Have you ever tried to cut wood with a bandsaw that just doesn’t seem to work right? It can be so frustrating! A simple tweak could change everything. One of the most important adjustments is to the blade guides.

Blade guides help keep the saw blade steady as it cuts. This means smoother cuts and safer operation. But how do you adjust them? It may sound tricky, but it’s easier than you think.

Imagine making a perfect cut on your next project. Wouldn’t that feel great? Knowing how to adjust blade guides can help you achieve that. Plus, it can keep your bandsaw in top shape.

In this article, we’ll explore the steps to adjust the blade guides on your bandsaw. You’ll learn why it matters and how to do it right. Let’s get started on making your cutting experience truly awesome!

Table of Contents

Adjusting Blade Guides On Bandsaws: A Comprehensive Guide

Adjusting Blade Guides on Bandsaws

Adjusting blade guides on bandsaws is essential for precise cuts. When guides are set correctly, they keep the blade stable and reduce drift. To adjust them, start by aligning the guides close to the blade, ensuring they move smoothly. Did you know that improper adjustments can cause the blade to wear out faster? Keeping challenges in mind will help you maintain a well-functioning bandsaw for all your projects. Remember, small adjustments can lead to big improvements!Understanding Blade Guides

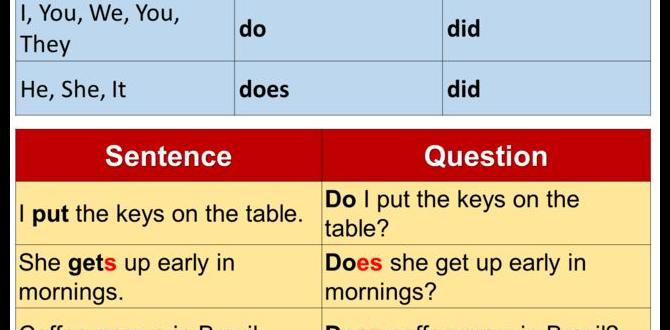

Definition and purpose of blade guides in bandsaws. Importance of proper adjustment for performance and safety.Blade guides are small but important parts of bandsaws. They help keep the blade straight and steady while cutting. Good blade guides let you make clean cuts by supporting the blade from the sides. Proper adjustment of these guides is vital. It improves how well the saw works and keeps you safe from accidents.

- Blade guides hold the blade in place.

- They ensure accurate cutting.

- Properly adjusted guides keep the blade from bending.

- They help avoid injuries by preventing blade jams.

Why are blade guides important?

Well-adjusted blade guides improve performance and safety. Companies report that proper guide adjustment can increase cutting accuracy by up to 30%.Tools Required for Adjustment

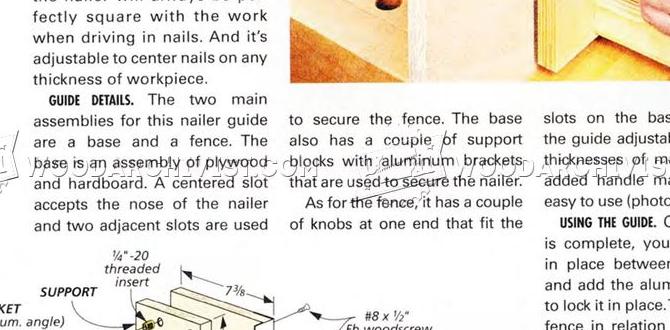

Essential tools needed for adjusting blade guides. Recommended brands and models for best results.To adjust blade guides, you’ll need the right tools. Essential items include a wrench, a screwdriver, and feeler gauges. These tools help ensure your blade runs smoothly. Some popular brands like Wera for screwdrivers and Parkinson for wrenches come highly recommended. Sure, your toolbox might look like a wildlife habitat with all that chaos, but with the right tools, you’ll tame that wild bandsaw in no time!

| Tool | Recommended Brand |

|---|---|

| Wrench | Parkinson |

| Screwdriver | Wera |

| Feeler Gauge | Mitutoyo |

Step-by-Step Guide to Adjusting Blade Guides

Detailed instructions for different types of blade guides. Tips for ensuring accuracy during the adjustment process.Adjusting blade guides on bandsaws sounds tricky, but it’s as easy as pie (or at least a cookie). Start by checking if your guides are correctly positioned for the blade type. There are different guides like roller, block, and polymer. Ensure they are close to the blade, about 1/16 inch, without touching it. This keeps the blade steady and happy! For accuracy, try to check your adjustments with a ruler or a feeler gauge. Remember, a wobbly blade means you might end up with wonky cuts, and nobody wants that! Just think of it this way: a well-adjusted blade is like a jazz musician hitting all the right notes!

| Blade Guide Type | Adjustment Tip |

|---|---|

| Roller Guides | Position close but not touching for smooth moves. |

| Block Guides | Keep them snug to prevent side movement. |

| Polymer Guides | Adjust just enough to maintain a steady rhythm. |

Common Issues with Blade Guides

Signs that blade guides may need adjustment. Troubleshooting tips for common problems.Have you noticed your cuts getting rougher? Maybe your bandsaw is trying to tell you something. If your blade is wobbling or making funny noises, it might need a little TLC. Here are some signs to watch for: unsteady cuts, excessive noise, or a burning smell. Yes, that smell means something is off, and no, it isn’t cooking popcorn!

| Signs | Action |

|---|---|

| Wobbly blade | Check guide alignment |

| Burning smell | Adjust tension or feed rate |

| Uneven cuts | Inspect and adjust guides |

For better cuts, regularly check your guides. Adjust them until they’re just snug. If they’re too tight, your blade might protest. So, keep an eye on these signs to make your bandsaw happy!

