Have you ever wondered how to measure lumber easily? If you love woodworking or just enjoy building things, you’re in the right place! The wood source board foot calculator can help you figure out how much wood you need for your projects.

Imagine planning a new bookshelf or a treehouse. You’ve got your ideas sorted but need to know how much wood to buy. This tool takes the guesswork out. It’s like having a magic calculator for wood!

Did you know that a board foot is a way to measure wood? It’s equal to a piece that is one foot long, one foot wide, and one inch thick. Sounds simple, right? Understanding this will help you save money and avoid waste.

In this article, we’ll explore the wood source board foot calculator. You’ll discover how to use it and why it’s so handy. Ready to dive into the world of wood measurements? Let’s get started!

Table of Contents

Wood Source Board Foot Calculator: Your Ultimate Tool For Lumber Measurement

The Wood Source Board Foot Calculator is a handy tool for woodworkers and DIY enthusiasts. It helps determine the exact amount of lumber needed for a project. By inputting dimensions, users can quickly figure out board feet, saving time and money. Did you know one board foot equals 144 cubic inches? This calculator ensures you buy just the right amount of wood, preventing waste and keeping costs down. Efficient planning leads to better projects!

Understanding Board Feet

Definition of board foot and its importance in lumber measurement. Explanation of how board feet are calculated.

Board feet are a way to measure lumber. Think of it as the “sneaky” unit used by carpenters. One board foot equals a piece of lumber that is 1 foot long, 1 foot wide, and 1 inch thick. It’s important because it helps in pricing and ordering wood. To calculate board feet, use this simple formula: Length (inches) x Width (inches) x Thickness (inches) / 144. That’s right! You divide by 144! Just how many math problems do we need in woodwork?

| Measurement | Example |

|---|---|

| Length (inches) | 12 |

| Width (inches) | 6 |

| Thickness (inches) | 1 |

This gives us 12 x 6 x 1 divided by 144, which equals 0.5 board feet! Easy peasy, right? So, whether you’re fixing a chair or building a treehouse, knowing about board feet can save you time and money! And who doesn’t like saving a few bucks?

How to Use the Wood Source Board Foot Calculator

Stepbystep instructions on inputting measurements into the calculator. Tips for ensuring accurate measurements for calculation. Using a wood source board foot calculator can feel like magic! Start by measuring the length, width, and thickness of your wood piece in inches. Next, simply plug those numbers into the calculator. Make sure to double-check your measurements; a tiny error can turn a grand plan into a plank! Remember, measure twice, cut once—and don’t confuse a ruler with a snack!

| Measurement | Input (in inches) |

|---|---|

| Length | ____ |

| Width | ____ |

| Thickness | ____ |

Accurate numbers lead to accurate results! So, take your time, and avoid using a broken tape measure. Happy calculating!

Factors Affecting Board Foot Calculation

Discussion on different types of wood and how they impact board foot calculations. Importance of wood thickness, width, and length in measurement.

Different types of wood can change the board foot calculation. Each species has its unique density and weight. Some woods are heavier and denser, which can affect the total volume. Important factors are:

- Thickness: Thicker wood means more board feet.

- Width: Wider boards provide more surface area.

- Length: Longer pieces add to the total calculation.

Understanding these elements helps ensure accurate measurements.

How does wood type affect board foot calculation?

Wood type impacts weight and density, which changes board foot calculations. Different woods require different considerations for accurate results.

The Benefits of Using a Board Foot Calculator

Costefficiency in lumber purchasing and project budgeting. Timesaving in calculations compared to manual methods. Using a board foot calculator can save you money and time. First, it’s super cost-efficient. It helps you buy just the right amount of lumber, so you won’t end up with a pile of extra wood. Who needs a new shelf for that? Second, it’s a serious time-saver! No one likes scratching their heads over lumber math. A calculator does it in seconds. And let’s be honest, we’d rather build than add! Here’s a quick look at how it helps:

| Benefits | Details |

|---|---|

| Cost Efficiency | Avoids extra lumber cost. |

| Time Saving | Calculates quickly and accurately. |

Comparing Online Board Foot Calculators

Review of popular online board foot calculators and their features. Pros and cons of using various calculators available in the market.

Many people use online board foot calculators to make their wood projects easier. Some popular tools include the Calculators Hub and the Woodworkers Guild of America. Each has different features. For example, some calculators let you input wood thickness, width, and length, while others offer volume estimates too. However, not all calculators are created equal!

If you want to avoid hiccups, check the pros and cons:

| Calculator | Pros | Cons |

|---|---|---|

| Calculators Hub | Easy to use, detailed calculations | Ads can be distracting |

| Woodworkers Guild | Great for beginners, clear layout | Limited advanced features |

Using the right calculator can help you avoid counting your wood like sheep! With a little practice, you’ll be measuring like a pro in no time! Happy woodworking!

