Quick Summary:

Having trouble with your nailer? Don’t worry! This beginner-friendly guide covers common nailer issues and simple fixes. Learn how to identify problems, perform basic maintenance, and get your nailer working smoothly again for your DIY projects.

Hey DIYers! Jack Shaffer here from Nailerguy. Nothing stops a project in its tracks quite like a nailer that’s decided to take a break. It’s a total bummer when you’re ready to build, but your trusty nailer won’t fire, jams, or just acts plain weird. These tools are amazing for speeding up work, but like any tool, they need a little TLC sometimes. This guide is built specifically for you, the beginner, to help you understand why your nailer might be acting up and, more importantly, how to fix it. We’ll walk through some of the most common hiccups and give you simple, step-by-step solutions. Let’s get your nailer back in action so you can finish that project with confidence!

Table of Contents

Common Nailer Problems and How to Solve Them

It’s frustrating when your nailer doesn’t perform as expected, but most issues have straightforward solutions. Understanding these common problems will save you time, money, and a whole lot of headaches. We’ll break down the most frequent culprits and provide clear, actionable steps you can take right away.

1. The Nailer Won’t Fire (No Nail Comes Out)

This is probably the most common and concerning issue. You pull the trigger, and absolutely nothing happens. Don’t panic; there are several simple reasons why this occurs.

Possible Causes and Solutions:

- Low Air Pressure (Pneumatic Nailers): Your air compressor might be set too low, or not fully charged.

- Air Leak: Check all hose connections and hose itself for any visible damage or leaks. A loose connection can prevent proper air flow.

- Safety Contact Tip Not Engaged: Most nailers have a safety mechanism on the tip. You must press this firmly against the surface you’re nailing for it to fire.

- Depth Adjustment Too High: If the depth adjustment is set too deeply, the nailer might not drive the nail. Try adjusting it to a shallower setting.

- Tool Not Properly Triggered: Make sure you are pressing the trigger fully and that the safety contact tip is depressed at the same time.

- Internal Jam: Sometimes, a nail can get stuck internally, preventing firing. We’ll cover jams in the next section.

- Low Battery (Cordless Nailers): For battery-powered nailers, a depleted battery is the obvious reason. Ensure it’s fully charged.

Step-by-Step Check for Nailer Not Firing:

- Check Air Pressure (Pneumatic): Ensure your air compressor is turned on, has enough air, and the regulator is set to the recommended PSI for your nailer (check your nailer’s manual). For most framing nailers, this is around 90-120 PSI. Brad nailers and finish nailers often require less.

- Inspect Hose and Connections (Pneumatic): Listen for hissing sounds. Firmly push in all quick-disconnect fittings at both the compressor and the nailer. Examine the air hose for any cuts or cracks.

- Verify Safety Tip Engagement: Press the nose of the nailer firmly against a piece of scrap wood. You should hear a slight “click” or feel it engage. Ensure the tip isn’t obstructed.

- Adjust Depth Setting: Locate the depth adjustment wheel or lever on your nailer. Turn it to a less aggressive setting (usually counter-clockwise for shallower depth).

- Test Trigger and Safety Tip Together: Press the safety tip firmly against the wood and then pull the trigger fully.

- Check Battery (Cordless): If you have a cordless nailer, remove the battery and reinsert it firmly. If it’s still not working, try a fully charged backup battery if you have one.

- Look for Internal Jams: If the above steps don’t work, proceed to the “Nailer Jams” section.

2. Nailer Jams (Nails Get Stuck)

Nail jams are incredibly common, especially with new users or when using inferior fasteners. The good news is that most jams are quickly cleared with a few simple steps.

Why Do Nailers Jam?

- Incorrect Nail Size/Type: Using nails that are too long, too short, or the wrong gauge for your nailer is a prime cause of jams. Always check your nailer’s specifications.

- Driver Blade Issues: The driver blade (the part that strikes and drives the nail) can become bent or dull, leading to misfires and jams.

- Debris in the Magazine: Small pieces of wood, broken nails, or dirt can obstruct the nail track.

- Low Air Pressure: If the air pressure is too low, the nail may not be fully driven, and the next nail can get jammed behind it.

- Repeated Dry Firing: Firing the nailer repeatedly without a nail or material can damage the driver blade and cause jams.

How to Clear a Nail Jam:

- Disconnect Air/Battery: ALWAYS disconnect the air hose from a pneumatic nailer or remove the battery from a cordless nailer before attempting to clear a jam. Safety first!

- Open the Magazine/Nose: Most nailers have a mechanism to open the front of the magazine. This might involve sliding a latch, pressing a lever, or removing screws. Consult your nailer’s manual if you’re unsure.

- Remove Obstructions: Once open, look for the jammed nail. If it’s visible, try to gently pull it out. Sometimes you can use needle-nose pliers. If a driver blade is stuck, you might need to carefully nudge it back into place.

