Have you ever wondered how fine furniture makers create smooth, sloped edges on their pieces? This is where bevel cutting comes into play. It is a technique that many people may not know about, yet it is essential for making precise cuts. Imagine crafting a picture frame with sharp, clean angles. It’s not just about looks; it also ensures that everything fits perfectly.

Bevel cutting involves tilting a cutting tool at an angle. This might sound tricky, but it allows for stunning designs and strong connections in woodworking and metalworking. Did you know that even the best chefs use bevel cutting to create perfect slices in their culinary creations? It’s true! Whether you are a hobbyist or a professional, learning about bevel cutting can boost your skills.

In this essential guide, we will explore what bevel cutting is and how it can transform your projects. You’ll discover tips and tricks to master this skill and impress your friends. Are you ready to dive in and learn about precision cuts? Let’s get started!

Table of Contents

What Is Bevel Cutting?: Essential Guide For Precision Cuts

What is Bevel Cutting?: Essential Guide for Precision Cuts

Bevel cutting is a technique for making angled cuts on materials like wood or metal. This method creates a slanted edge, making joints stronger and more attractive. Ever wondered how carpenters make perfect angles? They often use bevel cuts! This guide explains tools, techniques, and tips for achieving precise bevel cuts. Whether you’re a beginner or a seasoned pro, understanding bevel cutting can elevate your craft and improve your projects. Get ready to transform your cutting skills!Understanding Bevel Cutting

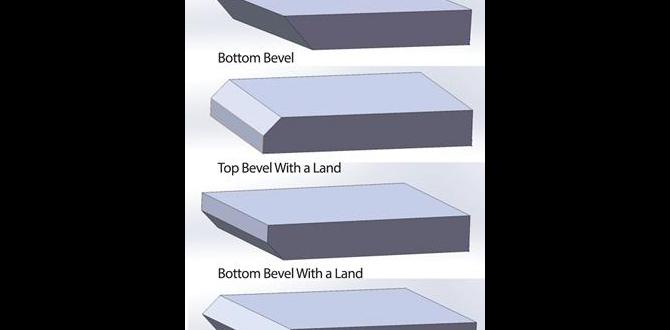

Definition of bevel cutting and its significance in precision work. Types of bevel cuts and their applications in various industries.Bevel cutting means slicing at an angle, not straight down. This method is important for making precise, clean cuts. It improves the fit and look of joined pieces. Common types of bevel cuts include:

- Simple bevels: used in furniture making.

- Compound bevels: important in carpentry and molding.

- Miters: essential for frames and trim work.

These cuts are vital in many industries like construction and crafts, improving both function and appearance.

What are the benefits of bevel cutting?

The main benefits of bevel cutting are accuracy and improved joint strength. These cuts help pieces fit better and look nicer, which is key in many projects.

Techniques for Precise Bevel Cutting

Stepbystep guide for achieving accurate bevel cuts. Common mistakes to avoid during the bevel cutting process.To achieve perfect bevel cuts, start with clear measurements. Use a protractor for angles and double-check each one. Don’t be that person who writes “measure once, cut twice” on their wall! Set your saw at the correct angle, and keep a steady hand while cutting. Avoid common mistakes like rushing or misreading measurements—your future self will thank you! Remember, even the best carpenters were once just learning; practice makes it perfect.

| Common Mistakes | How to Avoid |

|---|---|

| Wrong angle settings | Check twice, cut once! |

| Rushing cuts | Take your time, enjoy the process. |

| Not securing the material | Clamp it down, don’t let it dance! |

Applications of Bevel Cutting

Uses in woodworking, metalworking, and other crafting sectors. Realworld examples highlighting the importance of bevel cuts.Bevel cutting is not just a fancy term; it shows up everywhere! In woodworking, it helps make smooth edges on tables and cabinets. Imagine that cute bookshelf with slanted edges—thank bevel cuts for its charm! In metalworking, bevel cuts are key for welding. They create strong joints. For crafts, artists use bevels to add flair to their designs. Whether you are building a treehouse or crafting a unique lamp, bevel cuts make everything better!

