Bent nails happen, but they don’t have to stop your project. Learn easy fixes for common nail gun issues, from adjusting depth to clearing jams. Get your DIY projects back on track with simple troubleshooting steps for your finish nailer.

So you’re working on a project, feeling good, and then… thwack… followed by that dreaded crunch that means a bent nail. We’ve all been there! It’s one of those little hiccups that can really test your patience when you’re just trying to get a job done. But don’t let a few bent nails derail your DIY dreams. Figuring out why they bend and how to fix it is a super useful skill for anyone who uses a nail gun.

This guide is here to help you tackle bent nails head-on. We’ll break down the most common reasons why nails bend in your finish nailer and give you simple, step-by-step solutions. You’ll learn how to adjust your tool, prepare your materials, and handle those frustrating jams so you can get back to building with confidence. Let’s dive in and turn those bent nail blues into your next DIY success story!

Table of Contents

Why Do Nails Bend in Finish Nailers? Common Culprits

It feels like a small thing, but a bent nail can throw a wrench into your workflow. Understanding the root causes is the first step to solving the problem. Most of the time, it’s not the nail’s fault! It’s usually a combination of how the nail gun is set up, the materials you’re working with, or even the nails themselves. Let’s explore the usual suspects:

1. Incorrect Depth Setting

One of the most frequent reasons for bent nails is how deep the nail gun is set. If the depth is set too high, the nail will be driven with too much force for the material. This forceful impact can cause the nail to deflect, especially if it hits a knot or a harder section of wood. The nail essentially gets pushed sideways rather than straight in.

2. Hitting Knots or Hardwood Grain

Wood isn’t always uniform. You might encounter knots, mineral streaks, or dense areas in hardwood. When your nail encounters these tough spots, it can bend. The nail doesn’t have enough force or the right angle to penetrate cleanly, so it deflects. This is less about a tool problem and more about the unpredictable nature of wood itself.

3. Low Air Pressure (for Pneumatic Nailers)

For pneumatic nailers, air pressure is the engine that drives the nail. If the air pressure is too low, the nail won’t have enough power to fully penetrate the wood. It might get halfway in and then bend as it struggles against the material. It’s like trying to push a nail with a gentle tap instead of a solid hammer blow.

4. Nail Gun Not Placed Flat Against the Surface

The angle at which you hold the nail gun matters. If the nose of the nailer isn’t flat and flush against the workpiece when you fire, the nail can go in at an angle. This off-kilter entry is a prime candidate for causing the nail to bend as it meets resistance. A stable, perpendicular placement is key for a straight shot.

5. Using the Wrong Size or Type of Nails

Nail guns are designed for specific nail sizes and types. Using nails that are too long, too thick, or not designed for your specific nailer can lead to bending. For example, trying to drive a finishing nail meant for a 16-gauge nailer with a 15-gauge nailer could cause issues, as the drive mechanism isn’t perfectly aligned with the nail. Always check your nailer’s manual for compatible fasteners.

6. Obstructions in the Nail Path

Inside the nail gun, there’s a channel the nails travel through before being fired. If there’s a bit of debris, a previously jammed nail fragment, or even a burr on the inside of the gun, it can warp the nail as it’s propelled forward. This usually results in a bent nail and a jam.

7. Worn or Damaged Nailer Components

Over time, parts of your nail gun can wear out or get damaged. A bent driver blade (the part that strikes the nail head) or a misaligned nose piece can directly cause nails to bend upon firing. If you’ve tried everything else and are still seeing bent nails, it might be time to inspect your tool for wear and tear.

Essential Tools and Materials for Fixing Bent Nails

Don’t worry, you don’t need a whole new workshop to deal with bent nails. Most of the time, a few basic tools you likely already have are all you need. Having these ready will make troubleshooting and fixing the issue much smoother.

Here’s what you should have on hand:

<strong>Safety Glasses:</strong> This is non-negotiable! Always protect your eyes from flying debris or nail fragments.

<strong>Pliers (Needle-nose or standard):</strong> Great for gripping and pulling out bent nails from the wood.

<strong>Hammer:</strong> For gently tapping in nails that are only slightly bent or for persuasion on stubborn ones.

<strong>Wooden Dowel or Shim:</strong> Can be useful for nudging a nail that’s mostly in but slightly off-angle.

<strong>Screwdriver (Flathead):</strong> Can sometimes be used to lever a bent nail out.

<strong>Air Pressure Regulator (for Pneumatic Nailers):</strong> Essential for fine-tuning the air pressure.

