Have you ever wondered how buildings stay standing without falling? It all comes down to wood structure load. This topic may sound complicated, but it’s really about how much weight wood can hold. Imagine a tree in the forest. It has to hold up its branches, leaves, and maybe even some snow! The same idea applies to wood in construction.

Wood is a popular choice for building homes and parks. It’s strong, yet light, making it perfect for many structures. But did you know that not all wood can handle the same weight? Some woods are tougher than others. For instance, oak can often bear more load than pine.

Understanding wood structure load helps builders create safe places for people. When a building’s load is too heavy, it can collapse. Think about that the next time you see a wooden bridge or a cozy cabin. Isn’t it amazing how much science is involved in something that seems so simple?

Table of Contents

Understanding Wood Structure Load: Essential Insights For Design

Wood can surprisingly hold a lot of weight! Understanding wood structure load is crucial for building safe, sturdy homes. This term refers to how much weight wooden beams and structures can support. It considers factors like wood type, size, and moisture content. Did you know that different woods can carry different loads? For example, oak is stronger than pine. Knowing this helps in making smart choices in construction, ensuring safety for everyone inside.

What is Wood Structure Load?

Definition and significance of wood structure load in construction.. Types of loads applied to wood structures: dead load, live load, and environmental loads..

Wood structure load refers to the weight and forces that buildings made of wood must support. It is important because it helps builders ensure the safety and stability of structures. There are three main types of loads:

- Dead Load: This is the weight of the building materials themselves, like walls and roofs.

- Live Load: This includes the weight of people, furniture, and other movable items inside the building.

- Environmental Load: This consists of forces from outside, such as wind or snow.

Factors Influencing Wood Structure Load Capacity

Material properties: wood species, moisture content, and treatment methods.. Structural design considerations: span, orientation, and crosssectional area..

Several factors affect how much weight wood structures can hold. First up is the wood species. Different types of wood have different strengths. Think of pine versus oak—one is soft, and the other is as strong as a superhero! Next, we have moisture content. Wood that’s too wet can bend or break, just like soggy bread. Treatment methods also matter. Preservatives can make wood as tough as nails.

Next, let’s look at design. The span between supports is crucial. A wider span needs stronger support, kind of like needing more friends to help lift a heavy box. The orientation of the wood can change how it carries weight too. Lastly, the cross-sectional area plays a role. Larger pieces can handle more weight. It’s like trying to lift a small marshmallow versus a massive pillow!

| Factor | Effect on Load Capacity |

|---|---|

| Wood Species | Stronger woods support more weight |

| Moisture Content | High moisture can weaken wood |

| Treatment Methods | Treatments enhance strength |

| Span | Longer spans need stronger support |

| Orientation | Placement affects strength |

| Cross-Sectional Area | Larger area increases load capacity |

Calculating Wood Structure Loads

Stepbystep guide on calculating dead loads and live loads.. Importance of load combination in structural engineering..

To calculate wood structure loads, follow these steps for dead and live loads:

- Dead Loads: Measure the weight of permanent fixtures like walls and roofs.

- Live Loads: Estimate the weight of people and furniture that move.

Load combinations are vital in structural engineering. They ensure structures can handle different weight scenarios safely. This prevents problems like failure under excess weight. Remember, safety first!

What are dead loads and live loads?

Dead loads are permanent weights from things like walls. Live loads are temporary weights like people or furniture that can change.

Common Applications of Wood Structures and Associated Loads

Residential buildings: framing, flooring, and roofing considerations.. Commercial and industrial uses: warehouses, bridges, and outdoor structures..

