Have you ever tried building something with wood? If you have, you know how important it is to use the right tools. One tool that can make your project much easier is a framing nailer, especially when working with engineered lumber.

Imagine quickly and neatly connecting beams without the hassle of hammering nails by hand. Sounds great, right? A framing nailer can do just that! It fires nails with speed and power, making your construction tasks faster and more fun.

Did you know that engineered lumber is stronger than regular wood? It holds up well and is often used in homes today. This means using a framing nailer with engineered lumber can give your project a solid foundation.

Whether you’re a novice builder or a seasoned pro, understanding how to use a framing nailer for engineered lumber can boost your skills. Are you ready to dive into the world of quick, high-quality construction? Let’s explore!

Table of Contents

The Best Framing Nailer For Engineered Lumber: A Comprehensive Guide

Framing Nailer for Engineered Lumber

Engineered lumber is popular in modern construction. A framing nailer makes using it easier and faster. These tools shoot nails deep into strong materials, providing durability. Did you know that using the right nail size can change your project’s outcome? Choosing a nailer specifically designed for engineered wood ensures better performance. Imagine completing a big project in half the time! Learn the advantages of using a framing nailer for your next building task.Understanding Engineered Lumber

Definition and types of engineered lumber. Advantages of using engineered lumber in construction.Engineered lumber is like the superhero of construction materials! It’s made by bonding together small pieces of wood, creating strong and stable beams. The most popular types include laminated veneer lumber (LVL), glued laminated timber (glulam), and oriented strand board (OSB). Using engineered lumber comes with perks like being more affordable and reducing waste. Just think about it: fewer trees are harmed, and structures can withstand more stress. It’s strong, it’s smart, and it won’t complain if you ask it to hold your roof up!

| Type | Advantages |

|---|---|

| LVL | Great for beams and headers |

| Glulam | Perfect for arches and large spans |

| OSB | Cost-effective and versatile |

Benefits of Using a Framing Nailer with Engineered Lumber

Efficiency and speed in framing projects. Enhanced precision and reduced labor costs.Using a framing nailer with engineered lumber makes building faster and easier. This tool helps you work quickly on framing projects. It saves time and energy. You can finish jobs in less time. Precision is another benefit; nails go in straight, making projects stronger. Less time spent means lower costs too. You’ll spend less on labor overall. Here are some key advantages:

- Efficiency: Nailers complete tasks quickly.

- Speed: Less time for each project.

- Precision: Accurate nail placement.

- Reduced labor costs: Fewer workers needed for the job.

Why should I use a framing nailer for engineered lumber?

Using a framing nailer cuts your **work time** in half. You can maintain high quality while saving money on labor costs.

Choosing the Right Framing Nailer for Engineered Lumber

Factors to consider (nail type, power, weight). Top brands and models recommended for engineered lumber.Choosing the best framing nailer for engineered lumber is like picking the right superhero for your construction job. First, consider the nail type; make sure it matches the engineered wood. Then, think about power, since some woods like to be extra stubborn. Finally, check the weight of the nailer – a heavy one can feel like lifting weights at the gym! Some top brands you might like include Paslode and Hitachi, known for their reliable models.

| Brand | Model | Key Feature |

|---|---|---|

| Paslode | Paslode 905600 | Lightweight and powerful |

| Hitachi | Hitachi NR90AES1 | Great for engineered wood |

Remember, a good nailer can help you build strong structures without turning your project into a comedy of errors!

Techniques for Nailing Engineered Lumber

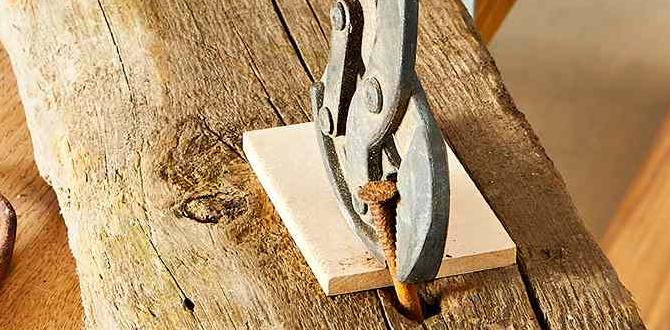

Best practices for nailing to avoid damage. Tips for securing joints and connections.Using a framing nailer for engineered lumber can be great if you follow some simple techniques. First, always check the angle before you nail. This helps prevent damage. Next, secure joints tightly. Properly securing connections makes structures stronger. Here are some tips:

- Create pilot holes if needed. This reduces splitting.