<strong>Spare Nails (Correct Size and Type):</strong> So you can test your fixes or replace the problematic ones.

<strong>Wood Filler or Putty:</strong> For patching any holes left by failed nail attempts.

<strong>Work Gloves:</strong> To protect your hands when removing stubborn nails.

Step-by-Step Guide: Troubleshooting Bent Nails in Your Finish Nailer

Now that we know why nails bend, let’s get to fixing them! Follow these steps to diagnose and solve your bent nail problems.

Step 1: Prioritize Safety First!

Before you touch anything on your nail gun, always disconnect it from the power source. For pneumatic nailers, this means unplugging the air hose. For electric or battery-powered nailers, remove the battery or unplug it from the wall. Safety is paramount when working with any power tool.

Step 2: Examine the Bent Nail

Take a close look at how the nail is bent and where it’s located.

<strong>Partially driven:</strong> If the nail is sticking out but bent, you can usually grip it with pliers and pull it straight out. Sometimes, a slight tap with a hammer on the underside of the nail head can help loosen it before pulling.

<strong>Deeply driven but bent:</strong> If the nail is mostly in the wood but bent, you might need to use a flathead screwdriver or a shim to gently pry under the nail head and lever it out. Be careful not to damage the surrounding wood.

<strong>Completely stuck/jammed:</strong> This usually indicates a more serious issue that might require disassembling part of the nail gun.

Step 3: Check Your Nail Gun’s Air Pressure (Pneumatic Nailers)

If you’re using a pneumatic finish nailer, the air pressure is a critical setting.

1. <strong>Consult Your Nailer’s Manual:</strong> Find the recommended operating pressure range for your specific model. Generally, finish nailers operate between 70-120 PSI (Pounds per Square Inch).

2. <strong>Adjust the Regulator:</strong> Connect your air hose to the compressor and nailer. Use the regulator on your compressor or an inline regulator to set the pressure.

3. <strong>Test Fire:</strong> Start at the lower end of the recommended range (e.g., 70-80 PSI) and fire a nail into a scrap piece of your material.

4. <strong>Increase Gradually:</strong> If the nail doesn’t drive fully or bends, increase the pressure by 5-10 PSI at a time and test again. Avoid going above the maximum recommended pressure, as this can damage the tool and the wood, and even cause nails to mushroom or bend inconsistently.

Here’s a quick guide to typical pressure settings for different nail types:

<table>

<caption>Recommended Air Pressure Ranges for Pneumatic Nailers</caption>

<thead>

<tr>

<th>Nailer Type</th>

<th>Typical PSI Range</th>

<th>Notes</th>

</tr>

</thead>

<tbody>

<tr>

<td>Finish Nailer (15-16 Gauge)</td>

<td>70 – 120 PSI</td>

<td>Adjust based on wood hardness and nail length.</td>

</tr>

<tr>

<td>Brad Nailer (18 Gauge)</td>

<td>60 – 100 PSI</td>

<td>Generally runs lower than finish nailers.</td>

</tr>

<tr>

<td>Framing Nailer (2-3.5 Inch Nails)</td>

<td>90 – 120 PSI</td>

<td>Requires higher pressure for structural work.</td>

</tr>

</tbody>

</table>

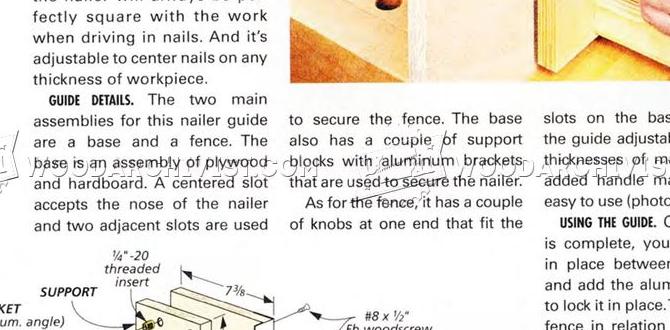

Step 4: Adjust the Depth of Drive Setting

Most finish nailers have an adjustable depth of drive. This controls how deep the nail head sits below the surface of the wood.

1. <strong>Locate the Adjustment Wheel/Knob:</strong> This is usually found near the nose of the nail gun. Consult your manual if you can’t find it.

2. <strong>Test on Scrap Material:</strong> Fire a nail into a piece of scrap lumber similar to your project material.

3. <strong>Adjust for Desired Depth:</strong>

<strong>Nail head proud (sticking out):</strong> Increase the depth of drive. This means the nail will be driven deeper.

<strong>Nail head too deep (countersunk too much):</strong> Decrease the depth of drive. This means the nail will be driven shallower.

