Have you ever wondered how machine shops cut through tough materials with ease? One of the key tools they rely on is a heavy duty bandsaw. This powerful machine can slice through metal, wood, and more, making it a vital part of any shop.

Imagine a busy workshop filled with the sounds of cutting and shaping. What makes the heavy duty bandsaw stand out? Its ability to handle large and hard pieces with precision. This means fewer mistakes and smoother edges, which every craftsman loves.

In this article, we will explore why the heavy duty bandsaw is a must-have for any serious machine shop. From its strong construction to its impressive capabilities, we’ll dive into all the reasons this machine is a favorite.

Could you picture a shop without one? It would be like a chef without a knife! Let’s uncover the secrets behind choosing the right heavy duty bandsaw for your needs.

Table of Contents

Choosing The Right Heavy Duty Bandsaw For Machine Shop Use

Heavy Duty Bandsaw for Machine Shop

A heavy duty bandsaw is essential for any machine shop. Do you often cut tough materials? This powerful tool can slice through metal and wood with ease. It offers precision and speed, making complex tasks simple. Operators value its safety features, reducing accidents during use. Did you know a good bandsaw can last for decades? Investing in a quality bandsaw means better efficiency and results in your projects. Upgrade your shop with this reliable equipment today!Understanding Heavy Duty Bandsaws

Definition and purpose of heavy duty bandsaws in machine shops. Key features that distinguish heavy duty bandsaws from standard models.Heavy duty bandsaws are like the superheroes of the machine shop. They cut through tough materials with ease, making them perfect for big projects. Unlike standard saws, they feature stronger motors and larger blades, which help tackle thicker items without breaking a sweat. Think of it this way: a heavy duty bandsaw can slice through metal like a hot knife through butter!

| Feature | Heavy Duty Bandsaw | Standard Bandsaw |

|---|---|---|

| Motor Power | High power | Lower power |

| Blade Size | Larger blades | Smaller blades |

| Material Capability | Thicker materials | Thinner materials |

So, whether you’re in a shop building a statue or crafting a metal masterpiece, a heavy duty bandsaw is your best friend for effective and precise cuts.

Benefits of Using Heavy Duty Bandsaws

Enhanced cutting capacity and precision for various materials. Increased productivity and efficiency in machine shop operations.Heavy duty bandsaws are like the superheroes of machine shops. They can cut through many materials with ease, from wood to metal, which means you can tackle various projects. This enhanced cutting capacity saves you time and increases precision — no more wonky cuts! With faster operations, you’ll see a boost in productivity. Remember, a happy shop makes for happy workers, or at least fewer coffee breaks when the job gets done quicker!

| Benefit | Description |

|---|---|

| Enhanced Cutting Capacity | Effortlessly cuts multiple materials. |

| Increased Productivity | Faster operations = more time for snacks! |

Top Features to Look for in a Heavy Duty Bandsaw

Blade size and type considerations. Motor power and speed options.Picking a heavy-duty bandsaw? Check out the blade size and type first. A bigger blade means you can cut thicker materials. Look for blades made from high-quality steel for sharpness and durability. Next up is motor power—more power means you can slice through tough stuff like a hot knife through butter. Speed options are crucial too. Fast speeds work great for thin materials. But with thick ones, slower speeds can help avoid mess-ups.

| Feature | Consideration |

|---|---|

| Blade Size | Bigger blades for thicker cuts |

| Blade Type | High-quality steel for durability |

| Motor Power | More power for tougher materials |

| Speed Options | Fast for thin, slow for thick |

Choose wisely, and you’ll be the bandsaw boss of the shop! Who knew power tools could be so… exhilarating?

Choosing the Right Heavy Duty Bandsaw for Your Shop

Assessing your specific machining needs and materials. Evaluating shop space and layout requirements.Finding the perfect bandsaw for your shop is like choosing the right pizza topping—everyone has their favorite, but you need to know your needs first! Start by figuring out what materials you’ll cut. Are you slicing thick metal or delicate wood? This helps narrow your options. Next, check your shop space. Is it a cozy closet or a spacious garage? Make sure your chosen saw fits without causing a traffic jam! A little planning goes a long way in avoiding shop chaos.

| Considerations | Questions to Ask |

|---|---|

| Machining Needs | What materials will I cut? |

| Shop Space | How much room do I have? |

Maintenance and Care for Heavy Duty Bandsaws

Routine maintenance tasks to ensure longevity. Troubleshooting common issues and repairs.To keep your heavy-duty bandsaw humming, routine maintenance is key. Regularly check the blades and ensure they’re sharp—dull blades can turn your smooth cuts into wobbly adventures. Lubricate moving parts, and clean sawdust to avoid a fire hazard. Having issues? Don’t panic! Most problems are easy to fix. Check the power supply and ensure nothing is clogged. Here’s a handy table for quick reference:

| Task | Frequency |

|---|---|

| Check Blades | Weekly |

| Lubricate Parts | Monthly |

| Clean Sawdust | After Each Use |

Taking care of these tasks helps your bandsaw last longer. Remember, “A happy saw is a cutting saw!”

