Quick Summary

Don’t let an air hose leak slow down your woodworking projects! This guide teaches you how to easily find and fix leaks in your nailer’s air hose, saving you time and frustration. We’ll cover common culprits, simple repair steps, and tips to prevent future issues, ensuring your nailer runs smoothly.

Hey there, fellow DIYers and aspiring woodworkers! Jack Shaffer here from Nailerguy. Ever been in the middle of a project, ready to drive a nail, only to hear that disheartening hiss of escaping air? It’s one of those little frustrations that can really throw a wrench in your workflow. A leaky air hose is a common problem, but thankfully, it’s usually a pretty simple one to fix. You don’t need to be a master mechanic to get your air supply back in tip-top shape.

The good news is that most air hose leaks are caused by straightforward issues, like loose connections or minor damage. With a few basic tools and a little bit of patience, you can pinpoint the leak, patch it up, and get back to building. We’ll walk through the entire process, from identifying the source of the hiss to making a durable repair. Ready to silence that leak and power up your nailer?

Table of Contents

Why Does My Nailer Air Hose Leak? Common Culprits

It’s frustrating when your air compressor sounds like a leaky balloon, but understanding why it happens is the first step to fixing it. Air hoses are subjected to a lot of abuse, from being dragged across job sites to being coiled up and stored. These everyday actions can lead to a few common problems that cause air to escape. Pinpointing the exact spot of the leak is key to a successful repair.

Let’s break down the most frequent reasons for an air hose leak:

- Loose Fittings: This is by far the most common cause. The fittings that connect the hose to the compressor and the nailer can simply work themselves loose over time with vibration and movement.

- Worn or Damaged Couplers: The quick-connect couplers on either end of the hose can get bent, cracked, or have their internal seals damaged. This prevents them from creating a tight seal.

- Hose Kinks and Cracks: If the hose has been severely kinked, it can create weak spots or even small punctures. Age and exposure to sunlight can also make the rubber brittle, leading to cracks.

- Punctures and Cuts: Accidental drops of tools, stepping on the hose, or the hose rubbing against sharp objects can cause direct punctures or cuts.

- Internal Hose Damage: Sometimes, the rubber lining inside the hose can degrade, especially if oil from the compressor is getting into the air line. This can cause leaks that are harder to find.

How to Find the Source of Your Air Hose Leak

Before you can fix an air hose leak, you need to find it! This might sound obvious, but sometimes the hiss can be deceiving, making you think the problem is in one spot when it’s actually somewhere else. We’ll use a simple, effective method that anyone can do. Safety first, so make sure your compressor is turned off and unplugged before you start inspecting closely.

The Soap and Water Test

This is the go-to method for finding tiny leaks that you can’t see or hear easily. It’s a tried-and-true technique for locating those sneaky air escape routes.

- Prepare the Mixture: In a spray bottle or a small bucket, mix a generous amount of dish soap with water. You want a solution that’s noticeably soapy – thicker is better for helping bubbles form.

- Pressurize the System: Connect your air hose to the compressor. Turn the compressor on and let it build up a good amount of pressure. Don’t over-pressurize it, just get it to a working level. Your nailer doesn’t need to be attached for this test, but the hose needs to be pressurized.

- Spray Down the Hose: Methodically spray or wipe the soapy water all along the length of the air hose. Pay extra attention to the areas around the fittings, couplers, and any spots that look kinked or damaged.

- Look for Bubbles: Watch carefully. As the soapy water comes into contact with a leak, the escaping air will create bubbles. The larger and more persistent the bubbles, the bigger the leak.

- Inspect Fittings and Couplers: Don’t forget to spray the soapy water directly onto the fittings and inside the couplers themselves. Leaks here are very common.

- Mark and Confirm: Once you find a bubbling spot, mark it with a marker or piece of tape. If you’re unsure, try spraying more soapy water on that specific spot to confirm it’s indeed the leak.

This method is great because it visibly shows you where the air is escaping, removing all the guesswork. Once you’ve identified one or more leak points, you’re ready to move on to the repair.

Essential Tools and Materials for Air Hose Repair

You don’t need a professional workshop to fix an air hose leak. Most of the tools you’ll need are probably already in your toolbox, or they are inexpensive to pick up. Having the right materials on hand will make the repair process smooth and ensure a lasting fix.

Tools You’ll Likely Need:

- Adjustable wrench or a pipe wrench (for stubborn fittings)

- Pliers (needle-nose and regular)

- Utility knife or hose cutter (for trimming damaged hose sections)

- Screwdriver (Phillips or flathead, depending on your hose clamp type)

- Masking tape or permanent marker (for marking leaks)

- Gloves (for grip and protection)

- Safety glasses (always wear them when working with tools and pressurized air!)

