Have you ever watched a bandsaw slice through wood like butter? It’s amazing to see how smoothly it works when its blade is sharp. But what happens when that blade gets dull? Things can get tricky. The cuts may become rough and uneven. That’s where a bandsaw blade sharpening service comes in handy.

Imagine trying to cut a piece of wood with a butter knife. Frustrating, right? A reliable sharpening service helps keep your bandsaw blade in top shape. This way, you can tackle any project with confidence. Whether you are a woodworker, a hobbyist, or just starting out, knowing about blade sharpening can save you time and effort.

Did you know that keeping your blade sharp can actually extend its life? This small task can make a huge difference in your work. Let’s explore why a bandsaw blade sharpening service is essential for anyone who loves to work with wood.

Table of Contents

Bandsaw Blade Sharpening Service: Enhance Cutting Precision

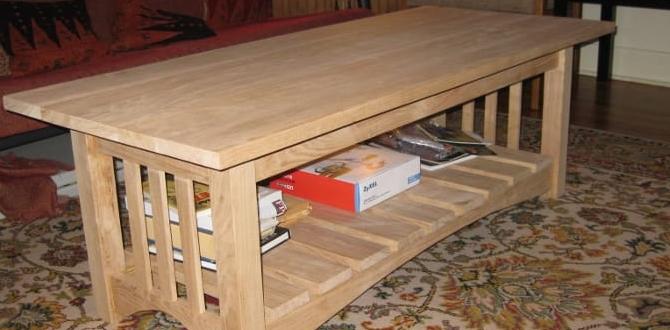

Do your cuts feel rough or uneven? A **bandsaw blade sharpening service** can bring your blade back to life. Regular sharpening helps extend the blade’s life, ensuring cleaner, smoother cuts. Imagine slicing through wood like butter! Many people don’t realize that dull blades waste time and effort. By using a professional sharpening service, you guarantee precision and performance. Plus, it can save you money on new blades. Curious about the benefits? Don’t let dull blades hold you back!

Importance of Bandsaw Blade Sharpening

Enhances cutting efficiency. Prolongs the lifespan of the blade.

Having a sharp bandsaw blade means better cuts. A sharp blade enhances cutting efficiency, making it easier to slice through materials. This can save time and effort. It also prolongs the lifespan of the blade. A well-maintained blade lasts longer and works better. Regular sharpening helps you get the most out of your investment.

Why is sharpening important?

Sharpening your bandsaw blade keeps it effective and saves money. Regular maintenance leads to better quality cuts and a longer-lasting blade.

- Better performance in cuts.

- Less strain on your machine.

- Saves on replacement costs.

Signs Your Bandsaw Blade Needs Sharpening

Dull cuts and increased effort required. Visible damage or wear on blade teeth.

When your bandsaw blade struggles, pay attention. Dull cuts are a big sign. If you notice that the blade is tearing instead of slicing, it’s time for action. You might also feel like you are pushing harder when you saw. This means it needs sharpening. Next, look closely at the blade teeth. If they seem worn or damaged, don’t ignore it. A sharp blade helps you work better and safer.

How can I check for blade damage?

Inspecting your blade is easy. Look for these signs:

- Visible nicks or chips on teeth.

- Teeth that look flattened or worn down.

- Signs of rust or discoloration.

Taking care of your bandsaw blade keeps it working well. A sharp blade can make your cutting tasks effortless.

Benefits of Professional Sharpening Services

Precision sharpening for optimal performance. Expertise and experience of professionals.

Getting your bandsaw blades sharpened by professionals offers many perks. First, they provide precision sharpening that enhances the blade’s performance. A sharp blade cuts smoothly, making your work easier. Plus, experts have years of training, so they know the best techniques. You won’t have to worry about uneven cuts or dull edges. Remember, a well-sharpened blade is like a superhero—ready to save the day!

| Benefit | Description |

|---|---|

| Precision | Sharper blades lead to cleaner cuts. |

| Expertise | Professionals know the ins and outs of blade care. |

Common Methods of Bandsaw Blade Sharpening

Manual vs. machine sharpening techniques. Advantages and disadvantages of each method.

There are two main ways to sharpen bandsaw blades: manual and machine sharpening. Manual sharpening involves using hand tools. It’s low-cost and gives you control. But, it takes time and skill. On the other hand, machine sharpening uses machines for fast results. It’s efficient but can be expensive. Each method has pros and cons to consider.

- Manual Sharpening: Cost-effective, but slower and needs practice.

- Machine Sharpening: Fast and precise, but more costly upfront.

What is better: manual or machine sharpening?

Machine sharpening is often faster, while manual sharpening allows for a personal touch. Your choice depends on your budget and skills.

How to Choose a Reliable Bandsaw Blade Sharpening Service

Factors to consider: experience, reputation, and pricing. Questions to ask potential service providers.

Finding a good sharpening service for your bandsaw blade is important. Look for these factors: experience, reputation, and pricing. Check how long the service has been in business. Ask friends or online reviews for feedback. Make sure the prices are fair and fit your budget. Here are some questions you could ask:

- How long have you been sharpening bandsaw blades?

- Can you show me reviews from other customers?

- What are your prices for sharpening?

