Build your own sturdy wooden ladder with these genius woodworking projects! Discover simple, step-by-step guides for creating reliable ladders for home use, from compact step ladders to robust extension models. Get ready to tackle your DIY tasks with confidence!

Ever found yourself needing a ladder and wishing you had one readily available? Maybe you’re tired of wobbly, old ladders that make you nervous. Building your own wooden ladder might seem like a big project, but it’s totally achievable, even for beginners!

You’ll be surprised at how straightforward it can be with the right guidance. We’re going to walk through some smart woodworking projects that will help you create a strong, safe, and good-looking ladder. No more guesswork – just clear steps and helpful tips.

Ready to build something truly useful and impressive? Let’s dive into some genius designs that will elevate your DIY game!

Table of Contents

Why Build Your Own Wooden Ladder?

There are several great reasons to consider building your own wooden ladder. For starters, you gain complete control over the materials and design, ensuring it meets your specific needs and safety standards. Plus, it’s a fantastic woodworking project that can be incredibly rewarding!

Customization for Your Needs

Pre-made ladders often come in standard sizes. But what if you need something a little taller, a bit shorter, or with a specific kind of rung spacing? Building your own lets you tailor every dimension. Need a small, sturdy step stool for your kitchen? Or a tall, stable ladder for reaching high shelves in the garage? You can design it to fit perfectly.

Cost-Effectiveness

While you’ll invest in materials, building a ladder yourself can often be more economical than buying a high-quality wooden ladder. You can select durable wood species that might be pricier in manufactured units, and you avoid retail markups.

Unmatched Durability and Strength

When you build it yourself, you know exactly how it’s put together. You can choose strong, appropriate wood and use robust joinery techniques to ensure your ladder is built to last. This means it can be safer and more reliable than many store-bought options, especially those made from cheaper materials.

The Satisfaction of DIY

There’s a special kind of pride that comes from using something you’ve made with your own hands. A handmade wooden ladder isn’t just a tool; it’s a testament to your skills and hard work. It’s a functional piece of art for your home or workshop.

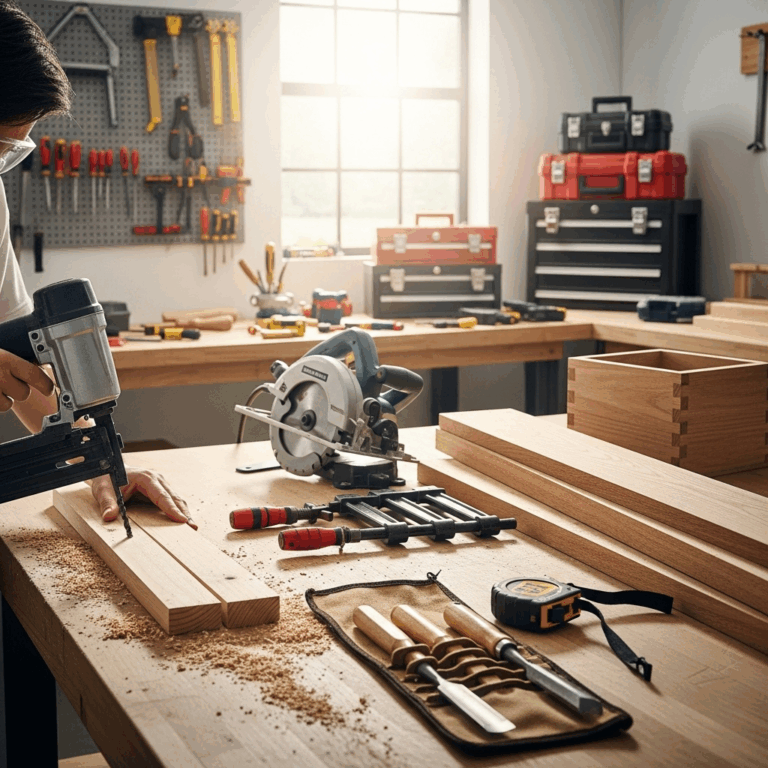

Essential Tools and Materials

Before we get to the exciting designs, let’s make sure you have the right gear. Having these on hand will make your ladder-building journey smooth and safe.

Key Tools You’ll Need:

- Measuring Tape: Precision is key for ladder construction.

