece material is too dense | – For very hard woods, you might need to increase air pressure slightly or pre-drill a pilot hole (though be careful not to make it too big). | |

| Nail fires too deep / goes through material | – Depth of drive setting too low |