Quick Summary:

Nail crown molding like a pro with these beginner-friendly tips! Learn about the right tools, precise cuts, and proper nailing techniques to achieve a seamless, professional look without damaging your wood. Get ready to elevate your home’s style!

Hey there, DIYers and woodworkers! Jack Shaffer here from Nailerguy. Ever look at a room with beautiful crown molding and think, “That looks complicated”? You’re not alone. Many folks shy away from installing crown molding because it seems tricky. But let me tell you, with the right approach and a few handy tips, you can absolutely nail this project. We’re going to break it down step-by-step, making it simple and achievable, so you can add that touch of elegance to your home with confidence. Ready to transform your walls?

Table of Contents

Why Crown Molding? A Touch of Class for Your Home

Crown molding, also known as crown trim or cornice molding, is that decorative trim installed at the junction of interior walls and ceilings. It’s like the cherry on top for any room, adding architectural detail, visual interest, and a sense of finished polish. It can make a room feel grander, hide imperfections where the wall meets the ceiling, and really tie a design together. Whether you’re renovating an old home or just want to give a modern space a more sophisticated feel, crown molding is a fantastic way to do it. And guess what? It’s a totally achievable DIY project!

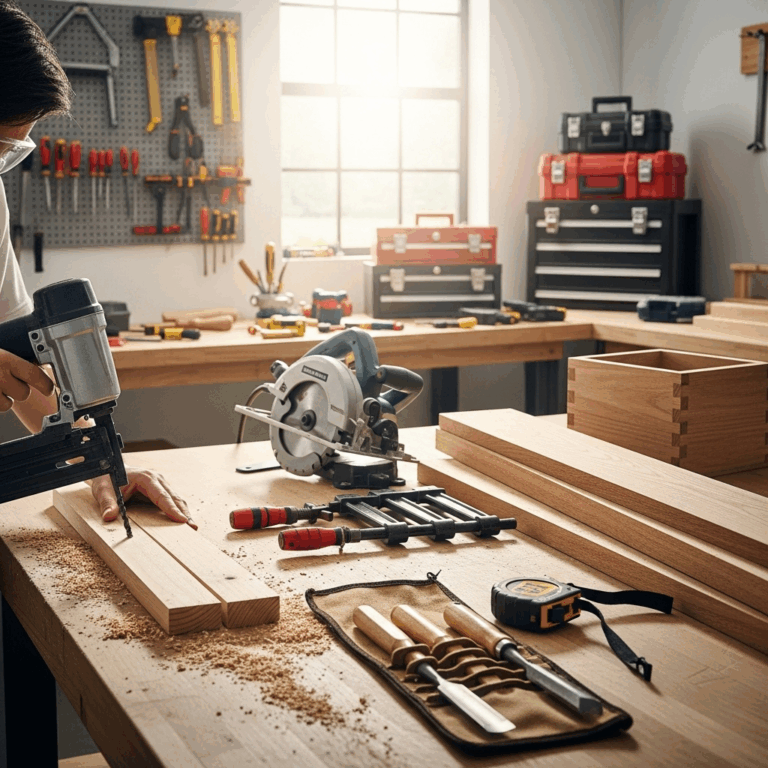

Gathering Your Essential Tools: The Right Gear for the Job

Before we start cutting and nailing, let’s make sure you’ve got the right tools. Having the proper equipment makes all the difference, ensuring accuracy and preventing frustration. Think of this as Jack’s essential toolkit for crown molding success:

- Miter Saw: This is non-negotiable for precise angle cuts. A compound miter saw is even better as it can tilt for angled cuts, which are crucial for crown molding.

- Nail Gun (Brad Nailer or Finish Nailer): A pneumatic or cordless nail gun is your best friend here. It drives nails quickly and consistently, preventing hammer-induced dents and speeding up the process. A 16-gauge finish nailer is generally ideal. If you’re going nail-free for a specific aesthetic or material, consider high-quality construction adhesive, but nailing provides the strongest initial hold.

- Air Compressor & Hose (if using pneumatic nailer): Make sure your compressor has enough CFM (Cubic Feet per Minute) to keep up with your nailer.

- Measuring Tape: Accuracy is key!

- Pencil: For marking measurements and cuts.

- Stud Finder: To locate wall studs for secure fastening.

- Safety Glasses: ALWAYS wear safety glasses when using power tools.

- Gloves: For a better grip and protection.

- Caulk Gun & Paintable Caulk: For filling gaps and imperfections.

- Putty Knife & Wood Filler: For minor repairs and filling nail holes.

- Level: To ensure your molding is straight.

- Coping Saw or Oscillating Multi-Tool (Optional, but recommended for inside corners): For achieving tight, seamless joints on inside corners.

- Chalk Line (Optional): For marking long, straight lines on larger walls.

- Step Ladder or Extension Ladder: Ensure it’s stable and rated for your weight.

Understanding Crown Molding Types and Materials

Not all crown molding is created equal! The material you choose will affect how it’s cut, installed, and its overall look and feel. Here’s a quick rundown:

- Polyurethane/Foam: Lightweight, often pre-primed. Easy to cut and install, resistant to moisture. Great for DIYers due to its ease of use.

