Do you ever wonder how big wooden pallets are made so quickly? It all comes down to the tools used for the job. One of the best tools for pallet jobs is the coil nailer. This handy device saves time and makes building pallets a breeze.

Imagine having to hammer each nail by hand. That task could take forever! With a coil nailer, you can shoot nails quickly and easily. This means you finish your project faster and with less effort.

What’s more surprising is how many professional builders rely on this tool every day. They trust coil nailers to handle tough jobs without hiccups. It’s no wonder these machines are a favorite for pallet makers everywhere.

In this article, we will explore the benefits of using a coil nailer for pallet jobs. You’ll learn why it’s worth considering for your next project. Stick around to discover how this tool can transform your work!

Table of Contents

The Best Coil Nailer For Pallet Jobs: Top Picks And Tips

Coil Nailer for Pallet Jobs

Why struggle with hammer and nails when a coil nailer can do the work faster? This tool is perfect for pallet assembly. It uses long coils of nails, allowing for quick fastening. You’ll save time and energy. Did you know that using a coil nailer can increase productivity by up to 50%? Imagine finishing your projects sooner! Whether you’re a professional or a DIY enthusiast, a coil nailer is a smart choice for making pallets.Understanding Coil Nailers

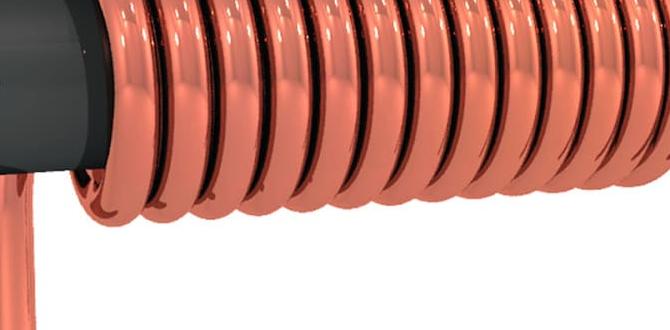

Definition and basic function of coil nailers. Types of coil nailers and their specific uses.Coil nailers are powerful tools that help with nailing wood together. They use coils of nails, allowing for quick and easy work. There are different types of coil nailers:

- Framing Coil Nailers: Ideal for big projects like building homes.

- Finish Coil Nailers: Great for detailed work, like making furniture.

- Roofing Coil Nailers: Used mostly for putting down shingles.

Each type serves a special purpose, making work faster and easier. Choosing the right one can make a big difference in any job, especially pallet work!

Benefits of Using Coil Nailers for Pallet Construction

Increased speed and efficiency over manual nailing. Consistent nail placement and reduced labor costs.Using coil nailers for pallet construction saves time and energy. They drive nails much faster than doing it by hand. This means you can finish more pallets in less time. Consistent nail placement happens with every nail, so your pallets are strong. This tool also lowers labor costs. Less time means fewer workers needed, making the whole process cheaper. Overall, coil nailers turn a hard job into an easy, quick one.

What are the key benefits of coil nailers for pallet jobs?

Coil nailers improve speed and accuracy, cut down on labor costs, and help create sturdy pallets quickly.

Key Features to Look for in a Coil Nailer

Nail size and type compatibility. Depth adjustment mechanisms for precision.Choosing the right coil nailer is like finding the perfect snack—it’s all about what fits! Check for nail size and type compatibility. Some nailers only work with specific nails, and that can ruin any pallet project faster than a runaway nail. Don’t forget about depth adjustment mechanisms. This handy feature helps you set how deep the nails go, ensuring they don’t peek out like a shy hedgehog. Look for these features, and you’ll nail it every time!

| Feature | Importance |

|---|---|

| Nail Size Compatibility | Ensures the nailer fits the nails |

| Depth Adjustment | Controls how deep nails go |

Safety Tips for Using Coil Nailers

Essential safety gear and precautions. Common mistakes to avoid while operating.Using a coil nailer can be fun, but safety comes first! Always wear protective goggles, earplugs, and sturdy gloves to keep safe from flying nails and loud noises. Avoid making common mistakes, like not checking the nail capacity or mishandling the tool. Remember, don’t aim it at anyone—even if they’re teasing you about your skills! The best way to avoid accidents is to follow safety tips. Here’s a table to remember:

| Safety Gear | Precautions |

|---|---|

| Protective Goggles | Always wear them to shield your eyes. |

| Earplugs | Use them to protect your hearing. |

| Sturdy Gloves | Wear gloves for a better grip and safety. |

| Check Nail Capacity | Ensure it’s filled properly before starting. |

So gear up, stay aware, and have some laughs while you nail those pallets!

