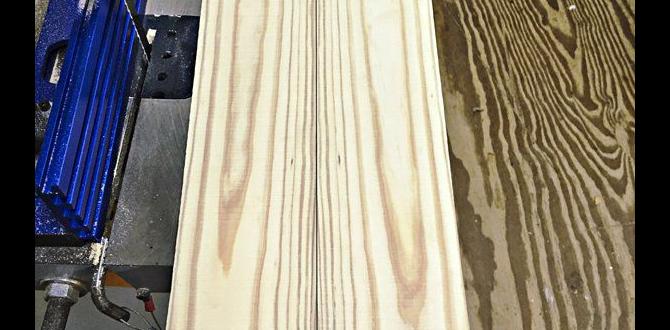

Have you ever wondered how to make thick wood more useful? Resawing thick wood on a bandsaw is a great way to do just that. Imagine turning one heavy piece of lumber into several thinner boards. This simple act can save money and create beautiful projects.

Many woodworkers enjoy the challenge of resawing. They love to see the grain patterns revealed inside the wood. Did you know some bandsaws can cut through wood that is up to 12 inches thick? With the right tools and techniques, you can transform lumber like a pro.

Are you ready to dive into the world of resawing? Whether you are a beginner or an experienced crafter, there is always something new to learn. Let’s explore how you can master this important skill and make the most of your thick wood pieces!

Table of Contents

Resawing Thick Wood On Bandsaw: Tips And Techniques

Resawing Thick Wood on Bandsaw

Resawing thick wood on a bandsaw opens up new possibilities for your woodworking projects. Imagine turning a single piece of lumber into multiple boards. This technique reduces waste and lets you explore more grain patterns. You’ll learn how to adjust your bandsaw for the best cuts and safety tips for handling heavy wood. Did you know that resawing can also save you money on materials? Discover how to make the most of your lumber with this valuable skill!Understanding Resawing and Its Importance

Definition of resawing. Advantages of resawing thick wood.Resawing is the process of cutting a thick piece of wood into thinner slices. Imagine a loaf of bread, but instead of bread, it’s a solid piece of oak! There are many reasons to resaw thick wood. First, it helps you create thinner boards for projects, saving material and money. You can also make cool designs using different wood patterns. Plus, it’s a great way to show off your woodworking skills. Who doesn’t want to impress their friends with shiny new shelves made from fancy wood?

| Advantages of Resawing |

|---|

| Creates thinner boards |

| Saves wood and costs |

| Enhances design possibilities |

| Improves woodworking skills |

Preparing Your Wood for Resawing

Selecting the right thick wood. Steps for measuring and marking the wood.Choosing the right thick wood is like picking a good friend for a fun adventure. Look for straight grain and minimal knots—those knots can be mood-killers later! Size matters too. Measure twice, cut once, right? Start by using a tape measure and mark with a pencil. You want those lines to be clear, like a road map to your lumber dreams!

| Step | Action |

|---|---|

| 1 | Select quality wood |

| 2 | Measure carefully |

| 3 | Mark your lines |

Setting Up Your Bandsaw for Optimal Performance

Adjusting blade tension and tracking. Ensuring proper alignment and safety features.First things first, you want your bandsaw to work like a charm! Start by adjusting the blade tension. Too tight, and it could snap like a bad rubber band; too loose, and it’s as useless as a chocolate teapot. Next, make sure the blade tracks straight. A wandering blade is like your dog chasing its tail—cute, but not really helpful!

Also, never skip checking alignment and safety features. Always wear goggles, unless you fancy wood chips in your eyes! Use the table below to ensure you’re all set:

| Step | Action |

|---|---|

| 1 | Adjust Blade Tension |

| 2 | Track the Blade |

| 3 | Check Alignment |

| 4 | Ensure Safety Features are Active |

These steps will make sure your bandsaw runs smoothly and safely. Happy sawing!

Technique for Resawing Thick Wood

Stepbystep process for effective resawing. Tips for maintaining accuracy and safety.To resaw thick wood like a pro, start by placing the wood flat on the bandsaw table. Make sure the wood is stable; you don’t want it dancing around! Next, align the blade to cut the desired thickness. Then, feed the wood slowly and steadily. Remember, patience is key—no need for a racing contest here! For safety, always wear goggles and use push sticks. Accuracy is vital, so double-check your measurements before cutting. Stay sharp, and your project will shine like a freshly polished apple!

| Step | Tip |

|---|---|

| 1. Set up bandsaw | Ensure the wood is flat and stable. |

| 2. Align blade | Adjust for the thickness you need. |

| 3. Feed wood | Go slow and steady for best results. |

| 4. Wear safety gear | Goggles and push sticks are your friends! |

Common Challenges and Solutions in Resawing

Identifying issues like blade drift and snipe. Practical solutions to overcome these challenges.Resawing thick wood can feel like a lumberjack adventure, but issues may pop up, so watch out! One big challenge is blade drift, which makes your cuts go off course like a lost puppy. Another sneaky problem is snipe, where the wood ends up with a little bite at the ends. To tackle these, check your blade tension and make sure your saw is aligned properly. A little adjustment can go a long way!

| Challenge | Solution |

|---|---|

| Blade Drift | Check tension and alignment. |

| Snipe | Start and end cuts carefully. |

Remember, a happy bandsaw means better wood cuts and fewer splinters. So don’t be shy—get that wood resawed like a pro!

