Imagine you have a toy that can lift heavy things. But what if it breaks because it’s lifting too much? That’s where the screw load limit comes in. It tells us how much weight a screw can hold safely.

Many people don’t think about screws outside of their use in toys or furniture. However, these little pieces are vital in everything from bridges to roller coasters! Did you know that using the wrong screw could lead to dangerous situations?

Understanding the screw load limit can help you make smart choices. It ensures a project stays safe and sturdy. So, the next time you see a screw, remember its hidden power. Ask yourself, “How much can this tiny screw actually carry?”

Table of Contents

Understanding Screw Load Limit: Importance And Specifications

Understanding the **screw load limit** is important for safety and performance. This limit shows the maximum weight a screw can handle before it fails. Did you know that using the wrong screw can lead to accidents? Imagine hanging a heavy frame only to have it crash down! Knowing the load limit helps you choose the right screws for different tasks. Whether you’re building a treehouse or fixing furniture, always check the screw load limit for strong and safe results.

Understanding Screw Load Limit

Definition of screw load limit and its importance in engineering.. Factors that influence the screw load limit, including material properties and design..

The screw load limit tells us how much weight a screw can handle without breaking. Imagine it like a superhero’s strength! Knowing this limit is key in engineering. It helps keep buildings and machines safe. Factors like material strength and design play a big role. For example, a steel screw holds much more than a plastic one. If a screw gets overloaded, it could snap. That’s why understanding these limits is crucial.

| Factor | Influence on Screw Load Limit |

|---|---|

| Material | Stronger materials allow higher load limits. |

| Design | A good design helps distribute weight evenly. |

| Thread Count | More threads can increase grip and strength. |

Calculating Screw Load Limit

Stepbystep guide on how to calculate the load limit for a specific screw.. Common formulas and principles related to screw load limit calculations..

To find the screw load limit, start with the diameter and type of screw. Calculate the area using the formula: Area = π x (diameter/2)2. Then, apply the formula: Load Limit = Area x Material Strength. Remember, materials have different strengths, so check for steel, plastic, or others. Always consider safety, and add a factor of safety to your calculation. This ensures the screw won’t break.

What is the best way to calculate the load limit for a screw?

The best way to calculate the screw load limit includes these steps:

- Measure the screw diameter.

- Calculate the area.

- Find the material strength.

- Use the load limit formula.

Factors Affecting Screw Load Limit

Detailed analysis of environmental factors (temperature, humidity) impacting load limits.. Discussion on installation techniques and their significance on load capacities..

Many things can change how much load a screw can handle. Temperature plays a big role. Hot weather can weaken screws, while cold can make them brittle. Another factor is humidity. If it’s very moist, screws can rust, which also lowers their strength. Additionally, how screws are installed matters. Using proper techniques ensures a better grip and load capacity. If not installed correctly, screws may slip or break.

What affects screw load limit?

Several things affect the screw load limit, like weather and installation. Temperature and humidity can change how well screws work.

Key Factors:

- Temperature variations

- Humidity levels

- Installation techniques

Just like superheroes, screws need the right conditions to be strong! Keeping them safe from rust and using good techniques helps them in their tough jobs.

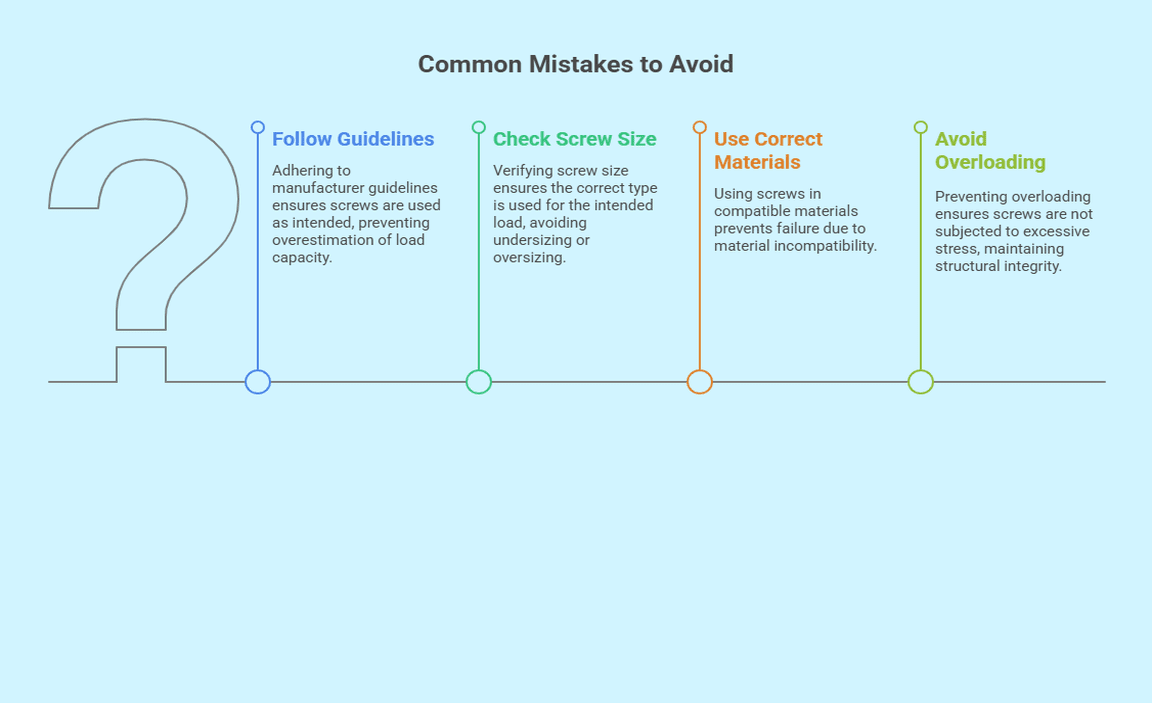

Common Mistakes to Avoid

List of errors engineers and builders make regarding screw load limits.. Tips for ensuring accurate load limits are adhered to in design and construction..