- Wood (Pine, Poplar, Oak, Maple): Offers a classic, high-quality look. Takes paint or stain beautifully. Can be heavier and prone to splitting if not handled carefully. Requires more precise cuts. Poplar is a good beginner-friendly wood choice due to its softness.

- MDF (Medium-Density Fiberboard): Affordable and paintable. Can be heavy, less moisture-resistant than polyurethane. Needs careful handling and finishing.

- PVC: Very durable, moisture-resistant, and lightweight. Can be more expensive.

For beginners, starting with a softer wood like pine or poplar, or a lightweight polyurethane molding, can make the process smoother.

The Crucial First Step: Planning and Measuring

Good planning prevents poor performance, as they say! Before you even think about cutting, measure your room carefully. Measure each wall section where the molding will go. It’s best to measure along the wall, at the height where the molding will sit, rather than trying to measure the angled length of the molding itself just yet.

Mark the starting and ending points for each piece of molding. Account for doorways, windows, and any other obstructions. Always measure twice, cut once – it’s a cliché for a reason!

Mastering the Miter Saw: Your Key to Perfect Cuts

This is where the magic happens, and where many beginners get a little nervous. Crown molding installation relies heavily on making accurate angled cuts, known as miter cuts.

Inside Corners: The Cozy Embrace

Inside corners are where two walls meet to form an internal angle. Typically, you’ll use a 45-degree miter cut for each piece of molding meeting in an inside corner. This creates a perfect 90-degree turn.

The Nailerguy Tip: The “Hats Off” Method

The easiest way to cut crown molding for inside corners on a standard miter saw is to lay the molding flat against the saw’s fence and miter table – the same way it will sit on the wall. You then set your saw to a 45-degree angle. For the left-hand wall, you’d make a cut with the molding’s back against the fence, angled away from the fence. For the right-hand wall, you’d make a cut with the molding’s back against the fence, angled towards the fence. It looks like you’re taking the hat off the molding!

A great resource for understanding these cuts is from Woodworkers Journal, which explains different saw setups for precise crown molding cuts.

Outside Corners: Reaching Outward

Outside corners are where walls meet externally, like on a bay window or the exterior of a room. Again, you’ll typically use 45-degree miter cuts. For outside corners, the molding pieces will meet at an angle pointing outwards.

The Nailerguy Tip: The Mirror Image

When cutting for an outside corner, the orientation of the molding on the saw is the same as for an inside corner (flat against the fence), but the direction of the cut is mirrored. If your first piece for an inside corner was cut with the blade moving left-to-right across the molding, the corresponding outside corner cut might be right-to-left, or vice-versa, depending on how you’re positioning. Think of the two pieces creating a “point” rather than a “valley” where they join.

| Corner Type | Common Angle | Cutting Method on Miter Saw | Resulting Joint |

|---|---|---|---|

| Inside | 45 degrees (each piece) | Lay molding flat against fence. | Forms a “valley” or internal corner. |

| Outside | 45 degrees (each piece) | Lay molding flat against fence. | Forms a “peak” or external corner. |

Trimming Around Obstacles: Doors and Windows

When you encounter a door or window frame, you’ll need to transition the crown molding. This often involves a spring angle cut (a miter cut that isn’t a perfect 45 degrees) to meet the frame at a specific angle, or sometimes it will simply butt up against the frame, depending on the design.

For experienced DIYers or those undertaking more complex designs, understanding the “spring angle” is key. This is the angle at which the molding sits between the wall and ceiling. Most crown molding has profiles designed to work with standard spring angles (often around 38-52 degrees). When you miter for corners, you’re setting two pieces with opposing spring angles to meet.

The Art of Nailing: Securing Your Molding

Now for the part that gives this guide its name: nailing! This is where your nail gun really shines.

Finding the Studs: The Foundation of a Strong Hold

Crown molding needs to be securely fastened. The best way to do this is to nail into the wall studs. Use your stud finder to locate studs along the wall where you’ll be installing the molding. Mark these stud locations lightly with your pencil. This ensures your molding won’t sag over time and will be held firmly in place.

Studs are typically spaced 16 or 24 inches apart on center. For a solid installation, aim to hit a stud with at least one nail in every few feet of molding, and definitely at the ends of each piece.

Nailing Strategy: Where and How to Shoot

When you’re ready to attach your crown molding:

- Start with a Test Piece: Before you commit to a long run, practice nailing on a scrap piece of molding applied to a wall. This allows you to check nail depth, spacing, and listen for any worrying sounds.

- Angle is Key: Drive your nails at a slight angle into the wall studs. This adds strength and helps the molding “key” into the wood behind it.

- Spacing Matters: Place nails about every 16-20 inches along the length of the molding, ensuring you hit studs whenever possible. Also, place a nail or two near the ends of the molding piece for better stability at the joints.

- Don’t Overdo It: You want a secure hold, not a nail-riddled piece of wood. Too many nails can also make filling and finishing more difficult.