- Use the right nail size for your project.

- Keep your nailer clean and maintained. This ensures good performance.

These steps will help you nail safely and effectively!

What are ways to avoid damage when nailing?

Always check the nailing angle and use pilot holes. This protects the lumber from splits or cracks.

Maintenance and Care for Your Framing Nailer

Routine maintenance tips for longevity. Troubleshooting common issues with framing nailers.Taking care of your framing nailer helps it last longer, like a pet that requires food and love! Start with regular cleaning to avoid hiccups. Wipe it down, and check for dirt and dust. If the nails start misfiring, check the air pressure. It can be like a tired dog—just needs a little boost!

| Maintenance Tip | Action |

|---|---|

| Regular Cleaning | Wipe down and check for debris. |

| Check Air Pressure | Adjust if nails misfire. |

| Lubricate | Apply oil to keep parts moving smoothly! |

Don’t forget to inspect for worn parts. It’s like checking your shoes before a dance—nobody wants a toe stub! By following these simple steps, you’ll enjoy smooth sailing (and nailing!) with your tool. After all, a well-kept tool is a happy tool!

Safety Tips When Using a Framing Nailer

Essential safety equipment to use. Best practices for preventing accidents during use.When using a framing nailer, safety is key. Always wear the right gear to protect yourself. This includes:

- Safety goggles to shield your eyes.

- Hearing protection to block loud sounds.

- Gloves to keep your hands safe.

- Steel-toed boots to protect your feet.

Follow these best practices to avoid accidents:

- Always point the nailer away from yourself and others.

- Keep your fingers clear of the firing area.

- Check for obstructed paths before nailing.

Remember, safety comes first! Enjoy your project, but be careful. Your safety matters.

What should I wear while using a framing nailer?

Wear goggles, gloves, ear protection, and steel-toed boots to stay safe. These items will help protect you from flying debris and loud noises.

Conclusion

In summary, a framing nailer is essential for working with engineered lumber. It saves time and makes projects easier. Always choose a nailer that matches your materials. Remember to follow safety tips while using it. We encourage you to explore different models and read reviews to find the best fit for your needs. Happy building!FAQs

Here Are Five Questions Related To Framing Nailers For Engineered Lumber:Sure! A framing nailer is a tool that helps us put together wooden parts. It drives nails into wood very fast. Engineered lumber is strong wood made from smaller pieces glued together. We need special nails to use with this strong wood. This helps our buildings stay safe and sturdy!

Sure! Please provide the question you would like me to answer.

What Type Of Nails Are Recommended For Use With A Framing Nailer When Working With Engineered Lumber?When using a framing nailer with engineered lumber, you should use special nails called “ring shank nails.” These nails have small rings that help them grip better. You can also use galvanized nails, which resist rust. Choose nails that are the right length for your project, usually around 3 to 3.5 inches long. Always read the nailer’s instructions to make sure you’re using the right type.

How Does The Density Of Engineered Lumber Affect The Performance Of A Framing Nailer?The density of engineered lumber changes how well a framing nailer works. Denser wood is tougher, so the nailer must work harder to drive nails in. This can cause the tool to jam or wear out faster. If the wood is less dense, the nailer can go in easily and work better. So, knowing the wood’s density helps us use the nailer more effectively.

What Are The Key Features To Consider When Selecting A Framing Nailer Specifically For Engineered Lumber Projects?When choosing a framing nailer for engineered lumber, look for a few important things. First, make sure it can handle thicker materials since engineered lumber is stronger. Then, check if it uses the right type of nails that fit well and hold strong. You also want a nailer that is easy to use and not too heavy. Lastly, a good safety feature can help you work without accidents.

Are There Any Safety Precautions To Take When Using A Framing Nailer On Engineered Lumber Compared To Traditional Wood?Yes, there are some safety things to remember. First, wear safety glasses to protect your eyes from flying bits. Second, check your nailer to make sure it works well. Engineered lumber can be harder, so use the right nails. Finally, always keep your hands away from the nailer’s tip when you fire it.

How Does The Cost Of Framing Nailers Vary When Designed For Engineered Lumber Versus Standard Framing Materials?Framing nailers for engineered lumber usually cost more than those for standard materials. Engineered lumber is stronger and needs special tools. We pay extra to get the right nailer for these tough materials. So, if you’re working with engineered lumber, expect to spend a bit more.