Wood is often used in many buildings. In homes, wood is great for framing, flooring, and roofing. It keeps things strong and comfy. In commercial settings, like warehouses and bridges, wood structures work well too. They can hold a lot of weight and provide space for activities. Just think of wood as the superhero of building materials—strong, reliable, and a little bit funny when it creaks! Here’s a quick comparison:

| Application | Common Uses |

|---|---|

| Residential Buildings | Framing, Flooring, Roofing |

| Commercial & Industrial | Warehouses, Bridges, Outdoor Structures |

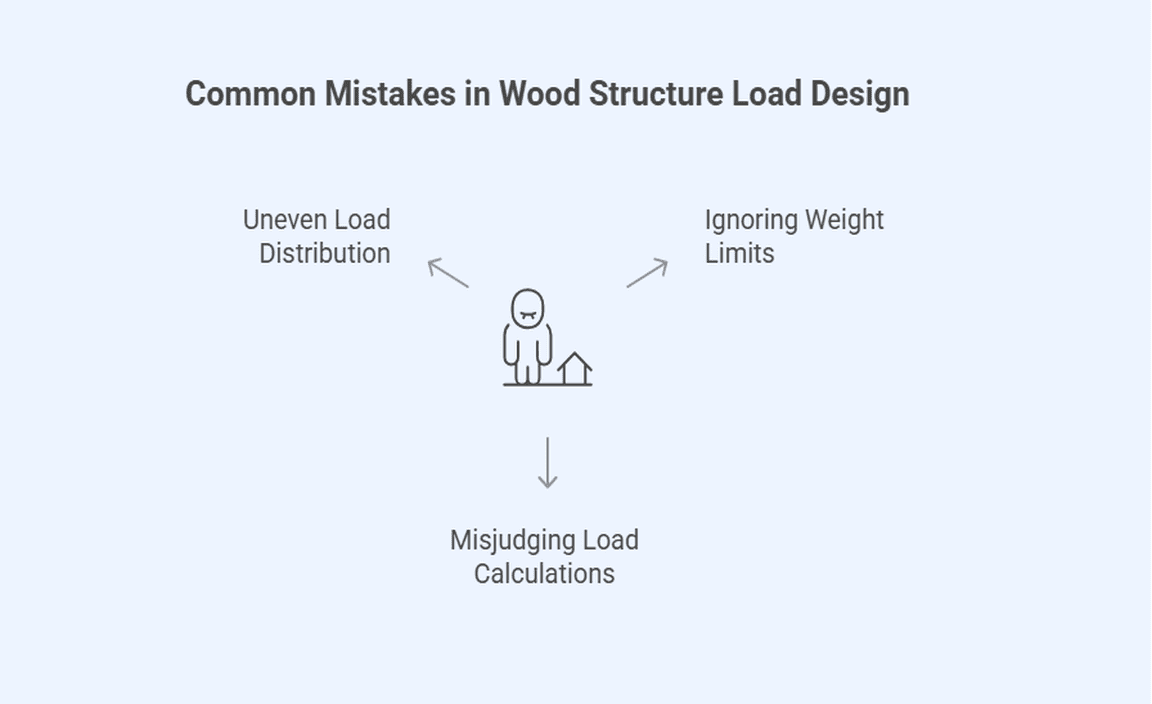

Common Mistakes in Wood Structure Load Design

Misunderstandings of load calculations and material limitations.. Consequences of improper load distribution and structural failure..

Many people make mistakes in wood structure load design. They often misunderstand how to calculate loads. Some think any wood can handle any weight. This is not true. Each wood type has limits. Misusing materials can cause serious problems.

If loads are not distributed evenly, the structure may fail. It can lead to dangerous situations. Builders should always follow proper guidelines.

- Ignore the weight limits of materials

- Misjudge load calculations

- Fail to distribute loads evenly

What are the common mistakes in wood structure load design?

Common mistakes include misunderstanding load calculations and material limits, and improper load distribution can lead to structural failures.

Innovative Solutions for Wood Structure Loading Challenges

New materials and technologies for enhancing load capacity.. Design strategies for optimizing performance under various load conditions..

Building with wood is not just about logs and boards anymore. New materials and technologies help make wood structures stronger. For example, engineers are using cross-laminated timber for better load support. Special design strategies make sure these wood structures can handle heavy loads safely.

- Lightweight composites can enhance strength without extra weight.

- Smart design can improve stability under pressure, like using trusses.

- 3D modeling helps predict how wood will perform in real life.

What are some innovative materials and technologies for wood structure loading?

Cross-laminated timber and lightweight composites are leading the way in enhancing wood structure load capacity.

Case Studies: Successful Wood Structure Load Implementations

Analysis of notable projects that successfully managed wood structure loads.. Lessons learned and best practices from realworld examples..

