Have you ever tried to use a nailer, only to find it leaking air? It can be frustrating, right? Understanding how to troubleshoot nailer pressure leaks is essential for anyone who works with tools.

Imagine starting a project, excited to build something amazing. Suddenly, your nailer stops working properly. What do you do? Most people panic or give up. But the truth is, fixing that pressure leak can be quite simple!

Did you know that a small problem can cause big headaches? Just a tiny leak can slow down your work. By learning to spot and solve these issues, you’ll save time and effort.

In this article, we will explore easy steps to troubleshoot nailer pressure leaks. With the right tips, you’ll feel like a pro, ready to tackle any project. Let’s get started and make your nailer work like new!

Table of Contents

Troubleshooting Nailer Pressure Leak: Common Causes And Fixes

Troubleshooting Nailer Pressure Leak

Discovering a pressure leak in your nailer can be frustrating, especially during a project. First, check for loose connections or damaged hoses. Use soapy water to find bubbles that indicate leaks. Regular maintenance can prevent future issues. Did you know a small leak can significantly decrease performance? By learning these simple steps, you can keep your nailer running smoothly and avoid delays. It’s all about being proactive to ensure your tools work efficiently!Understanding Nailer Pressure Systems

Explanation of nailer pressure systems and their components. Importance of maintaining proper pressure levels for optimal performance.Nailer pressure systems help tools work well. These systems include several important parts like the compressor, hoses, and fittings. Each part must work together to create the right pressure. Keeping the right pressure is key for your nailer to function properly. If the pressure is too low or too high, it can cause problems or damage.

- Compressor: Generates air pressure.

- Hoses: Carry air to the tool.

- Fittings: Connect parts securely.

Regular checks will keep your nailer running smoothly and make jobs easier.

What happens if nailer pressure is too low?

If nailer pressure is too low, nails might not drive in properly.

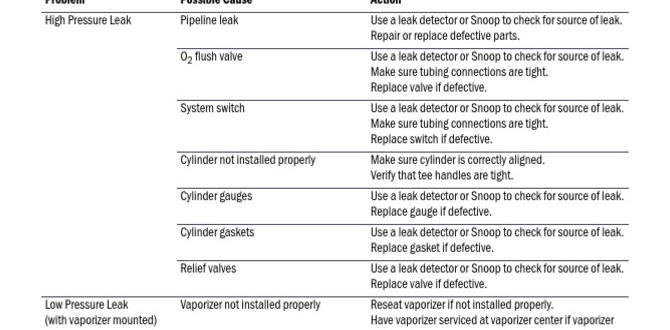

Common Causes of Pressure Leaks in Nailers

Identification of typical issues leading to pressure loss. Discussion of wear and tear on seals and hoses.Many things can cause pressure leaks in nailers. One big issue is wear and tear on seals and hoses. Over time, they can crack or break, leading to loss of pressure. Another common problem is dirt or debris clogging the parts. This makes it hard for the nailer to work properly. Regular checks can help you catch these issues early.

- Worn seals or hoses

- Dirt or debris buildup

- Loose connections

What are common causes of pressure leaks in nailers?

Common causes include worn seals and hoses, dirt buildup, and loose connections. These factors can all contribute to pressure loss.

Diagnosing a Pressure Leak

Stepbystep process for checking nailer pressure. Tools and techniques for detecting leaks effectively.To find a pressure leak, follow these steps. First, check all connections and fittings. Look for any cracks or broken parts. Second, use soap and water to check for bubbles. Apply it to suspected areas. If you see bubbles, you have found the leak. Lastly, inspect the air hose for damage. Replace any faulty parts. This method is effective and simple.

- Use a pressure gauge to check correct PSI.

- Listen for hissing sounds while testing.

- Ensure the nailer is off before inspecting.

How can I find leaks in my nailer?

To find leaks in your nailer, check hoses, connections, and look for bubbles with soapy water.