Repair Materials:

The materials you’ll need depend on the type of leak you’ve found. Here are some common options:

- Hose Repair Kit: These kits are specifically designed for rubber air hoses and often include new fittings, ferrules (sleeve-like clamps), and sometimes even new couplers. They are a great option for a robust repair.

- Replacement Couplers: If the leak is specifically in the coupler, you can buy a direct replacement. Make sure it matches the size and type (e.g., industrial, M-style) of your existing coupler.

- Hose Clamps: For smaller punctures or splits where you can’t replace a section of hose, heavy-duty hose clamps can work.

- Duct Tape or Specialized Hose Tape: For very minor, temporary fixes or to reinforce a repair, strong tape can be a lifesaver. However, this is generally not recommended for long-term, high-pressure solutions.

- Self-Fusing Silicone Tape: This tape stretches and fuses to itself to create a watertight and airtight seal. It’s a more durable tape solution than standard duct tape for some repairs.

We’ll discuss different repair methods based on the type of leak, so you can choose the best approach.

Step-by-Step Guide: Fixing Your Nailer Air Hose Leak

Now that you know where the leak is and have your tools ready, let’s get down to fixing it. We’ll break this down into different scenarios, as the fix will vary slightly depending on the problem.

Scenario 1: The Loose Fitting

This is the easiest fix! If your soap test revealed that a fitting just needs tightening, you’re in luck.

- Turn Off Air Supply: Ensure the compressor is off and unplugged. Release any remaining pressure in the hose by disconnecting it from the compressor.

- Locate the Loose Fitting: Identify the fitting that is bubbling – this is typically where the metal end of your hose screws into a coupler or onto the compressor’s quick-connect stem.

- Tighten the Fitting: Use an adjustable wrench or pipe wrench to gently tighten the fitting. Turn it clockwise. Be firm but don’t overtighten; you don’t want to strip the threads or crack the fitting.

- Test for Leaks: Reconnect the hose, pressurize the system, and perform the soap test again on the tightened fitting.

- Confirm the Fix: If the bubbling stops, congratulations! You’ve fixed the leak. If it continues, the fitting itself might be damaged, or the threads might be stripped, and you may need to consider replacing the fitting.

Scenario 2: Damaged Coupler or Connector

The quick-connect couplers are workhorses, but they can take a beating. If the problem is with the coupler itself, it’s often best to replace it.

- Safety First: Turn off the compressor and release all air pressure from the hose.

- Remove the Old Coupler:

- For screw-on couplers: Use your adjustable wrench to unscrew the old coupler from the hose end.

- For crimped-on couplers: These are usually secured with a metal ferrule. You might need a specialized ferrule crimper/remover tool, or you can sometimes carefully cut the ferrule off with a hacksaw or rotary tool, being careful not to cut into the hose itself.

- Prepare the Hose End: If you had to cut off a ferrule, clean up the end of the hose. If the hose end itself is frayed or damaged, use a utility knife or hose cutter to trim it cleanly. Make sure you have enough hose length to attach a new coupler securely.

- Install the New Coupler:

- For screw-on couplers: Wrap the threads of the new coupler with plumber’s tape (PTFE tape) for a better seal. Screw the new coupler onto the hose end, tightening it with a wrench.

- For crimped-on couplers: Slide a new ferrule onto the hose. Insert the hose into the new coupler, ensuring it’s seated properly. Use a ferrule crimping tool to secure the ferrule tightly around the hose and coupler. This creates a very strong, leak-proof connection.

- Pressurize and Test: Reconnect the hose, turn on the compressor, and conduct the soap test on the new coupler and fitting.

Replacing couplers is a common repair and makes your hose feel almost new again. You can usually find replacement coupler kits at your local hardware store or from online tool suppliers. Check out resources like OSHA’s safety standards for pneumatic tools to understand the importance of proper fittings and connections for safe operation.

Scenario 3: Hose Puncture, Cut, or Crack

Dealing with damage to the hose body itself requires a slightly different approach, depending on the severity.

Minor Punctures or Small Cracks: Reinforcement Method

If you found a very small hole or a hairline crack and you need a quick fix, you can try reinforcing it.

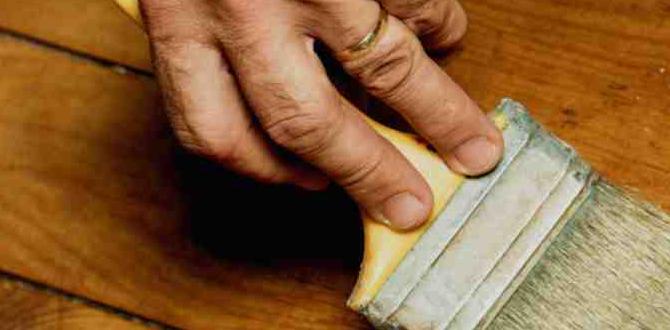

- Clean the Area: Ensure the area around the leak is clean and dry.