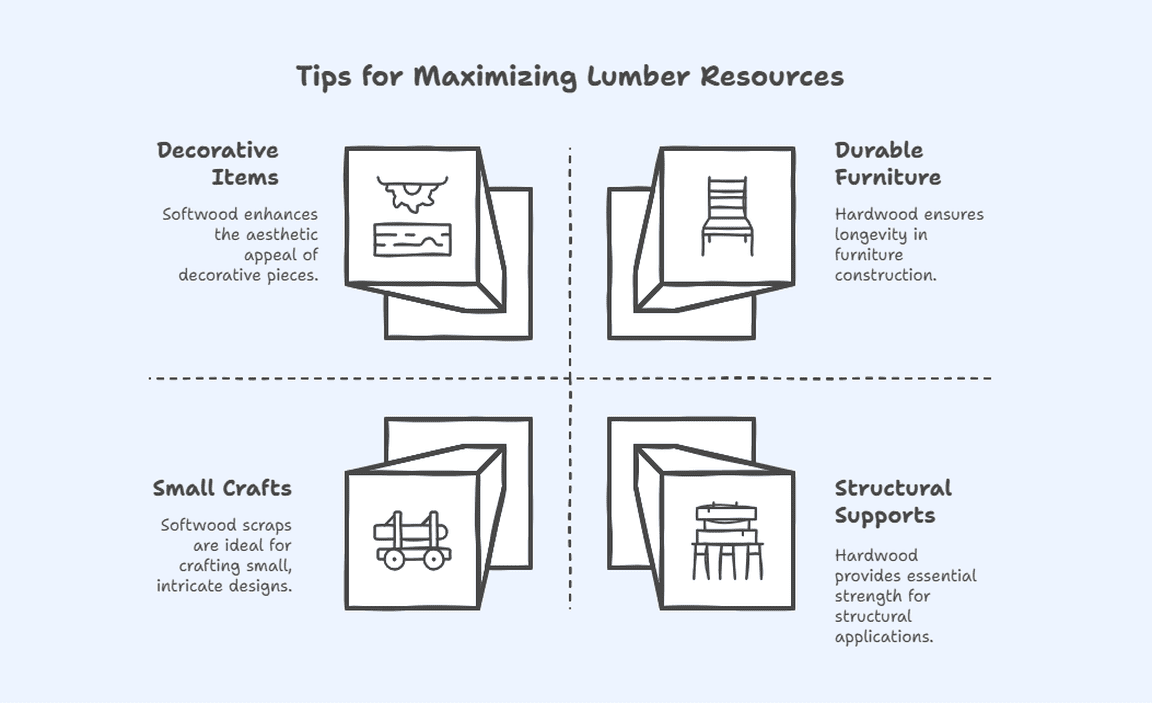

Tips for Maximizing Lumber Resources

Advice on optimizing cuts and reducing waste. Strategies for selecting the right type of wood for your projects. To make the most of your lumber, careful planning is key. Optimize your cuts by visualizing the wood layout first. This helps in reducing waste. Choose the right type of wood for your project. Each type has different strengths. Softwoods are great for furniture. Hardwoods are perfect for durable items. Here are some tips:

- Measure twice, cut once.

- Use scraps for smaller projects.

- Consider wood grain direction for strength.

Smart choices save resources and money!

What is the best way to reduce waste when cutting wood?

Plan your cuts carefully. This means thinking about how each piece fits together. A good plan leads to less scrap.

FAQs About Board Foot Measurement

Answers to common questions regarding board foot measurement and calculators. Clarifications on misconceptions related to lumber size and pricing.

Many people wonder about board foot measurements. First, what is a board foot? It’s a unit that shows the volume of lumber. You can measure it by multiplying length, width, and thickness (in inches) and then dividing by 144. Simple, right? Also, remember, not all lumber is priced the same. Pricing can depend on wood type, size, and market demand. So don’t go thinking every board foot is equal; it’s like comparing apples to oranges! And, if you’re using a calculator, make sure to double-check the numbers, or you might end up buying a tree instead of a board!

| Common Questions | Answers |

|---|---|

| What is a board foot? | A unit of lumber volume, calculated by dimensions. |

| How is it measured? | Length x Width x Thickness ÷ 144. |

| Why does lumber cost vary? | Different types and market demand impact pricing. |

Conclusion

In conclusion, a Wood Source Board Foot Calculator helps you estimate lumber volume easily. You input the dimensions, and it does the math for you. Knowing this can save you time and money when buying wood. To get started, try finding a calculator online and practice using it with your own measurements. Happy building!

FAQs

What Is A Board Foot And How Is It Used In Measuring Lumber?

A board foot is a way to measure wood. It’s the size of a board that is 1 foot long, 1 foot wide, and 1 inch thick. We use board feet to know how much wood we need for projects. This helps us buy the right amount when working with lumber.

How Do You Calculate The Volume Of A Piece Of Lumber In Board Feet?

To find the volume of lumber in board feet, first measure the length, width, and thickness of the wood in inches. Then, multiply these three numbers together. After that, divide the result by 144. This gives you the volume in board feet. Remember, one board foot is equal to a piece that is one foot long, one foot wide, and one inch thick.

What Factors Influence The Price Of Lumber When Using Board Feet As A Measurement?

The price of lumber in board feet depends on a few important things. First, the supply and demand matter. If more people want lumber than there is available, the price goes up. Second, the type of wood affects the cost. Rare woods usually cost more than common ones. Finally, weather events, like storms or fires, can reduce the amount of wood available, making prices higher.

Can You Explain The Difference Between Nominal Size And Actual Size Of Lumber When Calculating Board Feet?

Nominal size is the name we give to lumber, like 2×4 inches. But the actual size is smaller, usually about 1.5×3.5 inches. This happens because the wood is cut and shaped. When we calculate board feet, we use the actual size to get the real amount of wood. So, remember, nominal is the name and actual is the true size!

Are There Any Online Tools Or Calculators Available For Quickly Determining Board Feet From Dimensions Provided?

Yes, there are online tools to help you calculate board feet. You just enter the measurements of your wood. These tools do the math for you quickly. You can find them easily by searching online for “board feet calculator.” They’re simple and free to use!

Resource:

Lumber Grading Standards: https://www.awc.org/codes-standards/publications/d510

Wood Density and Properties: https://www.wood-database.com/wood-articles/density-of-wood-species/

Tips on Reducing Wood Waste: https://www.finewoodworking.com/2008/06/18/tips-for-getting-the-most-out-of-your-lumber

Beginner’s Guide to Woodworking: https://www.popularwoodworking.com/techniques/beginners-guide-to-woodworking-tools-and-skills/