- Clear Debris: Use a brush or a blast of compressed air to remove any small wood fragments, dust, or broken nail pieces from the magazine and track.

- Check Driver Blade: With the magazine open, you can often see the driver blade. Ensure it’s straight and moves freely. If it’s bent, it might need professional repair.

- Close and Test: Carefully close the magazine, reconnect the air/battery, and test fire on a scrap piece of wood.

Pro Tip:

Always use high-quality nails specifically designed for your nailer model. Cheap nails can split, bend, and cause jams. Reputable brands like Paslode, Senco, and DeWalt offer a wide range of quality fasteners. Check out Toolingu’s fastener specifications guide for more details on different nail types.

3. Nails Not Driving Deep Enough

You’re getting ready to drive a nail, but it sticks out of the surface. This can be messy and require extra work to fix. Here’s why it happens and how to solve it.

Common Reasons for Nails Not Driving Deep:

- Insufficient Air Pressure (Pneumatic): The most frequent cause. Not enough air means not enough force to drive the nail.

- Depth Adjustment Set Too Shallow: The nail depth setting might be dialed back, preventing full insertion.

- Soft Wood Being Nailed: If you’re working with very soft materials like foam insulation or packing cardboard, the nailer might push the material away before the nail is driven.

- Driver Blade Not Fully Retracting: The driver blade might not be returning fully to its home position, impacting subsequent shots.

- Worn O-rings or Seals: Leaking seals can reduce the power delivered by the nailer.

Fixes for Shallow Nails:

- Increase Air Pressure: Gradually increase the air pressure from your compressor, testing after each increment. Stay within the nailer’s recommended range.

- Adjust Depth Setting: Turn the depth adjustment dial or lever on your nailer to a deeper setting (usually clockwise for deeper penetration).

- Use a Mallet (Carefully): For very soft materials, you might need to set a nail and then gently tap it flush with a rubber mallet. Be careful not to damage the surface.

- Inspect Driver Blade and Seals: If you suspect internal issues like a slow driver blade or leaks, it might be time for a deeper maintenance check or professional assistance.

4. Nails Driving Too Deep (Recessing)

On the flip side, sometimes nails go in too far, creating divots and damaging the surface. This is especially problematic when you want a flush finish.

Why Nails Sink Too Deep:

- Depth Adjustment Set Too Deep: The most obvious reason. The setting is simply too aggressive.

- Nailer Too Close to Edge: When nailing near the edge of a board, the material can split and give way, making the nail seem too deep.

- Soft Wood: Similar to not driving deep enough, if the wood is very soft, the nailer can compress the material excessively.

- Overshooting/Excessive Force: Sometimes, due to the shock of firing, the nailer can be driven harder into the material than intended.

How to Prevent Overshooting:

- Reduce Depth Setting: Turn the depth adjustment dial or lever on your nailer to a shallower setting (usually counter-clockwise for shallower penetration).

- Maintain Consistent Distance from Edge: Try to nail at least 1-2 inches from the edge of a board to avoid splitting.

- Moderate Pressure: Apply firm but not excessive pressure when placing the nailer against the workpiece.

- Consider Nailer Type: Some nailers are more powerful than others. A framing nailer might be overkill for fine trim work. Ensure you’re using the right tool for the job.

5. The Nail Pockets or Sits Crooked

Sometimes, a nail will sit at an angle or partially pop out, making for an unsightly finish. This is usually a sign of a specific issue with how the nail is being presented or driven.

Reasons for Crooked Nails:

- Loose Magazine: If the nail magazine is loose or not properly seated, nails can feed at an angle.

- Bent Driver Blade: A damaged driver blade will often drive nails inconsistently.

- Obstruction in the Nail Track: Even small bits of debris can cause a nail to deviate from its intended path.

- Angle of Nailer: Holding the nailer at a significant angle to the work surface will cause the nail to travel that angle.

- Nails Not Aligned Properly: Ensure the nails are loaded correctly in the magazine and are aligned with the track.

Fixing Crooked Nail Issues:

- Check Magazine Security: Ensure the nail magazine is firmly closed, latched, and aligned properly. Some magazines have pinch-point warnings, so be careful.

- Inspect Driver Blade: Look for any visible bends or damage. If it’s bent, it’s often best to get it replaced.

- Clean the Magazine and Track: Remove any debris that could interfere with nail feeding.

- Keep Nailer Square: Always try to place and fire the nailer as perpendicular to the work surface as possible for a straight nail.

- Proper Nail Loading: Double-check that the nails are seated correctly in the magazine and are pointing straight down the track.

6. Leaking Air (Pneumatic Nailers)

A constant hiss of escaping air not only wastes energy but also means your nailer won’t have the consistent power it needs.

Common Places for Air Leaks:

- Hose Connections: Where the air hose connects to the compressor and the nailer.

- Air Hose Itself: Cracks, cuts, or abrasions can lead to leaks.

