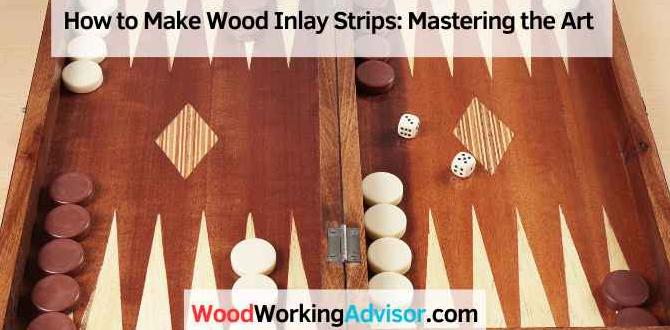

Have you ever wondered how to make wood inlay strips? Imagine taking pieces of wood and creating beautiful designs. This process can transform your projects into something special. It may sound tricky, but it’s easier than you think!

Wood inlay can add a magical touch to furniture or art. Picture a table with colorful patterns shining in the light. These designs can tell a story and catch everyone’s eye.

Did you know that inlay has been used for centuries? Ancient craftsmen mastered this art, and now you can too! By learning how to make wood inlay strips, you can create your own stunning pieces.

If you love working with wood, this is a skill you don’t want to miss. Are you ready to dive in and explore this amazing craft? Let’s get started!

Table of Contents

How To Make Wood Inlay Strips: Mastering The Art Of Craftsmanship

How to Make Wood Inlay Strips: Mastering the Art

Creating wood inlay strips can add beauty to your woodworking projects. Start with choosing your wood types; contrasting colors truly shine together. Next, cut your pieces accurately to fit snugly. Did you know that mixing different woods can create stunning patterns? Sanding the edges gives a smooth finish, ensuring your design stands out. It’s easier than it seems. With patience and practice, your inlay strips will impress everyone!Understanding Wood Inlay Strips

Definition and purpose of wood inlay strips. Historical significance and applications in woodworking.Wood inlay strips are like the sprinkles on a cupcake—they add charm and detail! These strips are thin pieces of wood used to create patterns and designs in furniture and art. Historically, they have shown up in many cultures, from ancient Egypt to modern woodworking. Craftsmen carved inlaid patterns to showcase skill and beauty. Today, inlays offer a unique way to enhance your projects. You might say, “A well-inlaid table leg stands taller than the rest!”

| Aspect | Details |

|---|---|

| Definition | Thin strips of wood for decoration. |

| Purpose | To enhance design and craftsmanship. |

| Historical Significance | Used across cultures for beauty. |

Essential Tools and Materials

List of necessary tools for creating inlay strips. Recommended types of wood for inlays.Creating wood inlay strips can be a fun project. First, gather your essential tools. You’ll need a saw, a chisel, and some sandpaper, among other things. Don’t forget your glue! It’s like the magic glue that holds everything together (but hopefully not your fingers!).

Now, for the wood, it’s best to choose types like walnut, maple, or cherry. They look fantastic and are easy to work with. Remember, you want your inlays to shine like a diamond on a ring. Here’s a quick list:

| Tool/Material | Description |

|---|---|

| Saw | For cutting the strips |

| Chisel | To fine-tune the shapes |

| Sandpaper | For a smooth finish |

| Glue | To bond pieces together |

| Wood Types | Walnut, maple, cherry |

With these tools and materials, you are ready to dive into the world of wood inlays. Let the magic of making pretty strips begin!

Preparation of Wood for Inlaying

Selecting the right wood pieces and grain orientation. Techniques for cutting wood strips to required dimensions.Choosing the right wood is the first step to making beautiful inlay strips. Look for strong, clear pieces with nice grain patterns. This will make your work stand out. Next, cut the wood strips to the right size. Use a sharp saw for clean edges. Be steady and focus on your cuts. Even a small mistake can ruin your design.

What is the best wood for inlay?

The best wood types for inlay are maple, walnut, and cherry. These woods offer great colors and patterns that catch the eye.

Here are some tips:

- Check for knots and cracks in the wood.

- Always measure twice before cutting.

- Use a miter saw for precise angles.

Designing Your Inlay Pattern

Tips for creating aesthetically pleasing inlay designs. Popular patterns and styles in wood inlay work.Creating a fantastic inlay design is like piecing together a puzzle—only with wood! Start by picking shapes that speak to you, like geometric patterns or nature themes. After all, who wouldn’t want a tree in their table? Look at classic styles, such as floral motifs or even stylish stripes, which never go out of fashion. To help, here’s a quick guide:

| Pattern Type | Description |

|---|---|

| Geometric | Sharp shapes, perfect for modern looks. |

| Natural | Swirls and leaves, bringing nature indoors! |

| Traditional | Classic designs that never age. |

Remember: less can be more, so don’t go overboard. A simple design can sparkle just as brightly as a complex one big enough to make your grandma gasp!

