Have you ever wondered why your nail gun suddenly loses pressure? It can be really frustrating, especially when you are in the middle of a project. Nail guns are powerful tools, but they need the right pressure to work well. Imagine trying to build a treehouse, but your tool won’t fire correctly. This can happen for several reasons.

First, a common cause of pressure loss might surprise you. It could be a tiny air leak. Even a small crack can stop your nail gun from working properly. Think about it! A small hole can lead to big problems.

In this article, we will explore nail gun pressure loss causes. We will give you helpful tips to fix these issues. So, let’s dive in and learn how to keep your nail gun firing strong!

Table of Contents

Nail Gun Pressure Loss Causes: Understanding The Issues

Nail Gun Pressure Loss Causes

Nail guns are handy tools, but they can sometimes lose pressure. This can happen for different reasons. First, look out for air leaks in the hose or fittings. A damaged hose can cause pressure drops. Second, dirty filters can block airflow and lead to pressure loss. Did you know that maintenance can extend the life of your nail gun? Regularly checking these factors helps keep your tool working well and ensures you finish projects faster!2. Analyzing Air Supply Issues

Importance of proper air supply for nail gun operation.. Effects of air compressor settings on nail gun performance..The air supply is key for a nail gun to work well. If the air pressure is too low, the nails may not shoot out properly. This can cause frustration during a project. For best results, check your air compressor settings. If the compressor pressure isn’t right, the nail gun may fail to perform. Proper air supply ensures your nail gun works smoothly and delivers consistent results.

What happens if the air compressor settings are incorrect?

If your air compressor pressure is too low or high, it can lead to jamming or weak nail placement. Always adjust the settings according to the nail gun’s requirements for safe and efficient use.

| Air Pressure Settings | Effects on Nail Gun |

|---|---|

| Low Pressure | Nails won’t drive in fully. |

| High Pressure | Nails may bend or break. |

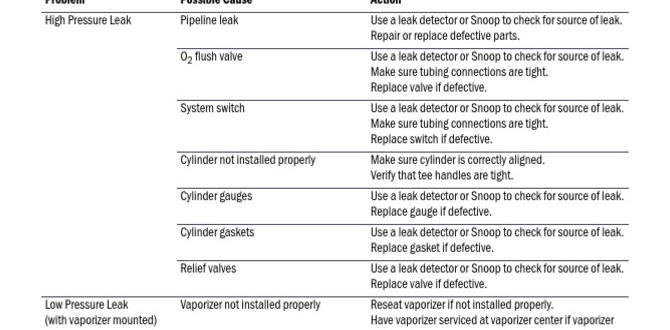

3. Exploring Leaks in the System

Signs of leaks in hoses and connections.. Steps to detect and fix air leaks in nail gun systems..Finding air leaks in nail gun systems is important. Leaks can waste air and slow down your work. Here are some signs of leaks:

- Funny noises from the nail gun

- Hoses that feel wet or damp

- Loss of pressure during use

Detecting and fixing leaks is simple:

- Check all hoses and connections.

- Look for cracks or breaks.

- Use soapy water to check for bubbles.

- Replace worn parts to fix leaks.

By keeping an eye on your nail gun, you’ll work better and faster.

How can I tell if there is a leak in my nail gun?

Look for sounds, damp hoses, and pressure loss. These are clear signs of a leak.

4. Examining Nail Gun Maintenance Practices

Key maintenance tasks to prevent pressure loss.. Recommended cleaning and lubrication routines..Taking care of a nail gun is important. Regular maintenance can stop pressure loss from happening. Here are some key tasks you can do:

- Check for leaks and replace damaged seals.

- Clean dust and debris from the tool.

- Lubricate moving parts with oil.

How often should you clean your nail gun?

It’s best to clean it after every use. This keeps it in good shape and helps it work right. Also, make sure to follow the manufacturer’s cleaning and lubrication guide for the best results.

5. Understanding Malfunctioning Components

Common components that may malfunction and cause pressure drops.. Troubleshooting steps for defective parts..Several parts in a nail gun can fail, leading to loss of pressure. Common culprits include the trigger, o-rings, and the air hose. If any of these parts malfunction, your nail gun won’t work right. To identify faulty components, consider these troubleshooting steps:

- Check the air supply.

