Yes, you can use stainless steel nails for many outdoor and marine projects! They offer superior rust resistance compared to galvanized or regular steel nails, making them ideal for preventing unsightly stains and ensuring long-term durability in wet or corrosive environments.

Are you getting ready for an outdoor woodworking project, maybe a deck, fence, or a garden planter? You’ve probably heard a lot about different types of nails and what works best where. One question that often pops up is about using stainless steel nails. Maybe you’ve seen them and wondered if they’re overkill, or if they’re even the right choice for your DIY task. It’s easy to get a bit confused with all the options out there!

Don’t worry; choosing the right fastener can feel like a puzzle, but I’m here to guide you. We’ll break down exactly when and why you’d want to use stainless steel nails, how they stack up against other types, and what to look for to make sure your project not only looks great but lasts for years. Let’s get those projects nailed down right!

Table of Contents

What Are Stainless Steel Nails and Why Are They Special?

Stainless steel nails are fasteners made from an alloy of iron, chromium, and often nickel. The key ingredient here is chromium. When chromium is exposed to air, it forms a thin, invisible, and passive layer of chromium oxide on the surface of the nail. This oxide layer is incredibly resistant to corrosion, meaning it essentially heals itself if scratched and protects the steel underneath from rusting.

This makes stainless steel nails a fantastic choice for projects exposed to moisture or harsh weather. Think about it: your deck boards are constantly getting rained on, your fence stands guard against all sorts of elements, and anything near the coast is dealing with salty air. Regular nails would quickly succumb to rust, leaving brown streaks and weakening the entire structure. Stainless steel nails fight back against this degradation.

When Should You Absolutely Use Stainless Steel Nails?

The short answer? When you want your project to last and look good, especially when it’s outdoors or in a damp environment. Here’s a more detailed look at the prime scenarios:

Outdoor Projects

This is the big one. Any woodworking project that lives outside is a prime candidate for stainless steel nails:

Decks: Your deck is exposed to rain, sun, and humidity. Stainless steel nails prevent rust stains that can bloom on your deck boards and keep the fasteners from corroding over time.

Fences: Fences are constantly battling the elements. Using stainless steel ensures your fence stays strong and doesn’t develop unsightly rust lines running down the pickets.

Pergolas and Gazebos: These structures are architectural features meant to be enjoyed outdoors. Stainless fasteners contribute to their aesthetic appeal and structural integrity.

Garden Beds and Outdoor Furniture: If you’re building raised garden beds or sturdy outdoor seating, stainless nails will hold strong and resist the moisture from soil and weather.

Trellises and Arbors: These decorative elements, often placed in gardens, benefit from the rust-proof nature of stainless steel.

Marine and Coastal Applications

If you live near the ocean or are building something that will be in or around water, stainless steel is practically a requirement:

Docks and Piers: These are submerged or constantly splashed by saltwater, which is highly corrosive. Stainless steel is one of the few fastener materials that can withstand this.

Boats and Marine Structures: Any part of a boat or dock that isn’t specifically designed for submersion in saltwater will benefit greatly from stainless fasteners.

Coastal Homes: Even on homes in coastal areas, where salt spray can travel inland, using stainless steel for exterior trim, siding, or railings is a wise investment.

Projects Using Certain Woods

Some types of wood, particularly tannin-rich woods like cedar, redwood, or oak, can react with fasteners made of less noble metals. This reaction can cause staining, even indoors, and is significantly accelerated by moisture. Stainless steel nails are the best choice to pair with these woods to avoid a “bleeding” effect.

High-Moisture Interiors

While less common for nails, if you’re working on a project in a very humid indoor environment, like a steamy bathroom or a laundry room, stainless steel could be a consideration to prevent premature corrosion.

Stainless Steel Nails vs. Other Types: A Comparison

To really understand why stainless steel is great, let’s see how it compares to the other common nail types you’ll encounter.

Common Nail Types

Bright (Steel) Nails: These are just plain steel nails. They are the cheapest option but offer virtually no corrosion resistance. They are only suitable for temporary work or projects that will be completely protected from moisture.