How to Fix Nailer Pressure Leaks

Detailed repair methods for specific leak sources. Replacement parts and maintenance practices to prevent future leaks.Finding pressure leaks in your nailer can be as frustrating as trying to find a lost sock! Start by inspecting the hose and fittings. Look for cracks or loose connections. If you see any damage, replace the faulty part. Leaks can also come from the nailer itself. Check the O-rings and seals. If they’re worn out, swapping them out should help. To prevent future leaks, keep your tools clean and lubricated. Regular maintenance is key!

| Leak Source | Repair Method | Replacement Parts |

|---|---|---|

| Hose | Check for cracks; tighten connections | New hose |

| O-rings | Inspect and replace if worn | Replacement O-ring kit |

| Fittings | Ensure tight fittings | New fittings |

Preventive Measures for Nailer Pressure Issues

Best practices for nailer maintenance and care. Routine checks and maintenance schedules.Taking care of your nailer can save you from unexpected pressure leaks. Regular check-ups are important, kind of like visiting the doctor but without the waiting room! Always clean your nailer after use to keep it healthy. Set up a routine, perhaps every two weeks, to inspect for any wear and tear. If you see a loose hose or a dirty air filter, fix it quickly. Remember these habits can make your nailer last longer and keep it working like new!

| Maintenance Task | Frequency |

|---|---|

| Clean nailer after each use | Every use |

| Inspect hose for leaks | Every two weeks |

| Check air filter | Monthly |

| Replace worn parts | As needed |

Following routines like these keeps your nailer in tip-top shape, preventing those pesky leaks before they even start!

When to Seek Professional Help

Signs that indicate the need for professional servicing. Benefits of professional repairs versus DIY solutions.It’s often tricky to know when to call in the pros. If your nailer starts making weird noises or leaks pressure like a faucet, it’s time for help. Look for signs like inconsistent firing or loss of power. These hints can save you time and frustration. Professional repairs often provide lasting solutions, while DIY fixes are like using duct tape on a boat—only good until you hit rough water!

| Signs to Seek Help | Benefits of Professional Repairs |

|---|---|

| Weird noises | Longer-lasting fixes |

| Pressure leaks | Expert knowledge |

| Inconsistent nails | Warranty coverage |

Don’t wait until your nailer has a complete meltdown! Get it checked before it decides to take a permanent break. Remember, confirming with a pro can save you hassle and give you peace of mind.

Conclusion

In conclusion, fixing a nailer pressure leak is important for safe and effective work. First, check the air hoses for damage. Then, examine connections and seals. Remember to always follow the manufacturer’s guidelines. By taking these simple steps, you can ensure your nailer works well. For more tips, consider reading our detailed guides or watch helpful videos online.FAQs

What Are The Common Causes Of Pressure Leaks In Nailers, And How Can They Be Identified?Common causes of pressure leaks in nailers include damaged hoses, loose connections, and worn-out seals. You can spot a leak by listening for hissing sounds or feeling air escaping. Check the hoses and connections to see if they are secure. If you see any cracks or tears, that might be the problem. Regularly inspecting your nailer helps keep it working well.

How Can I Check For Air Leaks In My Nailer’S Hoses And Fittings?You can check for air leaks by looking at the hoses and fittings closely. First, turn on your nailer and listen for hissing sounds. If you hear air escaping, that’s a leak. You can also spray soapy water on the hoses and connections. If you see bubbles forming, that means there’s a leak.

What Steps Should I Take To Troubleshoot And Repair A Nailer That Is Not Maintaining Proper Pressure?First, check the air compressor. Make sure it is full and working. Next, look for any leaks in the hoses or connections. You can use soap and water to find bubbles, which show leaks. If everything seems fine, clean the nailer and change the filter if it has one. Finally, check the manual for more help on repairs.

Are There Specific Maintenance Practices That Can Help Prevent Pressure Leaks In Nailers?Yes, we can do things to stop pressure leaks in nailers. First, check the hose often for cracks. Then, keep the nailer clean and free of dust. Next, oil it regularly as the instructions say. Finally, make sure all parts are tightly connected. Doing these steps helps keep your nailer working well!

What Safety Precautions Should I Consider When Diagnosing Or Repairing A Nailer’S Pressure System?When working on a nailer’s pressure system, you should always wear safety goggles to protect your eyes. Make sure to unplug the tool or remove the battery to avoid accidental starts. Check for air leaks and don’t point the nailer at anyone, even when it’s off. Keep your work area clear to avoid trips and falls. Finally, read the manual to understand how the nailer works safely.