Maintenance and Care for Your Coil Nailer

Regular maintenance routines to extend lifespan. Troubleshooting common issues with coil nailers.To keep your coil nailer working well, regular care is essential. Simple steps can make a big difference:

- Clean the nailer after each use to remove dust and debris.

- Lubricate moving parts to avoid rust and wear.

- Check air hoses for leaks and replace if needed.

- Inspect the nails—bent or damaged nails can cause jams.

If you notice issues, such as misfires or jams, here’s how to troubleshoot:

- Ensure nails are loaded correctly.

- Adjust the pressure settings on your compressor.

- Look for foreign objects causing blockages.

By following these tips, you can extend the lifespan of your tool and keep your projects running smoothly.

How do I maintain my coil nailer?

Regular cleaning, lubrication, and inspection can keep your coil nailer in great shape.

Cost Considerations: Balancing Quality and Budget

Price range for different models. Evaluating value for money in the context of pallet jobs.Choosing a coil nailer for pallet jobs means balancing quality and budget. Generally, prices range from $100 to $400, depending on the brand and features. Higher-priced models often offer better durability and speed, which can be important for heavy use. Evaluating value for money is vital. You want a tool that will last but not break the bank. A trusted model may save money on repairs in the long run.

How much should I spend on a coil nailer?

It’s best to spend between $200 and $300 for a reliable coil nailer. These models often balance quality and affordability, making them great for pallet work.

Price Breakdown of Coil Nailers

- Basic Models: $100 – $200 (good for occasional use)

- Mid-Range Models: $200 – $300 (best for consistent pallet jobs)

- Professional Models: $300 – $400 (ideal for daily, heavy-duty tasks)

User Reviews and Real-World Experiences

Analysis of feedback from professional pallet builders. Case studies illustrating effective use of coil nailers in pallet production.Many professional pallet builders share their thoughts on coil nailers, and they are mostly positive. Builders say these tools speed up their work and make it easier to assemble pallets quickly. Real-life examples show how effective these nailers really are. For instance, some builders noted a 25% increase in productivity. Wow! That’s more pallets made in less time!

| User Feedback | Case Study Results |

|---|---|

| “This thing is a time-saver!” | 25% faster production |

| “Very reliable and easy to use.” | Less tool downtime |

| “I love how it makes my job easier!” | Reduced manual effort |

Using a coil nailer properly can transform the way pallets are built. The trick is knowing how to make the best of it. Remember, become a coil nailer ninja, and you’ll get those pallets flying off the shelf!

Conclusion

In conclusion, a coil nailer is perfect for pallet jobs. It saves you time and helps you work faster. You get more done with less effort. Understanding its features will boost your projects. If you’re ready to improve your skills, consider trying one out. For more tips, check out guides or videos on using a coil nailer effectively!FAQs

What Are The Key Features To Look For When Selecting A Coil Nailer Specifically For Pallet Manufacturing Jobs?When choosing a coil nailer for making pallets, look for a few important things. First, check the weight; a lighter nailer is easier to use all day. Next, find one with a large magazine that holds many nails, so you don’t have to refill often. Also, make sure it can handle different nail sizes for different types of pallets. Finally, a good safety feature will help keep you safe while you work.

How Does The Use Of A Coil Nailer Improve Efficiency And Productivity In Pallet Assembly Compared To Traditional Nailing Methods?Using a coil nailer makes building pallets faster and easier. You can load many nails at once, so you don’t have to stop often. This helps you finish your work quickly. With a coil nailer, you can also hit nails in more places without using a hammer. This means you save time and can make more pallets.

What Types Of Fasteners Are Compatible With Coil Nailers For Pallet Construction, And How Do They Affect The Overall Strength Of The Pallet?Coil nailers use special nails called coil nails for pallet construction. These nails are strong and hold the wooden parts together well. The more nails you use, the stronger the pallet becomes. Strong pallets can carry heavier loads without breaking. Always choose the right nails to make sure your pallet is safe and sturdy!

Can A Coil Nailer Be Used For Both Softwood And Hardwood Pallets, And What Adjustments Are Needed For Different Materials?Yes, you can use a coil nailer for both softwood and hardwood pallets. For softwood, use shorter nails. For hardwood, switch to longer nails and adjust the pressure. This helps the nails go in better. Always check which nails work best for your project!

What Safety Precautions Should Be Taken When Operating A Coil Nailer In A Pallet Production Environment?When using a coil nailer, we need to wear safety glasses to protect our eyes. Always keep our hands away from the nail area when it’s working. Make sure to check the tool for any damage before using it. We should also keep our workspace clean and organized to avoid trips or accidents. Lastly, always follow the instructions if you’re unsure about how to use it safely.