- O-rings and Seals: Internal seals within the nailer body can wear out.

- Valve Stem: The part inside the trigger mechanism.

Troubleshooting Air Leaks:

- Perform the “Soap Test”: Mix some dish soap and water in a spray bottle. Spray suspected leak areas. Bubbles will form where air is escaping – an easy way to pinpoint the problem!

- Check Hose Connections: Ensure all fittings are securely tightened. If a fitting is damaged, replace it.

- Inspect the Air Hose: Look closely for any visible damage. If you find a leak, it’s best to replace the entire hose for safety.

- Listen for Leaks in the Nailer Body: If the leak isn’t at the hose connection, it might be internal. This often requires disassembly or professional repair.

- Check the Trigger Valve: Sometimes, debris can lodge in the trigger valve, causing a small leak. Compressed air can sometimes clear this.

For pneumatic nailers, maintaining proper air pressure is crucial. You can find recommended PSI ranges for common tools online, or in your tool’s manual. For example, a guide from Engine Schools Inc. explains the importance of compressed air systems.

Basic Nailer Maintenance for Longevity

Preventing problems is just as important as fixing them. A little routine maintenance goes a long way in keeping your nailer running smoothly and reliably.

Regular Maintenance Tasks:

- Cleanliness is Key: Wipe down your nailer after each use to remove dust and debris. Pay special attention to the nose and magazine.

- Lubrication (Pneumatic): For pneumatic nailers, use 1-2 drops of specialized pneumatic tool oil in the air inlet fitting before each use. This lubricates internal moving parts. Over-oiling can cause issues, so use sparingly.

- Check O-Rings and Seals: Periodically inspect rubber seals and O-rings for signs of wear or cracking. Replace them if they look damaged.

- Inspect Driver Blade: Regularly check the driver blade for bends or excessive wear.

- Keep Magazine Clean: Ensure the nail magazine is free of debris.

- Battery Care (Cordless): For cordless nailers, keep the batteries charged and store them properly according to the manufacturer’s instructions. Avoid exposing them to extreme temperatures.

When to Call a Professional

While this guide covers most beginner issues, some problems are beyond simple fixes. If you’ve tried the suggested solutions and your nailer is still malfunctioning, or if you suspect a serious internal issue (like a bent driver blade that you can’t easily remove, or major air leaks from the tool body), it’s best to:

- Consult Your Manual: Your tool’s manual often has a dedicated troubleshooting section.

- Contact the Manufacturer: They can offer specific advice or guide you on warranty claims.

- Take it to a Repair Shop: Many tool repair shops specialize in power tools and can fix complex issues.

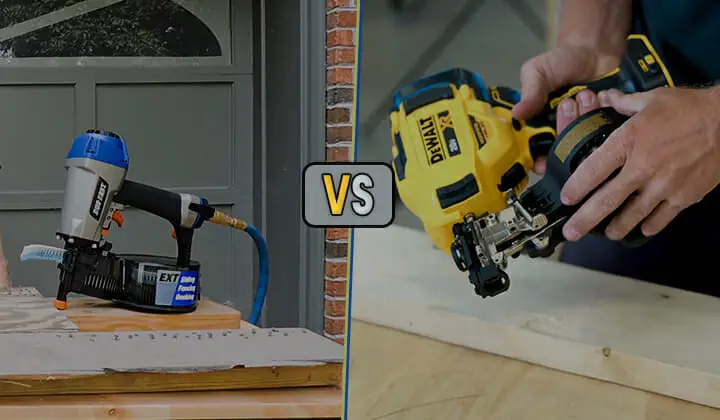

Understanding Different Nailer Types

Knowing your nailer type helps in troubleshooting. The fixes can vary slightly between them.

| Nailer Type | Power Source | Common Uses | Troubleshooting Notes |

|---|---|---|---|

| Framing Nailer | Pneumatic / Battery | Building walls, framing floors, roof sheathing | High power needed; often requires higher PSI. Jams can be heavier due to larger nails. |

| Finish Nailer | Pneumatic / Battery / Electric | Attaching baseboards, crown molding, trim, window/door casings | Needs precise depth control. Prone to “popping” nails proud if depth is set wrong. |

| Brad Nailer | Pneumatic / Battery / Electric | Attaching delicate trim, tiny moldings, crafts | Very fine nails; jams can be tricky. Gentle, consistent pressure needed. |

| Pin Nailer | Pneumatic / Battery | Holding small pieces together temporarily, very delicate trim | Uses very fine pins; no head on the nail. Must be held perfectly square. |

| Stapler | Pneumatic / Battery / Electric | Upholstery, attaching sheathing, fencing | Different fastener means different jam types. Check staple collation. |

Understanding the specific demands of each nailer type can prevent many issues. Always use the correct fasteners for your tool. For instance, using a framing nail in a finish nailer magazine is impossible and dangerous. The <a