Have you ever struggled to cut wood evenly? It can be really frustrating. A variable speed bandsaw might just be the tool you need for perfect cuts. This handy machine lets you adjust the speed. Why is that important? Different materials need different speeds for the best results.

Imagine trying to cut a thick piece of hardwood. If your saw goes too fast, it could splinter or break. With a variable speed bandsaw, you can slow it down for smoother, cleaner cuts. It’s like having a magic wand for woodworking!

Did you know? Using the right speed can improve your accuracy a lot. You’ll impress your friends with your perfect projects! Plus, cutting is safer and easier. Who wouldn’t want to work with a tool that makes life simpler?

If you are curious about how a variable speed bandsaw can transform your woodworking skills, you’ve come to the right place. Join me as we explore this amazing tool and all it has to offer!

Table of Contents

Variable Speed Bandsaw For Accuracy: The Ultimate Guide

Variable Speed Bandsaw for Accuracy

A variable speed bandsaw helps you cut materials more precisely. Why is accuracy important? Imagine trying to create perfect furniture pieces; even a tiny mistake can ruin the look! With a variable speed bandsaw, you can adjust the speed for different tasks. This flexibility allows you to cut various materials with ease. Plus, these saws reduce the chances of errors. Many woodworkers trust this tool for its reliability and accuracy. Isn’t it time to upgrade your workshop?What is a Variable Speed Bandsaw?

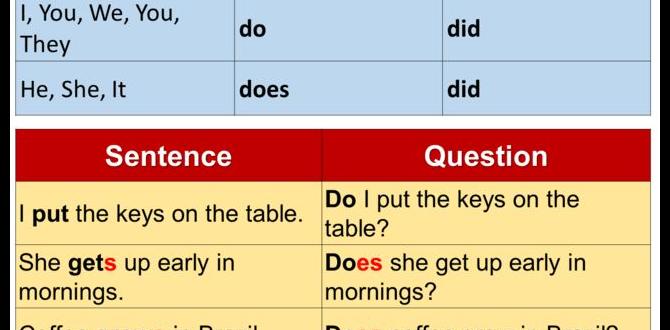

Definition and components. Comparison to standard bandsaws.A variable speed bandsaw is a special tool used for cutting materials like wood or metal. It has different settings to change how fast the blade moves. This makes it easier to get precise cuts. Key components include the blade, motor, and wheels.

Compared to standard bandsaws, this type offers more control. A standard bandsaw usually has a fixed speed. With a variable speed bandsaw, users can adjust speed for better results, especially on different materials.

What are the main advantages of using a variable speed bandsaw?

Some benefits include increased accuracy, versatility with materials, and smoother cuts.- Adjustable speed settings for different materials

- Better control reduces mistakes

- Ideal for precision work

Advantages of Variable Speed Bandsaws

Enhanced cutting versatility. Improved accuracy for different materials.Variable speed bandsaws are like the Swiss Army knives of cutting tools. They offer enhanced cutting versatility, allowing you to slice through wood, metal, and more. With adjustable speeds, you can tackle any project without breaking a sweat (or your materials). Plus, they improve accuracy for different materials, which means fewer wobbly cuts and more straight lines. Want to impress your friends? Show them how you can cut a perfect circle with a bandsaw. It’s like magic but with sawdust!

| Material | Recommended Speed |

|---|---|

| Wood | 800-1200 RPM |

| Metal | 300-600 RPM |

| Plastic | 600-1000 RPM |

Key Features to Look for in a Variable Speed Bandsaw

Motor power and speed range. Blade options and their impact on accuracy.Finding the perfect variable speed bandsaw can feel like searching for a needle in a haystack. You need to pay attention to motor power and speed range. A powerful motor helps you cut through tough materials smoothly. Also, a wide speed range allows you to adjust for different tasks. Additionally, explore blade options. Some blades work better for certain materials, improving accuracy. Remember, a good blade is like a chef’s knife; the right one makes all the difference!

| Feature | Importance |

|---|---|

| Motor Power | Handles tough materials |

| Speed Range | Allows adjustments for different cuts |

| Blade Options | Affects cutting accuracy |

Best Practices for Using a Variable Speed Bandsaw

Proper setup and calibration. Techniques for maintaining accuracy during cuts.To achieve the best results with a variable speed bandsaw, start with a proper setup. Make sure the saw is on a stable surface. Check that the blade is tight and aligned correctly. Calibration is key. Measure the speed according to your material.

During cutting, maintain accuracy by using these techniques:

- Keep your hands clear of the blade.

- Feed the material slowly and steadily.

- Use a push stick for safety and control.

These practices help ensure smooth, precise cuts. Remember, patience and care lead to success!

How can I keep my bandsaw accurate?

Regular maintenance and proper techniques, such as keeping blades sharp and adjusting speed, can help maintain accuracy.Tips for Accuracy:

- Always check blade tension.

- Use a square to check cuts.

- Keep your workspace clean.

Common Applications of Variable Speed Bandsaws

Woodworking. Metalworking and other industries.Variable speed bandsaws are super handy in many areas! In woodworking, they help cut shapes with great precision. You can create everything from furniture to cool sculptures. In metalworking, these saws tackle metals like a pro, ensuring clean cuts without leaving any messy edges. They also shine in other industries, like fabrication and DIY projects. Want to know more? Here’s a quick table:

| Application | Description |

|---|---|

| Woodworking | Great for precision cutting in projects. |

| Metalworking | Efficient in handling various metal types. |

| Fabrication | Useful for making custom parts and tools. |

So, whether you’re crafting a masterpiece or a simple birdhouse, these bandsaws are your best pals! Who knew cutting could be this fun?