- Inspect the trigger for damage.

- Examine o-rings for wear.

- Look for leaks in the air hose.

Proper maintenance helps prevent problems. Regular checks keep your nail gun firing smoothly.

What are common malfunctioning components of a nail gun?

The common malfunctioning parts of a nail gun include the trigger, o-rings, and the air hose. These parts affect air pressure and nail firing.

6. Impact of Environmental Factors

How temperature and humidity affect nail gun performance.. Seasonal impacts and adjustments to improve efficiency..Weather plays a big role in how well a nail gun works. Temperature can change how fast the air moves inside the gun. Hot days can make nails come out too quickly, while cold days can slow everything down. Humidity affects the air too. On wet days, moisture can make the nails stick together. It’s important to check the weather before using a nail gun, especially in different seasons.

- In summer, cut power to avoid jams.

- In winter, let the tool warm up.

- Use proper air pressure settings based on the season.

How do temperature and humidity affect nail gun performance?

Temperature and humidity can change how nails are driven, leading to pressure loss.

7. When to Seek Professional Help

Indicators that professional repair is necessary.. Benefits of consulting a technician for persistent issues..Sometimes, problems with a nail gun are too hard to fix alone. If it keeps losing pressure, it might be time for help. Here are some signs to watch for:

- Strange noises when using the nail gun.

- Frequent jams that slow down your work.

- Inconsistent firing that makes it hard to finish jobs.

Getting help from a technician has many benefits. Experts can:

- Quickly diagnose the issue.

- Fix problems you might not see.

- Ensure safety while using your tool.

Don’t hesitate to call a pro when things go wrong!

When should I call for help?

If your nail gun shows signs of pressure loss often, it’s time to seek a professional. Their experience can save you time and trouble.

Conclusion

In summary, nail gun pressure loss can happen due to clogged air lines, low air pressure, or damaged components. You should check your hoses and fittings regularly. Always keep your nail gun clean and well-maintained. If problems persist, consider reading the manual or seeking professional help. Stay informed to ensure your nail gun works efficiently every time!FAQs

Sure! Here Are Five Related Questions On The Topic Of Nail Gun Pressure Loss Causes:Nail gun pressure loss can happen for a few reasons. First, the air compressor might not be working right. If there are leaks in the hoses or connections, air can escape. Also, if you don’t have enough air in the tank, the nail gun won’t work well. Always check for these issues before using your nail gun.

Sure! Please provide the question you would like me to answer.

What Are The Common Reasons For Pressure Loss In Pneumatic Nail Guns?There are a few common reasons for pressure loss in pneumatic nail guns. First, check the air hose. If it’s cracked or has holes, air can escape. Next, look for leaks in the nail gun itself. If parts are worn or broken, they may let air out. Lastly, make sure your air compressor is working well and has enough pressure.

How Can A Clogged Air Filter Affect Nail Gun Performance And Pressure Stability?A clogged air filter can block the air needed for your nail gun. When the air can’t flow well, the nail gun may not work right. It can shoot nails too slowly or not at all. This can make it hard to hold things together. Keeping the air filter clean helps it work better!

What Role Do Damaged Hoses Play In Causing Pressure Loss In Nail Guns?Damaged hoses can let air escape from the nail gun. When air leaks, the nail gun doesn’t get enough pressure. This means it can’t drive nails properly. So, if you see a broken hose, it’s important to fix it!

How Does Insufficient Compressor Size Impact The Pressure Supply To A Nail Gun?If your air compressor is too small, it can’t supply enough air to the nail gun. This means the nail gun might not work well. You may find it hard to push nails all the way in. Sometimes, the nail gun could even stop working. A bigger compressor helps the nail gun work better!

What Maintenance Practices Can Prevent Pressure Loss In A Nail Gun During Use?To keep your nail gun working well, check the air hose for holes. Make sure the connections are tight. Clean the nail gun regularly to remove dust and debris. Also, oil the moving parts to keep them smooth. These steps help prevent pressure loss, so your nail gun works better!