Finishing Resawed Wood: Tips and Techniques

Sanding and finishing options for resawed surfaces. Best practices for storing resawed boards.After resawing thick wood, the finishing touch is key to making it shine. Start with sanding; smooth surfaces prevent splinters and make your project look pro. Use grits from coarse to fine—like you’d graduate from kindergarten to college! Remember, sanding in the direction of the grain avoids scratches. Once sanded, choose a finish. Oils, stains, or clear coats can add style. Store your boards flat and dry to prevent warping. A sturdy stack is like a well-made sandwich: it keeps everything in place!

| Finishing Option | Tip |

|---|---|

| Oil | Brings out the wood’s natural beauty. |

| Stain | Adds color and depth; test on scrap first! |

| Clear Coat | Seals and protects; use multiple layers. |

Safety Precautions to Consider

Essential safety gear for resawing. Safe operating practices for bandsaw users.Always prioritize safety when using a bandsaw. Wearing the right gear can protect you from accidents. Essential safety gear includes:

- Safety goggles to shield your eyes from dust and flying debris.

- Ear protection to guard against loud noise.

- Work gloves to improve grip while handling wood.

- Dust mask to keep your lungs safe from sawdust.

More tips for safe bandsaw use include keeping your hands clear of the blade, tightening loose clothing, and following the bandsaw’s instructions. Stay aware and focused at all times.

How can I stay safe while using a bandsaw?

Stay safe by using proper safety gear, keeping hands away from the blade, and following the bandsaw’s instructions.

Case Studies: Successful Resawing Projects

Examples of projects utilizing resawed wood. Lessons learned from experienced woodworkers.Woodworking adventures are always fun, especially when you resaw thick wood. Let’s peek at some cool projects! For instance, Tom transformed a hefty log into stunning tabletops. He learned that measuring twice saves time and wood. Sarah resawed wood for beautiful picture frames. She found that patience is key—rushing leads to splinters! Below is a table of some successful projects and the lessons learned:

| Woodworker | Project | Lesson Learned |

|---|---|---|

| Tom | Tabletops | Measure twice, cut once! |

| Sarah | Picture Frames | Patience prevents splinters! |

Every slice teaches something new. So, grab your bandsaw and let the magic begin!

Conclusion

In conclusion, resawing thick wood on a bandsaw is a valuable skill. It helps you create thin boards for various projects. Make sure you measure carefully and adjust your blade for best results. Practice makes perfect, so don’t hesitate to start. For more tips, check out our guides or watch online videos. Let’s get cutting and have fun!FAQs

What Techniques Can Be Used To Ensure Accurate And Even Resawing Of Thick Wood On A Bandsaw?To resaw thick wood on a bandsaw, you should use a good blade that’s sharp and the right size. Make sure to adjust the guides that hold the blade straight. You can also use a fence to keep the wood straight as you cut. Lastly, move the wood slowly and steadily through the saw to get an even cut.

How Do You Choose The Appropriate Blade Type And Size For Resawing Thick Wood?To choose the right blade for cutting thick wood, think about how wide the wood is. A blade that is thinner helps make straight cuts better. You also want a longer blade to cut through the thick parts. Look for a blade with fewer teeth, which helps it cut faster. Always remember: the right blade makes cutting easier and cleaner!

What Safety Precautions Should Be Taken When Resawing Thick Wood On A Bandsaw?When you resaw thick wood on a bandsaw, you should wear safety glasses to protect your eyes. Keep your hands away from the blade. Use pushsticks to guide the wood safely. Make sure the blade is sharp to avoid trouble. Lastly, always follow the machine’s instructions for a safe experience.

How Can You Set Up A Bandsaw For Optimal Performance When Resawing Thicker Stock?To set up a bandsaw for cutting thick wood, first, choose the right blade. Use a wide blade for better control. Next, adjust the tension on the blade so it is tight. Make sure the guides are close to the blade for support. Finally, set the speed of the saw for smooth cutting.

What Are Some Common Challenges Faced When Resawing Thick Wood, And How Can They Be Addressed?When you resaw thick wood, you might face some problems. The wood can wobble or shift while cutting. To fix this, use a good clamp to hold it still. You also need a sharp blade; a dull blade can make the cuts rough. Finally, take your time and go slow to get clean cuts.