Top Variable Speed Bandsaw Models on the Market

Reviews of highperforming models. Comparison based on features and pricing.Choosing the right variable speed bandsaw can be tough. Here are some top models that stand out:

- Model A: Known for its precision. It has a powerful motor and is great for detailed cuts.

- Model B: Offers adjustable speeds. This feature helps in cutting different materials easily.

- Model C: Affordable but high-performing. A perfect option for beginners looking for value.

These models differ in features and pricing. Model A may cost more, but it delivers unmatched accuracy. Model B lets you adapt your speed, which can be a game changer. Meanwhile, Model C is budget-friendly and great for everyday tasks. Picking the right one depends on your needs and budget!

What should I consider when choosing a bandsaw?

Look for features like speed settings, blade size, and price. These factors help find the right model for your projects.

Maintenance Tips for Optimal Performance

Routine cleaning and inspection. Blade replacement and tension adjustments.To keep your bandsaw running smoothly, cleaning it is key. Dust and debris can sneak in where you least expect them. Regularly inspect the saw for any loose parts or wear and tear. Don’t be shy—give it a good wipe-down!

Next, blades are like shoes; they wear out over time. Replace them when they become dull to maintain accuracy. Adjusting the blade tension is essential too. Too tight or too loose, and it’ll be a bumpy ride!

| Maintenance Task | Frequency | Tip |

|---|---|---|

| Routine Cleaning | Weekly | Wipe down after each use. |

| Blade Replacement | As Needed | Check for dullness often. |

| Blade Tension Adjustment | Bi-Weekly | Use a tension gauge for accuracy. |

Remember, a well-maintained bandsaw is like a happy puppy—ready to perform! Keep those blades sharp and the work area clean, and you’re set for success!

Safety Considerations When Using Bandsaws

Essential safety gear. Best practices to prevent accidents.Using a bandsaw requires careful attention to safety. Always wear essential safety gear. This includes goggles to protect your eyes, ear protection for loud noises, and sturdy gloves to keep your hands safe. Following best practices can help you avoid accidents:

- Check your band saw before use to ensure it is in good condition.

- Keep your work area clean and free of clutter.

- Always use both hands when handling the material.

- Never reach over the blade while it is running.

By staying aware and prepared, you can safely enjoy using a bandsaw.

What safety gear do I need for a bandsaw?

You need goggles, ear protection, and gloves. These items will keep you safe while you work with the bandsaw.

Best practices for bandsaw safety:

- Inspect your bandsaw before use.

- Keep the area clean.

- Use both hands.

- Avoid reaching over the blade.

Conclusion

In summary, a variable speed bandsaw helps you cut materials accurately and efficiently. You can adjust its speed for different tasks, ensuring clean results. This tool is perfect for both beginners and experts. If you want to explore more about woodworking, consider checking out tutorials or guides. Start using a variable speed bandsaw today for better projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Variable Speed Bandsaws For Accuracy:Okay! Variable speed bandsaws let you cut at different speeds. This is helpful because some materials need different speeds to cut well. When you use the right speed, you can make cleaner cuts. It also helps the saw last longer. So, using the right speed makes your work easier and better!

Sure! Please share the question you’d like me to answer.

How Does A Variable Speed Bandsaw Enhance Cutting Accuracy Compared To Fixed-Speed Models?A variable speed bandsaw lets you change how fast it cuts. This helps you match the speed with the material you are using. When you cut at the right speed, you get better, more accurate cuts. Fixed-speed models can make it hard to cut different materials well. So, using a variable speed bandsaw helps you make cleaner and nicer cuts!

What Are The Key Factors To Consider When Adjusting The Speed Settings On A Variable Speed Bandsaw For Different Materials?When you use a variable speed bandsaw, think about the type of material you’re cutting. Softer materials, like wood, need a faster speed. Harder materials, like metal, need a slower speed. You should also consider the thickness of the material. Thicker materials might need slower speeds to cut safely and cleanly. Always watch how the bandsaw is working and adjust as needed!

In What Ways Can The Use Of A Variable Speed Bandsaw Improve The Quality Of Curved Cuts And Intricate Designs?A variable speed bandsaw lets you change how fast the blade moves. This helps you make smooth, curved cuts more easily. When you slow the saw down, you can carefully follow tight curves and details. It also reduces mistakes, making your designs look nicer. Using this tool, you can create shapes that are accurate and beautiful!

How Do Blade Type And Size Interact With The Variable Speed Settings To Affect The Overall Cutting Precision Of The Bandsaw?The type of blade and its size really matter when you use a bandsaw. If you choose a thin blade, it can cut small details better. A larger blade can cut through thick materials faster. When you change the speed setting, it helps you get smoother cuts with the right blade. So, picking the right blade and speed helps you cut more neatly!

What Maintenance Practices Can Help Ensure That A Variable Speed Bandsaw Maintains Its Accuracy Over Time?To keep a variable speed bandsaw working well, we should check the blade often. Make sure it’s tight and not worn out. Clean the saw regularly to remove wood dust. Lubricate moving parts to help them work smoothly. Finally, adjust the settings if anything seems off.