- Pencil: For marking your cuts.

- Saw: A circular saw or miter saw will make cutting your lumber quick and accurate. A handsaw can work for simpler designs, but power tools are much faster.

- Drill: For pre-drilling holes and driving screws.

- Clamps: Essential for holding pieces together while you work and for glue-ups.

- Sander: To smooth out rough edges and create a comfortable finish. (Orbital sander or sandpaper would work.)

- Safety Glasses: Always protect your eyes!

- Work Gloves: To protect your hands.

- Square: To ensure your cuts and joints are perfectly at 90 degrees.

Recommended Materials:

- Wood: Durable hardwoods like oak, ash, or maple are excellent choices for strength and longevity. Pine or fir can be used for less demanding applications, but choose clear, knot-free lumber for the best structural integrity. For step ladders, a thickness of 1×4 or 1×6 is common for the sides (stringers) and rungs. For larger extension ladders, you might consider 2×4 or 2×6. Always ensure your wood is dry and free from cracks or large knots. You can learn more about selecting lumber at the Woodworking Handbook’s wood selection guide.

- Screws: High-quality wood screws, preferably exterior-grade or coated for durability. Choose screws long enough to provide a strong hold without splitting the wood (e.g., 2.5-inch or 3-inch screws for 1-inch thick lumber).

- Wood Glue: A strong, waterproof wood glue will add significant strength to your joints.

- Sandpaper: Various grits (e.g., 80, 120, 220) for smoothing.

- Finish: Varnish, polyurethane, or exterior paint to protect the wood from the elements.

Genius Ladder Designs for Your Home

Let’s explore some popular and practical woodworking projects for building wooden ladders. We’ll start with simpler designs and move to slightly more involved ones.

1. The Classic A-Frame Step Ladder (Beginner-Friendly)

This is a fantastic starter project. An A-frame ladder is self-supported, stable, and relatively easy to build. It’s perfect for indoor tasks or light outdoor work.

Design Overview:

An A-frame ladder consists of two identical sides that spread open to form an ‘A’ shape. Rungs connect the two sides, providing steps. A hinge mechanism at the top allows it to fold for storage.

Materials for a ~4-foot A-Frame Ladder:

- (2) 1×4 boards, 8 feet long (for outer legs/sides)

- (2) 1×4 boards, 6 feet long (for inner legs/sides)

- (4-5) 1×4 boards, 2 feet long (for rungs)

- (2) 1×4 board, 1.5 feet long (for top support/cap)

- Heavy-duty hinges (2)

- Strong wood screws (2.5 inches)

- Wood glue

Building Steps:

- Cut Your Lumber:

- Cut the two 8-foot 1x4s into two 4-foot sections each (these are your outer legs).

- Cut the two 6-foot 1x4s into two 3-foot sections each (these are your inner legs).

- Cut your rung boards to the desired width between the legs. For a 4-foot ladder, you might aim for about 18-20 inches between the legs. Ensure the rungs are consistent.

- Cut the top support pieces – these will span the top of the outer legs.

- Prepare the Legs:

- On the inside face of each 4-foot outer leg, mark where your rungs will go. Start about 10 inches from the bottom and space Rungs about 10-12 inches apart.

- On the inside face of each 3-foot inner leg, mark the same rung locations.

- Attach the Rungs:

- Apply wood glue to the ends of a rung board.

- Position the rung between the outer and inner legs at your marked locations. Ensure the legs are resting flat on your workbench.

- Pre-drill holes through the outer legs into the rung ends, and through the inner legs into the rung ends.

- Drive screws to secure the rungs. Use clamps to hold everything in place while you work.

- Repeat for all rungs, ensuring each rung is level and securely attached.

- Assemble the ‘A’ Frame:

- Lay one set of leg/rung assemblies flat.

- Apply glue to the top edges of the outer legs.

- Attach the top support pieces across the top of the outer legs using screws and glue.

- Repeat for the other side.

- Join the Two Sides:

- With the two leg assemblies standing upright and spread to your desired ‘A’ angle, attach the heavy-duty hinges at the very top where the inner legs meet. This allows the ladder to fold.

- Ensure the hinges are securely fastened to both inner legs.

- Add Support and Finish:

- Consider adding gussets (triangular wood pieces) at the leg-to-rung joints for extra strength, especially on the bottom rung.