Maintenance Tips for Blade Guides

Routine maintenance practices to extend lifespan. How to clean and lubricate blade guides effectively.To keep blade guides in top shape, follow these simple maintenance tips. Regular cleaning and lubrication can help them last longer. Dust and wood shavings can build up, so check the guides often. Wipe them with a soft cloth and apply lube. This keeps everything moving smoothly.

- Clean guides weekly to remove debris.

- Use light oil or a silicone spray for lubrication.

- Inspect for any wear and replace parts as needed.

How to maintain blade guides?

Check the guides regularly for dirt. Clean them with a soft cloth. Apply lubricant to keep them moving freely.

By taking care of your blade guides, you can make your bandsaw work better and last longer. A little maintenance goes a long way!

Impact of Proper Adjustment on Cutting Performance

Effects on cut quality, accuracy, and efficiency. Comparisons between properly adjusted vs. misaligned guides.Proper adjustment of blade guides on bandsaws is crucial for cutting performance. It affects three main areas: cut quality, accuracy, and efficiency. When guides are aligned correctly, cuts are smooth and precise. However, misaligned guides can lead to rough edges and inaccurate cuts. This not only wastes materials but also time. Here’s a quick look at the differences:

- Cut Quality: Smooth with proper guides, rough with misaligned ones.

- Accuracy: Exact measurements with adjustment, off by inches without.

- Efficiency: Faster cutting with aligned guides, slower with misalignment.

In short, keeping guides adjusted means better work and less hassle.

Why is proper adjustment important?

Proper adjustment ensures precise cuts, reduces waste, and boosts production speed.

Advanced Techniques for Experienced Users

Techniques for finetuning blade guides for specific materials. Customizations and modifications for specialized applications.Fine-tuning blade guides can improve your bandsaw’s performance. Different materials need different settings. You might want to adjust guides for thin or thick wood, metal, or plastic. Each can benefit from specific measurements. Try these tips:

- Use tight tolerances for small cuts.

- Widen gaps for thicker materials to reduce friction.

- Monitor blade wear and adjust regularly.

- Add custom blocks for special materials.

These customizations can greatly enhance your cutting precision.

How do I optimize bandsaw settings for different materials?

Adjust the blade guides according to the material thickness to ensure better cuts and reduce waste.

Frequently Asked Questions About Blade Guide Adjustment

Answers to common queries related to blade guide adjustment. Expert tips and resources for further learning.Many people have questions about adjusting blade guides on bandsaws. Here are some common ones:

How often should I check the blade guides?

It’s good to check the blade guides before each use. This ensures safety and accuracy when cutting.

What tools do I need for adjustment?

You’ll likely need a hex key or screwdriver. These tools help to tighten or loosen the guide settings smoothly.

Are there any expert tips for this process?

- Keep the guides clean. Dirt can affect cutting.

- Adjust for blade width. This leads to better performance.

- Follow the manufacturer’s guide. It is helpful for specific settings.

For more about adjusting blade guides, check out online videos and tutorials. They provide great visuals!

Conclusion

In summary, adjusting blade guides on bandsaws is crucial for smooth cuts. Proper adjustments help keep the blade straight and reduce wear. You should always check the guides before starting your project. Experiment with settings to find what works best for you. For more tips, consider reading guides or watching videos online. Happy woodworking!FAQs

What Are The Signs That Indicate The Need To Adjust The Blade Guides On A Bandsaw?You might need to adjust the blade guides on a bandsaw if the blade keeps wandering off center. If you notice rough cuts or uneven edges, that’s another sign. Also, if the blade makes loud noises while cutting, it could mean something’s wrong. Finally, if the blade moves too much when touched, it’s time to check the guides.

How Do You Properly Set The Upper And Lower Blade Guides To Ensure Optimal Cutting Performance?To set the upper and lower blade guides, first, you need to find the blade. Look for the small wheels at the top and bottom of the saw. Adjust the guides so they are close to the blade but not touching it. This helps the blade move smoothly. Tighten the guides to keep them in place, and check your work to make sure everything is secure.

What Tools Are Typically Required For Adjusting The Blade Guides On A Bandsaw?To adjust the blade guides on a bandsaw, you usually need some simple tools. You often need an Allen wrench or hex key to loosen the screws. A screwdriver can also help with some types of adjustments. Sometimes, a measuring tape is useful to check the guide’s position. Always make sure you turn off the saw first for safety!

How Can Improper Blade Guide Adjustments Affect The Quality Of Cuts And The Lifespan Of The Bandsaw Blade?If the blade guide on a bandsaw is not set correctly, it can cause bad cuts. The blade might wobble and make uneven shapes. This also makes the blade wear out faster. When the blade wears out quickly, you need to replace it more often, which costs money. So, keeping the blade guide right helps your cuts look better and your blade last longer.

Are There Different Adjustment Techniques For Various Types Of Bandsaw Blades, Such As Carbide-Tipped Versus Bi-Metal Blades?Yes, there are different ways to adjust bandsaw blades. Carbide-tipped blades and bi-metal blades need different settings. Carbide blades are really hard and cut tough materials, so they might need tighter adjustments. Bi-metal blades are flexible and can bend, so you should adjust them differently. Always check your blade type before you make changes!