Techniques for Making Inlay Strips

Stepbystep guide to cutting and shaping the inlay strips. Methods for applying adhesive and securing the inlays.Cutting and shaping inlay strips can be a fun challenge. First, grab your favorite wood and a straight edge. Use a saw to cut strips into desired shapes. Remember, a steady hand is key—nobody likes a wobbly inlay! Apply adhesive generously but not too much, or it will look like a glue monster attacked. Press the inlays firmly and let them dry. Here’s a quick table to help:

| Step | Action |

|---|---|

| 1 | Cut wood into strips |

| 2 | Shape the strips as desired |

| 3 | Apply adhesive evenly |

| 4 | Press and secure inlays |

With some patience and practice, you’ll master the art of inlay strips! Just remember, even the pros started with a few goofs along the way.

Finishing Your Wood Inlay Project

Recommended finishing techniques for a polished look. Common pitfalls to avoid during the finishing process.To give your wood inlay project a smooth finish, choose the right topcoat. Popular options include polyurethane, lacquer, and oil finishes. Each type should be applied in thin layers. Always sand between coats for the best results.

Watch out for common mistakes. Avoid applying too much finish at once. This can cause drips and uneven spots. Don’t rush the drying time. Patience leads to a better look!

What finishing techniques should I use?

Use polyurethane for durability, lacquer for a fast-drying option, and oil finishes for a natural look. Sand your project after every coat for smoothness.Common pitfalls to avoid:

- Applying thick layers of finish.

- Skipping sandpaper between coats.

- Rushing the drying time.

Maintenance and Care for Inlays

Tips for preserving the longevity of wood inlays. Cleaning and restoration techniques for inlays over time.Taking care of your wood inlays helps them last longer. Regular maintenance is key. Here are some simple tips:

- Keep it clean: Use a soft cloth to wipe away dust.

- Watch out for moisture: Don’t let water sit on the inlays.

- Use polish: Apply a gentle wood polish to keep them shiny.

- Check for damage: Look for cracks and fix them quickly.

Restoration can help your inlays stay beautiful. Simple repairs can make a big difference.

How can I clean and restore wood inlays?

To clean wood inlays, use a damp cloth and gentle soap. For restoration, fill in scratches with wood filler or re-polish the surface.

Conclusion

In conclusion, making wood inlay strips is a fun and creative process. You need to choose your wood, cut it carefully, and glue the pieces together. Practice your skills and don’t be afraid to experiment. With patience, you can create beautiful designs. So grab your tools and start crafting! For more tips, check out woodworking books or online tutorials.FAQs

What Materials And Tools Are Essential For Creating Wood Inlay Strips?To make wood inlay strips, you need some basic materials and tools. First, gather different types of wood for the strips. You’ll also need glue to stick them together. A sharp knife or a saw will help you cut the wood into the right shapes. Finally, sandpaper is useful for smoothing the edges of your strips.

What Techniques Can Be Used To Achieve Precise Cuts For Inlay Pieces?To make precise cuts for inlay pieces, you can use a few handy techniques. First, a sharp knife or craft blade helps you get clean edges. You can also use a ruler to measure and draw straight lines. If you have a computer, a laser cutter can make exact cuts for you. Lastly, practice makes perfect, so keep trying!

How Can I Choose The Right Types Of Wood For A Visually Appealing Inlay Design?To choose the right types of wood for your inlay design, look for colors and patterns that you like. You can mix light and dark woods for a nice contrast. Try using different textures, too, like smooth and rough. Think about how the colors will work together and make a sketch first. This way, you can see what looks good before you start!

What Adhesive Methods Work Best For Successfully Bonding Inlay Strips To A Wood Surface?To bond inlay strips to a wood surface, you can use wood glue or epoxy. Wood glue is easy to apply and dries clear. Epoxy is a strong glue that works well for tough jobs. Make sure to press the strips down firmly and let the glue dry completely. This way, they will stay in place.

What Finishing Techniques Enhance The Overall Appearance And Durability Of Wood Inlays?To make wood inlays look better and last longer, you can use a few finishing techniques. First, sanding the surface smooth helps the wood feel nice. Next, applying a wood stain adds color and makes the design pop. Finally, a clear coat of sealer or varnish protects it from scratches and water. These steps make your wood inlays shine and stay beautiful for a long time.