Having clear answers can help you make a better choice!

What should I ask a bandsaw blade sharpening service?

Start by asking about their experience and client feedback. Inquire about turn-around time and pricing too.

DIY Bandsaw Blade Sharpening Techniques

Tools required for athome sharpening. Stepbystep process for sharpening blades.

Sharpening your bandsaw blade at home is easy! You need a few simple tools. First, gather a file, safety goggles, and gloves. These will help you stay safe while working. Here’s how to sharpen the blade:

- First, remove the blade from the bandsaw.

- Next, clean the blade to remove any debris.

- Then, use the file to sharpen each tooth evenly.

- Finally, reattach the blade when you’re done.

With practice, your blades will stay sharp and cut better!

What tools do I need for sharpening my bandsaw blade?

You need a file, safety goggles, and gloves to sharpen your bandsaw blade safely and effectively.

Cost Analysis of Bandsaw Blade Sharpening Services

Typical pricing models and what to expect. Comparison between professional and DIY sharpening costs.

Shopping for bandsaw blade sharpening can surprise you with different prices. Typically, a professional service can cost between $10 to $20 per blade. Expect top-notch results with sharper edges that make cutting feel like a breeze! Meanwhile, if you’re handy and feel adventurous, DIY sharpening kits start around $20, but be warned: it’s a test of patience. If you mess it up, you might spend more correcting your blunders!

| Service | Cost |

|---|---|

| Professional Sharpening | $10 – $20 |

| DIY Sharpening Kit | From $20 |

You get what you pay for, as they say! Investing in a pro can lead to longer-lasting blades. Remember, a sharp blade is a happy blade!

Maintaining Your Bandsaw Blade After Sharpening

Best practices for blade care and maintenance. Tips for improving blade longevity and performance.

Keeping your bandsaw blade happy after sharpening is crucial. Treat it well, and it will treat you well! First, always clean the blade after use. Sawdust can make it grumpy and less sharp. Store the blade in a dry place to prevent rust. Did you know that a sharp blade can reduce cutting time by up to 50%? That’s like getting a double scoop of ice cream without paying extra! Here’s a quick care tip: regularly check for any damage. A tiny ding can lead to big problems.

| Best Practices for Blade Care | Tips for Longevity |

|---|---|

| Clean the blade after every use. | Store in a dry place. |

| Inspect for damage regularly. | Use the correct tension. |

| Lubricate to reduce friction. | Avoid cutting hard materials. |

Conclusion

In conclusion, a bandsaw blade sharpening service keeps your tools sharp and effective. Regular sharpening saves you money and time. It helps your projects stay smooth and accurate. If you want to get the best from your bandsaw, consider using a sharpening service. Explore local options or learn to sharpen them yourself for the best results!

FAQs

What Are The Signs That My Bandsaw Blade Needs Sharpening, And How Often Should I Have It Serviced?

You know your bandsaw blade needs sharpening if it cuts slower or if you see rough edges on the wood. If it starts making strange noises or if the wood keeps getting stuck, it’s time to sharpen it. To keep things running well, you should check the blade often and sharpen it about every 5 to 10 hours of use.

What Techniques Or Equipment Do Professional Bandsaw Blade Sharpening Services Use To Ensure Precision And Longevity?

Professional bandsaw blade sharpening services use special machines to sharpen the blades. They carefully check each tooth to make sure it’s the right shape. Then, they grind the teeth evenly to help the blades last longer. Using cool water during sharpening helps prevent damage. This makes sure your blades cut well and stay sharp for a long time.

Can I Sharpen My Bandsaw Blades At Home, Or Is It Best To Use A Professional Sharpening Service?

Yes, you can sharpen your bandsaw blades at home if you have the right tools and skills. You need to be careful and do it right, or you might break the blade. Using a professional sharpening service is easier and usually gives better results. If you’re not sure, it might be best to let a pro handle it.

How Does The Type Of Material Being Cut Affect The Frequency And Method Of Bandsaw Blade Sharpening?

The material you cut affects how often you need to sharpen your bandsaw blade. If you cut hard materials like metal, the blade gets dull quickly, so we sharpen it more often. For softer things like wood, the blade stays sharp longer. This means we don’t need to sharpen as frequently. Different materials may also need different sharpening methods, depending on how tough they are.

What Factors Should I Consider When Choosing A Bandsaw Blade Sharpening Service To Ensure Quality Results?

When choosing a bandsaw blade sharpening service, you should look for experience. Find a company that has been doing this for a long time. Check their reviews to see what other people say. You also want to know if they use good tools and techniques. Finally, ask about their prices to find something that fits your budget.

Resource:

-

Blade Maintenance Safety Tips: https://www.osha.gov/etools/machine-guarding/saws/band-saws

-

Understanding Bandsaw Tooth Geometry: https://www.popularwoodworking.com/techniques/tooth-geometry/

-

How Often Should You Sharpen Tools?: https://www.woodmagazine.com/tool-reviews/hand-tools/how-often-should-you-sharpen-your-tools

-

Choosing Between Manual and Machine Tool Maintenance: https://www.canadianmetalworking.com/canadianmetalworking/article/machining/manual-versus-cnc-maintenance