- Nail into the Studs: This is the most important rule! If you miss a stud, the molding might not be as secure and could potentially sag later.

How to Nail Crown Molding Without Splitting Wood

This is a common concern, especially with harder woods or when nailing close to the edge. Here are my proven tips:

- Use the Right Nail Size: For most 3-5 inch crown molding, a 16-gauge finish nailer with 2-inch to 2.5-inch nails is ideal. Avoid using overly thick nails that are more likely to split.

- Pre-Drill for Stubborn Spots: If you’re working with a particularly hard wood or a tricky corner where the nails need to go in at an odd angle, it can be helpful to pre-drill a pilot hole slightly smaller than your nail. This is especially useful near end cuts.

- Nail Gun Depth Adjustment: Most nail guns have an adjustable depth setting. Experiment to find the sweet spot where the nail is driven flush or just slightly below the surface, but not so deep that it causes excessive damage or splits the wood.

- Soften the Wood (Optional): For very hard woods, applying a small amount of water or a wood lubricant to the spot where the nail will be driven can sometimes help. This is rarely necessary with standard hardwoods and modern nail guns.

- Nail Placement: Try to nail into the thicker parts of the molding profile where possible, away from the very thin edges.

- Use a Brad nailer for Intricate Areas: In some cases, a smaller 18-gauge brad nailer can be used for very delicate areas or to supplement a finish nailer, providing a gentler hold.

For more detailed information on using nail guns safely and effectively, check out the OSHA fact sheet on powder-actuated tools, which covers some related safety principles for fastening tools.

Mastering Interior Corners: The Coping Technique

While a perfect 45-degree miter works for many outside corners and some inside corners, the most professional and forgiving method for inside corners is often “coping.”

What is Coping?

Coping involves cutting one piece of molding to fit the profile of the other piece that’s already installed on the adjacent wall. It’s like creating a puzzle piece that perfectly matches the curves and contours.

How to Cope Crown Molding:

- Miter the First Piece: Cut the first piece of molding for the inside corner with a slight (e.g., 5-degree) miter cut, just as you would for a standard inside corner. Install this piece, nailing it securely.

- Measure the Second Piece: Place the second piece of molding on the adjacent wall. You want it to extend just past the corner.

- Mark the Profile: Mark the wall where the first piece of molding meets the wall. This line indicates where your coping cut needs to stop.

- Cut to the Profile: This is the trickiest part. You’ll need your coping saw or oscillating tool. With the molding piece positioned as it will be installed, carefully cut along the visible profile line. You want to create a backward-facing slope on the cut edge. The goal is to have the cut edge perfectly match the contour of the first piece.

- Test the Fit: Lightly fit the coped piece into the corner. You may need to trim or shave a bit more to get a snug fit.

- Nail in Place: Once you have a good fit, nail the coped piece into place, ensuring it’s tight against its mate.

Coping allows for slight imperfections in your wall angles and provides a much tighter, more seamless joint than even the most perfect miter. It takes practice, but it’s a skill that will elevate your finish carpentry.

Seamless Transitions: Filling and Finishing

Once all your crown molding is in place, it’s time for the finishing touches. This is where you transform raw installation into a polished, professional look.

Filling Nail Holes

Use a paintable wood filler or putty to fill all the nail holes. Oversize the hole slightly with the filler, then scrape it smooth with a putty knife. Let it dry completely according to the product instructions.

Caulking Gaps

This is arguably one of the most important steps for a professional finish. Run a bead of paintable caulk along every seam:

- Where the top edge of the molding meets the ceiling.

- Where the bottom edge of the molding meets the wall.

- At all inside and outside corner joints (even if they look good, caulk hides tiny imperfections and allows for slight expansion/contraction).

For a perfect caulk line, wet your finger or a damp cloth and run it gently along the bead of caulk to smooth it out. This creates a clean, continuous line that makes the molding look like it’s part of the wall.

Sanding and Priming

Once the wood filler and caulk are dry, lightly sand any rough spots or excess filler. If you used wood molding and plan to paint, apply a coat of primer. This seals the wood and provides an even surface for your topcoat.

Painting

Finally, paint your crown molding! You can use a brush for cutting in along the edges or a small roller for larger flat surfaces. Consider painting the molding the same color as your ceiling for a less intrusive look, or a contrasting color for a bolder statement. Always apply at least two coats for even coverage.

Troubleshooting Common Crown Molding Problems

Even with the best advice, you might run into a few hiccups. Here’s how to handle them:

Problem: Molding won’t sit flat against the wall or ceiling.

Solution: This usually means your miter cuts aren’t precise enough, or your wall/ceiling angle isn’t a perfect 90 degrees. If you’re not coping, try adjusting your miter saw angle slightly. If you are coping, refine your coping cut. Sometimes, a slightly heavier bead of caulk can help hide minor gaps, but significant gaps indicate a cutting issue.

Problem: Gaps at the corners.

Solution: If the gaps are small, a good bead of caulk will hide them. For larger gaps, you may need to recut the molding. For inside corners, focus on improving your coping technique. For