| Field | Example |

|---|---|

| Woodworking | Smooth edges for furniture |

| Metalworking | Strong welds on metal pieces |

| Crafting | Decorative items with style |

Bevel vs. Miter Cuts: Key Differences

Comparison of bevel cuts and miter cuts. Situations where one cut is preferable over the other.Bevel cuts and miter cuts may sound like fancy dance moves, but they are actually types of cuts used in woodworking. Bevel cuts are angled along the thickness of the wood, while miter cuts are angled on the end. Think of it as a diagonal haircut versus a straight one! Bevel cuts are great for joining pieces like crown molding, while miter cuts shine when making frames or corners. Knowing these differences can save you from some seriously awkward assembly moments!

| Cut Type | Angle | Best Use |

|---|---|---|

| Bevel Cut | Thickness | Crown molding |

| Miter Cut | End | Frames |

Safety Considerations in Bevel Cutting

Important safety gear and precautions while bevel cutting. Recommended practices to ensure a safe cutting environment.Safety is very important when bevel cutting. Always wear the right gear to protect yourself. Use goggles to shield your eyes from flying debris. Ear protection helps guard against loud noise, while gloves keep your hands safe. Make sure your work area is clear of clutter. This helps prevent accidents.

- Keep tools sharp to avoid slips.

- Ensure proper lighting for clear visibility.

- Always follow the manufacturer’s instructions.

Taking these precautions can help make bevel cutting safe and enjoyable.

What safety gear is needed for bevel cutting?

For bevel cutting, you need to wear safety goggles, ear protection, and gloves. This gear shields you from injuries while working.

Maintaining Your Bevel Cutting Tools

Tips for maintaining and sharpening tools to ensure precision. Signs that indicate when tools need inspection or replacement.Keeping your bevel cutting tools in top shape is key for good cuts. Here are some tips to help:

- Clean tools after every use. Dirt can damage them.

- Sharpen blades regularly. This ensures they cut well.

- Store tools properly. A dry, safe place helps prevent rust.

Watch for these signs to know when tools need checking:

- Blades are dull and struggle to cut.

- There are visible cracks or chips.

- Handles feel loose or wobbly.

Taking care of your tools means better work every time!

What are the key steps for maintaining bevel cutting tools?

Keep them clean, sharpen them often, and check for damage to ensure precision.

Conclusion

In conclusion, bevel cutting is a valuable technique for making precise angled cuts. We learned it helps create strong joints and adds a nice look to projects. To master bevel cutting, practice with different materials and tools. You can explore more guides and videos to improve your skills. Start experimenting, and enjoy the art of precision cuts!FAQs

What Is Bevel Cutting, And How Does It Differ From Other Cutting Techniques?Bevel cutting is when you cut at an angle instead of straight across. This makes the edges of things slant, like the corners of a picture frame. It’s different from other cuts because those are usually straight lines. If you want a smoother look or fit, bevel cuts are the best choice. You’ll see bevel cuts in woodwork, glass, and metal projects.

What Tools And Equipment Are Commonly Used For Bevel Cutting?For bevel cutting, you can use a few important tools. A miter saw is great for making angled cuts. A table saw also works well for this task. You might need a bevel gauge to measure the angle you want. Finally, a hand saw can help for smaller projects.

How Can You Achieve Precise Bevel Cuts In Various Materials Such As Wood, Metal, And Plastic?To make precise bevel cuts, you can use a few handy tools. A miter saw is great for wood. For metal, a chop saw works well. When cutting plastic, you can use a table saw or a bandsaw. Always measure carefully and mark your cut line before starting. This helps you cut straight and at the right angle!

What Are Some Common Applications And Industries Where Bevel Cutting Is Essential?Bevel cutting is important in many places. We see it in carpentry when making fancy edges on wood. It is also used in metalworking to prepare pieces for welding. In construction, bevel cuts help fit materials together nicely. Plus, it’s used in making glass to create smooth finishes.

What Safety Precautions Should Be Taken When Performing Bevel Cuts To Ensure Accuracy And Prevent Accidents?When making bevel cuts, always wear safety goggles to protect your eyes. Keep your fingers away from the blade to avoid cuts. Make sure your work area is clean and free of clutter. Use a clamp to hold your material steady while you cut. Lastly, double-check your measurements to ensure accuracy before you start cutting.