Several projects show how to manage wood structure loads well. For instance, a school built from wood handled weight impressively. They used sturdy beams and smart designs to create strong walls. Another example includes a community center that stayed safe during storms. They chose materials that are light but tough.

From these successes, we learn:

- Design matters a lot.

- Using the right materials makes a difference.

- Building strong foundations is key.

These examples guide future projects in using wood wisely.

What can we learn from these projects?

We can see the power of smart design, strong materials, and solid foundations. This means each project can be safer and last longer.

Future Trends in Wood Structure Load Management

Emerging technologies impacting wood load design and construction practices.. Sustainability concerns and the role of engineered wood products..

New technologies are shaking up how we handle wood structure loads. From smart sensors that monitor weight in real-time to 3D printing for custom designs, change is everywhere. These innovations not only make construction easier but also safer. Plus, with more folks caring about our planet, engineered wood products are becoming a favorite. They’re strong, eco-friendly, and help reduce waste. It’s like giving Mother Nature a high-five with every beam and board!

| Technology | Impact on Wood Load Design |

|---|---|

| Smart Sensors | Real-time load monitoring |

| 3D Printing | Custom and efficient designs |

| Engineered Wood Products | Eco-friendly and durable |

Conclusion

In conclusion, understanding wood structure load is important for building safe and strong structures. We learned that wood can support weight but has limits. You should always check load specifications when designing with wood. This knowledge helps prevent accidents and ensures durability. For more information, consider reading about structural engineering or wood properties. Let’s build safely and smartly!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Wood Structure Load:

Sure! Here are some questions about wood structure load. 1. What helps wood hold weight? Strong wood fibers help support heavy things. 2. Why does wood bend? When it carries too much weight, it can bend or break. 3. What types of wood are strongest? Hardwoods like oak are usually stronger than softwoods like pine. 4. How do builders know how much weight wood can hold? Builders test wood and check its size to see its strength. 5. Why is it important to use the right wood? Using the wrong type of wood can cause buildings to collapse.

Sure! Please provide the question you’d like me to answer.

What Factors Influence The Load-Bearing Capacity Of Wood Beams In Structural Applications?

The load-bearing capacity of wood beams depends on a few important things. First, the type of wood matters. Some woods are stronger than others. Second, the size and shape of the beam can change how much weight it can hold. Lastly, how the beam is used in a building, like its support points, also affects its strength.

How Do Different Species Of Wood Compare In Terms Of Strength And Load Resistance?

Different types of wood are strong in different ways. For example, oak is very sturdy and holds up heavy things well. Maple is also strong but is a bit lighter. Softwoods, like pine, are not as strong but are easier to work with. So, when building something heavy, you want to choose a strong wood, like oak.

What Is The Importance Of Moisture Content In Wood When Considering Structural Load Capacity?

Moisture content in wood is super important. When wood is wet, it can be weaker and bend more. This means it can’t hold heavy loads as well. If wood dries out too much, it may crack. So, we need to check the moisture to make sure wood is strong enough for building things.

How Does The Design Of Wooden Structures Account For Dynamic Loads, Such As Wind Or Seismic Activity?

When engineers design wooden buildings, they think about strong winds and earthquakes. They make sure the wood can bend without breaking. They also use special shapes and connections to help the building move safely. This way, when the wind blows or the ground shakes, the building stays standing and safe for us.

What Are Common Methods Used To Evaluate Or Test The Load Capacities Of Wood Components In Construction?

To test how much weight wood can hold, we can use a few methods. First, we can put weights on the wood and see how much it bends or breaks. This shows us its strength. We can also look at the wood’s plans and grades, which tell us how strong it is supposed to be. Lastly, we might use special machines to push or pull on the wood, measuring how much force it can take.

Resource:

Understanding Load Types in Engineering: https://www.engineeringtoolbox.com/imposed-loads-d_1313.html

Wood Strength Comparison Charts: https://www.wood-database.com/wood-articles/wood-strength-comparison/

Moisture Content & Wood Performance: https://www.fs.usda.gov/treesearch/pubs/22354

Cross-Laminated Timber Innovations: https://www.thinkwood.com/products-solutions/cross-laminated-timber