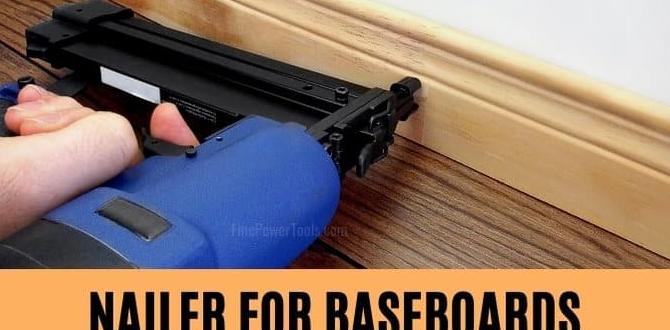

Safety Considerations When Operating Heavy Duty Bandsaws

Essential safety gear and practices for operators. Common hazards and how to mitigate risks during use.Operating a heavy-duty bandsaw requires serious safety measures. First, wear essential gear like goggles, gloves, and ear protection. These items shield you from flying debris and loud noise. Next, always keep your hands away from the blade. Think of it like a hungry monster just waiting to snap!

Common hazards include kickback and blade breakage. To avoid these, ensure that the blade is tight and well-maintained. Always double-check your work area for clutter and obstacles. Here’s a quick table for easy safety tips:

| Safety Gear | Hazards | Mitigation Strategies |

|---|---|---|

| Goggles | Kickback | Ensure proper blade tension |

| Gloves | Blade breakage | Regular maintenance |

| Ear protection | Debris | Keep area clean |

Stay alert and enjoy the process—it’s all about creating safely! Remember, a little caution goes a long way, like keeping cake away from a diet plan!

Cost Analysis: Investing in a Heavy Duty Bandsaw

Initial investment versus longterm benefits and savings. Financing options and budget considerations for machine shops.Getting a heavy-duty bandsaw can feel like a big leap for your machine shop. Yes, the initial investment can be a bit scary. But think of it this way: it’s like buying a unicorn that can slice through metal!

In the long run, these saws save time and money, making every cut count. Consider financing options. Many shops find payment plans take the pressure off, while budgeting smartly can free up cash for snacks—and maybe some new tools too!

| Cost Analysis | Initial Expense | Long-term Savings |

|---|---|---|

| Heavy-Duty Bandsaw | High ($3,000-$10,000) | Low maintenance costs, efficient cutting leads to reduced waste |

| Financing Options | Varies by lender | Possibility of lower monthly payments |

Conclusion

In summary, a heavy-duty bandsaw is essential for any machine shop. It cuts tough materials easily and operates efficiently. With its power, you can complete projects faster and more accurately. If you’re working in a shop, consider investing in one. You can find more information online to help you choose the right bandsaw for your needs.FAQs

What Are The Key Features To Look For In A Heavy-Duty Bandsaw For A Machine Shop?When you look for a heavy-duty bandsaw for a machine shop, check how strong it is. You want a sturdy frame that won’t shake. Look for a powerful motor so it can cut tough materials. Make sure it has easy controls so you can use it safely. Finally, a good blade size helps you cut big pieces smoothly.

How Does The Cutting Capacity Of A Heavy-Duty Bandsaw Affect Its Performance In A Machine Shop Environment?The cutting capacity of a heavy-duty bandsaw tells you how thick and wide materials it can cut. A bigger cutting capacity means you can work on larger pieces. This helps you finish jobs faster and make better products. In a machine shop, this means we can take on more projects and keep customers happy.

What Safety Precautions Should Be Observed While Operating A Heavy-Duty Bandsaw In A Machine Shop?When using a heavy-duty bandsaw, always wear safety goggles to protect your eyes. Keep your hands away from the blade while cutting. Make sure the machine is turned off before changing blades or cleaning. Use the proper push sticks to guide the material. Always follow the instructions for safe use.

How Do Different Blade Types Influence The Cutting Efficiency And Quality Of A Heavy-Duty Bandsaw?Different blade types can change how well a heavy-duty bandsaw cuts. For example, some blades are thin and can cut faster but might not be as smooth. Other blades are thicker and cut slowly, but they make cleaner edges. Choosing the right blade helps you cut better and achieve good results in your projects.

What Maintenance Practices Are Essential For Ensuring The Longevity And Reliability Of A Heavy-Duty Bandsaw In A Machine Shop?To keep a heavy-duty bandsaw in good shape, we need to do a few simple things. First, always clean the saw after using it to remove dust and sawdust. Second, we should check the blade often for wear and replace it if it’s dull. Third, we need to oil the moving parts to keep them working smoothly. Lastly, we should tighten any loose screws and check for any damage regularly.