Galvanized Nails: These are steel nails coated with a layer of zinc. The zinc acts as a sacrificial barrier, corroding before the steel.

Electro-Galvanized (EG): Has a thinner zinc coating. Offers basic protection and is suitable for some interior applications or very protected exterior use.

Hot-Dip Galvanized (HDG): Has a thicker, more robust zinc coating. This is the standard for most exterior applications where corrosion resistance is needed but stainless steel isn’t specified. For best results, look for nails meeting ASTM A153 standards.

Stainless Steel Nails: As we’ve discussed, these are made from a corrosion-resistant alloy. They offer the highest level of protection against rust.

Table: Nail Types and Their Best Uses

| Nail Type | Material | Corrosion Resistance | Typical Use Cases | Cost (Relative) | Professional Recommendation |

| :——————— | :——————- | :——————- | :———————————————————————————– | :————– | :————————————————————————————————————————————————————————————————1 |

| Bright (Steel) Nails | Steel | Very Poor | Temporary framing, interior applications completely protected from moisture | $ | Avoid for any visible projects or those exposed to humidity. Can lead to rust stains and structural failure. |

| Electro-Galvanized (EG) | Steel with Zinc Coat | Fair to Good | Interior trim, furniture, light exterior trim where aesthetics are critical and moisture is minimal | $$ | Suitable for non-structural interior work or very protected exterior trim. May not last long on decks or fences in humid climates. |

| Hot-Dip Galvanized (HDG) | Steel with Thick Zinc Coat | Good to Very Good | Decks, fences, exterior framing, siding, treated lumber applications | $$$ | The go-to for most general exterior wood construction. Essential when working with pressure-treated lumber that can be corrosive to less protected nails. Look for ASTM A153 rated nails. |

| Stainless Steel Nails | Stainless Steel Alloy | Excellent | Decks, fences, docks, marine applications, coastal areas, cedar/redwood/oak projects | $$$$ | The premium choice for maximum longevity and aesthetic preservation in harsh environments. Essential for saltwater exposure and highly reactive woods to prevent staining and corrosion. |

Note: Costs are relative and can vary based on size, quantity, and brand.

Why Hot-Dip Galvanized (HDG) Isn’t Always Enough

While hot-dip galvanized nails are a solid choice for most outdoor projects, they aren’t foolproof. The zinc coating will eventually wear away, especially in highly corrosive environments like coastal areas or when used with certain types of treated lumber (ACQ, copper-based treatments can be corrosive).

For instance, the U.S. Department of Agriculture (USDA) Forest Products Laboratory recommends stainless steel or silicon bronze fasteners for decks and other outdoor structures where longevity and appearance are paramount, especially when using newer wood preservation treatments that can be more aggressive.

Types of Stainless Steel Nails

Just like other nail types, stainless steel comes in various forms and is used for different purposes.

Common Stainless Steel Nail Types by Head Style:

Common/Box Nails: Feature a larger head to provide good holding power. Ideal for general construction where strength and function are key.

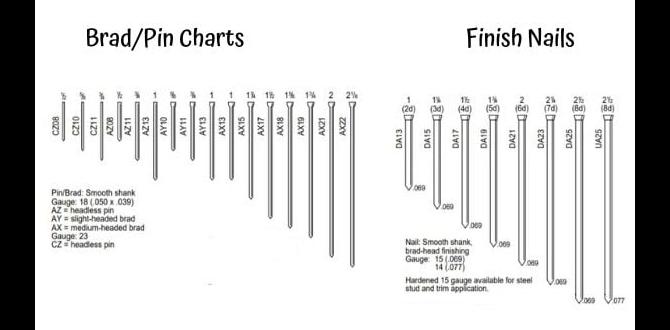

Finishing Nails: Have a small, discreet head that can be easily sunk below the wood surface and filled for a clean look. Great for trim work, molding, and cabinetry.

Brad Nails: Similar to finishing nails but much smaller and thinner. Used for delicate trim and craft projects.

Annular Ring/Ring Shank Nails: Have grooves or rings around the shank for superior holding power. Excellent for applications where significant pulling forces are expected, like subflooring or siding.