Many engineers and builders make common mistakes about screw load limits. They may overestimate what screws can hold. This can cause big problems in construction. Here are some frequent errors:

- Ignoring manufacturer guidelines

- Not checking screw size

- Using screws in the wrong materials

- Overloading screws

To avoid these mistakes, always follow guidelines. Double-check load limits and screw types. Use the right screws for your project. This will help keep everything safe and strong.

What are some tips for keeping load limits accurate?

Use manufacturer’s instructions, keep load limits in mind, and double-check all calculations.

Industry Standards and Regulations

Summary of relevant industry standards governing screw load limits.. Discussion on the implications of noncompliance with these standards..

Many rules guide how screws should hold weight. These rules protect workers and ensure safety. They say how strong screws must be and what tests they need to pass. Not following these rules can cause serious problems.

- Accidents can happen if screws break.

- Companies can get fines or lawsuits.

- Trust can be lost among customers.

Industry standards aim to keep everyone safe. Knowing and following these rules is important for everyone involved.

Why do screw load limits matter?

Screw load limits matter because they ensure safety and product quality. They help avoid failures in machinery and structures.

Applications of Screw Load Limits

Examples of industries where understanding screw load limits is crucial (e.g., construction, manufacturing).. Case studies showcasing the reallife impact of load limit miscalculations..

Many industries rely on understanding screw load limits. For example, in construction, knowing these limits keeps buildings safe and strong. Would you want your house to wobble like a jelly on a plate? Not a chance! In manufacturing, screw load limits ensure machines run smoothly and don’t fall apart. Some funny mishaps have happened when people forget this, like a roller coaster with loose bolts. Yikes! Below is a table of amazing examples:

| Industry | Impact of Miscalculations |

|---|---|

| Construction | Unsafe buildings and accidents |

| Manufacturing | Machine failures and costly repairs |

Understanding screw load limits isn’t just smart; it’s essential! It keeps everything running like well-oiled gears. So, let’s screw in some brains and avoid crazy blunders!

Conclusion

In summary, understanding screw load limits is essential for safe and effective use. Knowing these limits helps you choose the right screws for your projects. Always check the specifications to avoid accidents. We encourage you to learn more about this topic to improve your skills. Remember, safe building leads to successful outcomes!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Screw Load Limit:

The screw load limit is how much weight a screw can hold without breaking. You can think of it like a strong or weak friend carrying something heavy. If you put too much weight on the screw, it might snap or come loose. Always check how much weight a screw can handle before using it. This helps keep things safe!

Sure! Please provide the question you want me to answer.

What Factors Influence The Load Limit Of A Screw In A Mechanical Assembly?

The load limit of a screw depends on a few key things. First, the material of the screw matters. Stronger materials can hold more weight. Second, the screw size affects how much weight it can handle. A bigger screw usually holds more than a small one. Finally, how tight the screw is also matters; a tighter screw can hold more load.

How Is The Screw Load Limit Calculated For Different Materials And Dimensions?

To find out how much weight a screw can hold, we look at the material it’s made from and its size. Different materials, like steel or plastic, have different strengths. We check the screw’s diameter and length, too. Then, we use special formulas to figure out the load limit. This way, we know how much the screw can safely hold.

What Are The Consequences Of Exceeding The Load Limit Of A Screw In A Connection?

When you put too much weight on a screw, it can break or come loose. This can cause things to fall apart or break. You might get hurt if something falls on you. It’s important to follow weight limits so that everything stays safe and works well. Always check how much a screw can hold before using it!

How Do Environmental Conditions, Such As Temperature And Humidity, Affect The Load Limit Of Screws?

Temperature and humidity change how strong screws can be. When it’s hot, screws can get weaker, making them hold less weight. In high humidity, moisture can make screws rust, which also weakens them. So, we need to think about the weather when using screws to hold things together. Keeping screws in a dry, cool place helps them stay strong!

What Testing Methods Are Commonly Used To Determine The Load Limits Of Various Screw Types?

To test how much weight screws can hold, we use different methods. One way is called a pull test. In this test, we pull on the screw until it comes out. Another method is called a torque test, where we twist the screw to see how much it can handle. Each test helps us learn about the screw’s strength.

Resource:

Understanding Tensile Strength in Materials: https://www.engineeringtoolbox.com/tensile-strength-d_372.html

Environmental Effects on Metal Performance: https://www.corrosionpedia.com/definition/1243/environmental-corrosion

Guide to Fastener Standards and Safety: https://www.astm.org/standards/fasteners.html

Basics of Torque and Tightening Techniques: https://www.boltscience.com/pages/tighten.htm