- Sand all surfaces smooth, paying attention to edges where you’ll grip.

- Apply your chosen finish to protect the wood and give it a nice look.

2. Sturdy Utility Step Ladder (Slightly More Advanced)

This design is a bit more robust, often featuring wider steps and a more solid construction. It’s great for workshops or areas where you might need to carry tools up and down.

Design Overview:

Similar to the A-frame but often wider and built with thicker lumber (like 2x4s for legs and 2x6s for steps). It might include a tool tray at the top.

Materials:

- 2×4 lumber for legs and internal supports

- 2×6 lumber for wider steps

- Heavy-duty screws or lag bolts

- Wood glue

- Metal brackets (optional, for extra reinforcement)

Key Differences & Enhancements:

- Materials: Opt for 2x4s for the main leg structures and 2x6s for the treads. This provides greater strength and stability.

- Joinery: Consider using pocket holes or mortise and tenon joints for even stronger rung connections. For beginner comfort, robust screw and glue joinery is still excellent.

- Wider Treads: The 2×6 lumber allows for wider, more comfortable steps.

- Top Tool Tray: A simple box-like tray can be added to the top of the inner frame to hold tools and supplies.

- Bracing: Add diagonal bracing between the legs or at the back of the steps for increased rigidity.

The building process is similar to the A-frame, but you’ll be working with thicker material. This necessitates stronger fastening methods, possibly larger screws or lag bolts, and careful pre-drilling to avoid splitting the wood. Always check your local building codes or resources like NACHI’s ladder safety guidelines for best practices in construction and safety.

3. The Simple Folding Monkey Ladder (for Attic Access)

A monkey ladder is a straightforward, straight ladder that folds up against a wall or ceiling opening. It’s perfect for accessing attics or lofts without a permanent staircase.

Design Overview:

This is a single, straight ladder with rungs. It’s designed to be hinged at the top to fold away. It often requires a secure mounting point and a mechanism to lock it in place when deployed.

Materials:

- 2×4 or 2×6 lumber for the side rails (stringers) – length depends on your ceiling height.

- 1×4 or 2×4 lumber for the rungs.

- Heavy-duty hinges (at least 2).

- Sturdy screws or lag bolts.

- Optional: eye bolts and a latching mechanism to secure the ladder when folded down.

Building Steps (Simplified):

- Determine Length: Measure the distance from your ceiling opening to the floor. Add a foot or two so you can comfortably step off.

- Cut Rails: Cut two pieces of 2×4 (or 2×6) to your determined length for the side rails.

- Cut Rungs: Cut your rung material to the desired width, usually around 16-20 inches.

- Mark and Attach Rungs: Mark rung positions on the inside of the side rails, spaced about 12 inches apart. Ensure the rungs are perpendicular to the rails. Attach the rungs using strong wood glue and screws. Pre-drilling is essential here, especially with 2x lumber. You can use pocket holes for a cleaner look and more secure joint.

- Attach Hinges: At the top end of each side rail, attach heavy-duty hinges. These will anchor to your ceiling structure or a reinforced joist.

- Mounting: You’ll need to install a secure framing or reinforcement in your ceiling where the ladder will pivot. Install the other side of the hinges to this structure.

- Securing: When the ladder is down, it needs to be stable. A simple method is to use eye bolts on the ladder rails and corresponding hooks on the floor or wall, pulled taut with rope. Or, a more robust latching system can be mounted.

- Safety Check: Ensure all joints are solid, hinges are secure, and the locking mechanism is reliable.

Building a monkey ladder requires careful consideration of where it will be hinged and how it will be secured. It’s crucial that the ceiling joists are strong enough to support the hinges and the weight of the ladder plus a person. For critical structural components, consulting a professional or referring to building standards is always a good idea.

Safety First! Essential Considerations for Ladder Building

Building a ladder is exciting, but safety has to be your top priority. A poorly built ladder can be dangerous. Here are some crucial points to keep in mind:

- Wood Quality: Always choose straight, knot-free lumber. Knots create weak points where the wood can break.

- Proper Joinery: Don’t skimp on fasteners and glue. Screws and glue are your friends. Consider using stronger joinery if you have the skills.