Duplex Head Nails: Have two heads, one above the other. The top head allows the nail to be easily pulled out, making them perfect for temporary structures like concrete forms or scaffolding.

Stainless Steel Grades

Not all stainless steel is created equal. For fasteners, you’ll most commonly see two grades:

304 Stainless Steel: This is the most common grade. It’s durable, highly corrosion-resistant, and generally suitable for most outdoor applications that aren’t directly exposed to saltwater. It offers excellent resistance to many chemicals and atmospheric conditions.

316 Stainless Steel: This grade contains molybdenum, which significantly enhances its resistance to pitting and corrosion from chlorides, especially saltwater. If you’re building a dock, a boat, or live in a harsh marine environment, 316 stainless steel is the premium choice. It’s often referred to as “marine grade.”

How to Choose the Right Stainless Steel Nail

When you’re ready to buy, keep these factors in mind:

1. Project Type: Is it a deck, fence, trim, or something else? This will dictate the head style and shank type.

2. Environment: Will it be exposed to rain, humidity, salt spray, or corrosive chemicals? This determines the grade of stainless steel needed (304 vs. 316).

3. Wood Type: Are you using cedar, redwood, or pressure-treated lumber? These can influence your choice as mentioned earlier.

4. Holding Power: Does the project require strong holding power (e.g., structural elements) or is appearance more critical (e.g., trim)?

5. Tool Compatibility: Many stainless steel nails are designed for use with nail guns. Ensure the nail size and type match your nailer’s specifications.

Using Stainless Steel Nails with Nail Guns

Many DIYers opt for nail guns for efficiency and speed. If you plan to use a nail gun with stainless steel nails, here’s what you need to know:

Hardness: Stainless steel is harder than regular steel. This means it requires a powerful nail gun to drive them effectively.

Compatibility: Check your nail gun’s manual. Some lower-powered or older pneumatic nail guns might struggle to drive stainless steel nails, especially longer ones, fully into hardwood. You might need a higher PSI (pounds per square inch) air compressor or a more robust nail gun.

Nail Gun Oil: Keep your nail gun well-lubricated. The added friction from driving harder stainless steel nails can increase wear and tear.

Jamming: Because they are harder, stainless steel nails can occasionally cause jams if the gun isn’t powerful enough or if the nails are slightly out of spec. Regularly cleaning and maintaining your nail gun can help prevent this.

Collation: Stainless steel nails come collated (glued or wired together) for use in nail guns. Ensure you get the correct collation type (e.g., angled, straight) that matches your nail gun.

For detailed information on pneumatic nailer maintenance, resources like the Occupational Safety and Health Administration (OSHA) offer safety and best practice guidelines that can indirectly inform tool care: You can find useful safety and general operational information on the OSHA website.

Pros and Cons of Stainless Steel Nails

Like any material, stainless steel nails have their advantages and disadvantages.

Pros:

Superior Corrosion Resistance: This is their biggest selling point. They resist rust and staining exceptionally well, maintaining the appearance of your project.

Durability: They are strong and less likely to bend or break than softer metals.

Longevity: Projects built with stainless steel fasteners tend to last much longer, especially in challenging environments.

Aesthetic Appeal: They maintain their look over time, preventing unsightly rust streaks that can ruin the finish of nice wood.

Wood Compatibility: Excellent choice for tannin-rich woods like cedar and redwood, preventing staining.

Good for Treated Lumber: They stand up well to the chemicals in modern pressure-treated lumber.

Cons:

Cost: Stainless steel nails are significantly more expensive than galvanized or bright steel nails. This can add up for large projects.

Hardness: Can be harder to drive by hand with a hammer, potentially requiring more effort or a specialized hammer.

Nail Gun Strain: May require more powerful nail guns and higher air pressure, potentially causing more wear on the tool.

Availability: While increasingly common, specific sizes or grades (like 316) might be harder to find at general hardware stores compared to galvanized options.

DIY Project Spotlight: Building a Cedar Birdhouse

Let’s put this knowledge to use with a simple project idea: a cedar birdhouse. Cedar is naturally resistant to rot and insects, making it perfect for outdoor use. But because it’s a tannin-rich wood, it can stain other metals.