- Apply Sealant: You have a couple of good options here:

- Self-Fusing Silicone Tape: Wrap this tape tightly around the damaged area, stretching it as you go. It will fuse to itself, creating a robust, waterproof, and airtight seal. Apply several layers.

- Specialized Hose Repair Tape: Some heavy-duty tapes are designed specifically for rubber hoses. Follow the manufacturer’s instructions.

- Consider Hose Clamps: For a more mechanical fix on a small puncture or split, you can clean the area, then wrap it with a patch of rubber (if you have any scrap) and secure it tightly with a heavy-duty hose clamp or two.

- Test Carefully: After applying your chosen method, let it cure if required, then pressurize the hose and perform the soap test to ensure the leak is sealed.

Important Note: While these methods can work for minor leaks, they are often temporary fixes. For critical applications or larger damage, replacing the hose is the safest and most reliable option.

Larger Cuts, Splits, or Severe Kink Damage: Hose Replacement

If the hose has a significant cut, a long split, or damage from severe kinking that has compromised its integrity, the safest and most effective solution is to replace the entire hose.

- Purchase a New Hose: Get a quality air hose of the same length and diameter as your old one. Consider braided rubber hoses or reinforced PVC hoses for durability. Look for hoses rated for the pressure your compressor puts out.

- Attach New Fittings/Couplers: Your new hose might come with fittings, or you might need to transfer your existing ones. If you’re transferring them, follow the steps in “Scenario 2: Damaged Coupler or Connector” for removing and installing fittings and couplers. If the new hose came with new fittings, follow the manufacturer’s instructions for attachment, which often involves clamping or screwing them on.

- Ensure Tight Seals: Double-check that all fittings and couplers are installed correctly and securely.

- Test Thoroughly: Connect the new hose, pressurize, and perform the soap test along the entire length, paying attention to the new connections.

Replacing the hose entirely might seem like more work, but it guarantees a safe and reliable air supply for your tools. A damaged hose can lead to unexpected failures, which can be dangerous.

Table: Common Air Hose Problems and Their Fixes

Here’s a quick reference to help you diagnose and fix your air hose issues:

| Problem Type | Likely Cause | Recommended Fix | Difficulty Level | Longevity |

|---|---|---|---|---|

| Loose Fitting / Connection | Vibration, improper initial tightening | Re-tighten fitting; if still leaking, consider replacing fitting or coupler. | Easy | High (if re-tightened properly) |

| Damaged Coupler (Cracked, Bent) | Dropping, impact, age | Replace the entire coupler. | Medium | High |

| Minor Puncture / Pin Hole | Sharp object, snag | Reinforce with self-fusing silicone tape or a specialized hose repair patch. | Medium | Medium (often temporary) |

| Small Split / Hairline Crack in Hose | Kinking, age, stress | Reinforce with self-fusing silicone tape or a hose clamp with rubber padding. | Medium | Medium (often temporary) |

| Large Cut / Deep Split / Hose Degredation | Significant damage, age, abrasion | Replace the entire air hose. | Medium to Hard (depending on fitting type) | Very High (new hose) |

| Kinked Hose Damage | Improper storage, excessive bending | If the kink is minor and no visible damage, try to unkink. If damaged, replace hose. | Easy to Hard | Variable to Very High (new hose) |

Preventing Future Air Hose Leaks

An ounce of prevention is worth a pound of cure, as they say! Taking a few simple precautions can significantly extend the life of your air hose and prevent those frustrating leaks from happening in the first place.

- Proper Coiling: When you’re done using your air hose, coil it loosely. Avoid tight bends, which can stress the rubber and lead to premature cracking, especially in cold weather. Never coil it around sharp corners.

- Avoid Dragging: Try to lift and carry the hose rather than dragging it across rough surfaces, concrete, or gravel. Dragging can cause abrasion and small punctures.

- Store Safely: Store your hose away from direct sunlight, extreme heat, or chemicals, as these can degrade the rubber over time. A hose reel or a designated hook is a great way to keep it organized and protected.

- Regular Inspection: Make it a habit to inspect your hose before and after each use. Look for any signs of wear, cracks, kinks, or damage to the fittings and couplers. A quick visual check can save you a lot of trouble.

- Use the Right Air Pressure: Make sure your compressor isn’t over-pressurizing the hose or your tool. Use a regulator to set the appropriate pressure for your nailer. Excessive pressure puts undue stress on the hose and fittings.

- Drain Your Compressor Tank: Regularly drain the moisture from your air compressor tank. Water can build up and, over time, degrade the inside of rubber hoses, making them brittle and prone to leaks. For more on compressor maintenance, check out guides from reputable