- Load Capacity: Design your ladder with its intended use and projected weight in mind. A ladder for painting walls needs to be stronger than one for reaching a low shelf. You can find general guidelines for load capacity and ladder construction from organizations like the Occupational Safety and Health Administration (OSHA).

- Rung Spacing and Depth: Ensure rungs are evenly spaced (typically 10-14 inches apart) and deep enough (at least 3.5 inches) for comfortable and secure footing.

- Angle of Lean: For any ladder that leans against a surface (like an extension ladder, though we haven’t detailed that complex build here), the ideal angle is about 75 degrees. For A-frame ladders, ensure the spread is stable.

- Smooth Finish: Sand down all edges and surfaces to prevent splinters.

- Regular Inspection: Periodically check your handmade ladder for any signs of wear, loose fasteners, or cracks.

Choosing the Right Wood for Your Ladder

The type of wood you select plays a huge role in the safety and longevity of your ladder. Here’s a quick guide to common choices:

| Wood Type | Pros | Cons | Best For |

|---|---|---|---|

| Oak | Very strong, durable, good shock resistance, beautiful grain. | Heavy, can be expensive, harder to work with. | Heavy-duty utility ladders, traditional A-frames. |

| Ash | Strong, flexible, good shock absorption, similar to oak. | Can be prone to insect damage if not sealed well. | High-stress applications, general purpose ladders. |

| Maple | Hard, strong, smooth finish, good wear resistance. | Can be a bit heavier than pine, requires sharp tools. | Indoor step ladders, attractive finishes. |

| Pine (or Fir) | Lightweight, affordable, easy to work with. | Softer, can dent or scratch more easily, prone to knots. Choose clear, knot-free lumber! | Light-duty indoor ladders, step stools, projects where weight is a concern. |

When buying lumber, always look for pieces that are straight, kiln-dried (to prevent warping), and free from large knots, cracks, or other defects, especially on the parts that bear the most weight (legs and rungs).

FAQs About Building Wooden Ladders

Got questions? We’ve got answers!

Q1: What is the safest way to join ladder rungs to the side rails?

For beginners, the most straightforward and safe method is using a combination of strong wood glue and sturdy wood screws. Pre-drilling pilot holes slightly smaller than your screws is crucial to prevent splitting the wood. For advanced users, mortise and tenon joints or lap joints secured with glue and screws/pegs offer superior strength.

Q2: How far apart should the rungs on a ladder be?

Rungs are typically spaced between 10 and 14 inches apart, center-to-center. This spacing allows for comfortable climbing for most adults. Ensure they are consistently spaced along the entire length of the ladder.

Q3: What’s the best wood for a ladder?

Hardwoods like oak, ash, and maple are excellent choices for their strength and durability. Softwoods like clear, knot-free pine or fir can be used for lighter-duty ladders, but they require more careful selection to ensure structural integrity.

Q4: How do I make sure my homemade ladder is safe to use?

Always use high-quality materials, ensure all joints are strong, sand down all surfaces to prevent splinters, and inspect your finished ladder thoroughly before its first use. If you’re unsure about structural integrity, consider consulting a professional or referring to safety standards like those published by OSHA.

Q5: Can I use a standard circular saw to cut ladder parts?

Yes, absolutely! A circular saw is very capable of making the straight cuts needed for ladder legs and rungs. For the most precise, repeatable cuts, especially for angles on A-frame ladders, a miter saw is ideal, but a circular saw will certainly get the job done effectively.

Q6: How can I make my wooden ladder fold for easier storage?

For an A-frame ladder, heavy-duty hinges at the apex of the ‘A’ allow the two sides to fold together. For a straight ladder intended to fold against a wall (like an attic ladder), similar hinges are used at the top to pivot it upwards.

Conclusion: Climb Higher with Your Handmade Ladder!

Building your own wooden ladder is a truly rewarding woodworking project that provides a functional, reliable, and custom tool for your home or workshop. You’ve learned about the essential tools and materials, explored genius designs from a simple A-frame to a practical attic ladder, and most importantly, emphasized safety and material selection.

Remember, precision in your measurements and cuts, combined with strong joinery, will result in a ladder you can trust. Don’t be afraid to start simple. The joy of building something useful and durable with your own hands is immense. So gather your materials, fire up your tools safely, and get ready to build a ladder that’s not just a tool, but a testament to your DIY skills!