Tools and Materials:

Cedar lumber (½ inch or ¾ inch thick)

Stainless Steel Finishing Nails (e.g., 1 ¼ inch)

Wood glue (exterior grade)

Saw (hand saw or power saw)

Measuring tape

Pencil

Safety glasses

Hammer (or a brad nailer for convenience)

Sandpaper

Steps:

1. Cut Your Pieces: Based on a simple birdhouse plan (easily found online!), carefully measure and cut your cedar pieces for the front, back, sides, bottom, and roof.

2. Assemble the Walls: Apply a thin bead of exterior wood glue to the edges where the side pieces will meet the front and back.

3. Nail Them Together: Using your stainless steel finishing nails, secure the side pieces to the front and back. If using a hammer, drive the nails carefully. If using a brad nailer, ensure your stainless steel brad nails are compatible and set the depth correctly. The small heads of finishing or brad nails will be easy to hide.

4. Attach the Bottom: Glue and nail the bottom piece into place, making sure to use enough nails for a secure hold.

5. Add the Roof: Glue and nail the roof pieces. You might want one roof piece to slightly overlap the other for better water runoff.

6. Finishing Touches: Once the glue is dry, you can lightly sand any rough edges. No need for paint or stain as cedar has a beautiful natural color and the stainless nails won’t rust.

This simple project highlights how ideal stainless steel nails are for working with beautiful, naturally resistant woods like cedar.

Safety First!

No matter what fasteners you choose, safety is always paramount.

Eye Protection: Always wear safety glasses when hammering nails or using a nail gun. Debris can fly unexpectedly.

Nail Gun Safety: If using a nail gun, always read and follow the manufacturer’s instructions. Keep your fingers away from the trigger and muzzle. Never point it at anyone. For more detailed safety information, check out resources from tool manufacturers or safety organizations.

* Hammering: Ensure you have a firm grip on the hammer and are mindful of where your fingers are. Swing with control.

Frequently Asked Questions (FAQ)

Q1: Are stainless steel nails overkill for a simple garden bench that will be painted?

While painting can offer some protection, using stainless steel nails for an outdoor garden bench is still a wise choice, especially if the bench will be exposed to the elements. Even with paint, moisture can eventually find its way to the fasteners, leading to rust that can show through the paint as unsightly bleeds. Stainless steel gives you long-term peace of mind and ensures the bench remains structurally sound and visually appealing for years.

Q2: Can I use stainless steel nails with pressure-treated lumber?

Yes, absolutely! In fact, it’s highly recommended. Modern pressure-treated lumber, particularly that treated with alkaline copper quaternary (ACQ) or other copper-based preservatives, can be corrosive to standard galvanized fasteners over time. Stainless steel nails, especially grade 304 or 316, are far more resistant to this corrosion and the staining that can result, ensuring a longer lifespan for your project.

Q3: How can I tell if a nail is truly stainless steel?

The best way is to check the packaging. Reputable manufacturers will clearly label their nails as “Stainless Steel.” You may also see a grade specified, like “304” or “316.” Visually, stainless steel nails often have a brighter, more silvery finish compared to galvanized nails, which can appear duller or have a slightly mottled appearance from the zinc coating. If you’re unsure, a magnet test can offer a clue: most stainless steels are non-magnetic or only weakly magnetic, though some grades can be magnetic. However, packaging information is the most reliable indicator.

Q4: Do stainless steel nails rust at all?

While stainless steel is highly resistant to rust and corrosion, it is not entirely immune, especially in extreme conditions. Grade 304 stainless steel can corrode in environments with high chloride concentrations, like direct, prolonged saltwater exposure. Grade 316 stainless steel is much more resistant to saltwater due to its molybdenum content. However, for typical outdoor applications like decks and fences in most climates, both grades offer excellent performance and vastly superior protection compared to other nail types.

Q5: Is it harder to drive stainless steel nails by hand than regular nails?

Yes, stainless steel is a harder metal than standard steel, which means driving stainless steel nails by hand with a hammer will generally require more force and effort. You might find they don’t penetrate