4. <strong>Fine-tune:</strong> Make small adjustments and test fire again until the nail head sits just slightly below the surface of the wood, or flush, depending on your preference and the project. Often, a slight countersink is desired for trim work to allow for filling.

Step 5: Ensure Proper Nail Gun Placement

This is simple but incredibly important. Always place the nose of the nail gun flat and perpendicular to the surface of the wood at the point where you want to drive the nail.

<strong>Get it flush:</strong> Make sure the entire nose piece is in contact with the wood. No gaps!

<strong>Shoot straight:</strong> Aim to drive the nail straight into the wood, not at an angle.

<strong>Firm, but not crushing:</strong> Apply even pressure. You don’t need to lean on it hard, but ensure it’s stable.

Step 6: Inspect and Use the Correct Nails

Are you using the right nails for your nailer and your project?

<strong>Gauge and Length:</strong> Check your nailer’s manual for the recommended gauge (e.g., 15-gauge, 16-gauge) and length of nails it can handle.

<strong>Collation Type:</strong> Nails are collated (glued or papered) at different angles. Ensure you’re using the correct angle for your nailer (e.g., straight or 15-degree). Using the wrong collation angle can cause jams and bent nails.

<strong>Quality:</strong> Cheap or poorly manufactured nails can be brittle or misformed, leading to bends. Try a different brand if you suspect this is the issue.

<strong>Loading:</strong> Ensure nails are loaded correctly and feeding smoothly into the gun.

Step 7: Inspect for Internal Obstructions or Damage

If the above steps don’t solve the problem, it’s time to look inside the nail gun.

1. <strong>Disconnect Power:</strong> (We can’t stress this enough!)

2. <strong>Inspect the Nose Piece:</strong> Look for any damage, debris, or bent metal around the opening where the nails come out.

3. <strong>Open the Magazine/Feeder:</strong> Many nailers allow you to open the magazine to access the driver blade and the nail track. Look for any stuck nail fragments, plastic debris from the collation, or burrs. A small pick or needle-nose pliers might be needed to remove debris.

4. <strong>Check the Driver Blade:</strong> This is the metal rod that strikes the nail head. If it’s bent, it will likely cause bent nails. If you see damage, it might be time for repair or replacement. The Occupational Safety and Health Administration (OSHA) has standards for power tool safety, including the importance of well-maintained equipment.

Step 8: Dealing with Stubborn Bent Nails in Wood

Sometimes, even after fixing the gun, you’ve got a bent nail stuck in your workpiece. Here’s how to extract it:

1. <strong>For partially driven nails:</strong> Grip the nail head firmly with pliers and pull straight out. Wiggle it gently if needed.

2. <strong>For deeply driven nails:</strong>

<strong>Leverage:</strong> Place a thin piece of wood or a putty knife under the nail head to protect the wood surface. Then, use your pliers or a flathead screwdriver to carefully lever the nail head upwards, gradually pulling it out.

<strong>Tap and Pull:</strong> Sometimes, gently tapping the nail head with a hammer can loosen its grip. Then try to pull it out.

<strong>Drill it Out (Last Resort):</strong> If a nail is extremely stubborn, you can very carefully drill it out with a drill bit slightly larger than the nail shaft. This will destroy the nail and leave a hole you’ll need to fill. Always drill slowly and carefully.

Step 9: Patching and Repairing the Wood

Once the bent nail is removed, you’ll likely have a hole or some minor damage to the wood.

<strong>Small Holes:</strong> Use a small amount of wood filler or putty. Apply it with a putty knife, slightly overfilling the hole. Once it dries, sand it smooth to match the surrounding wood.

<strong>Slight Surface Damage:</strong> If the wood surface is slightly dented or scratched from prying, light sanding should smooth it out. Consider applying a touch-up stain or paint to match.

Preventing Future Bent Nails: Proactive Tips

Fixing bent nails is great, but preventing them is even better! A few proactive habits can save you a lot of frustration.

Know Your Tool: Read your nailer’s manual thoroughly. Understand its settings and limitations.

Material Matters: Always consider the wood you’re working with. Softer woods require less pressure and might deflect less. Hardwoods or engineered materials like plywood might need recalibration. For extremely hard materials, consider switching to a more powerful nailer or pre-drilling pilot holes (though this is less common for finish nailers).

Regular Maintenance: Keep your nailer clean. Regularly check for debris in the magazine and nose. Periodically apply a drop of pneumatic tool oil if your tool requires it.

Test Fire: Always do a test fire on a scrap piece of your material before starting on the actual