Build your own sturdy and stylish wooden outdoor dining set without breaking the bank! This guide offers budget-friendly plans, essential tool tips, and step-by-step instructions for a rewarding DIY project.

Dreaming of al fresco dinners but wincing at the price tags of outdoor furniture? You’re not alone! Many of us love the idea of eating under the open sky, but finding an affordable yet durable dining set can feel like searching for a unicorn. That’s where a smart DIY project comes in. We’re going to build a fantastic wooden outdoor dining set that looks great, lasts for years, and best of all, keeps your wallet happy. Don’t worry if you’re new to woodworking; I’ll break it down into simple steps, just like I do with picking the right nailer. Get ready to transform your backyard!

Table of Contents

Why Build Your Own Wooden Outdoor Dining Set?

Building your own wooden outdoor dining set is more than just a way to save money. It’s a chance to craft something unique, tailored to your space and style. Plus, the satisfaction of creating something tangible with your own hands is incredibly rewarding. When you build it yourself, you control the quality of materials, ensuring it can withstand the elements better than many store-bought options. We’ll focus on maximizing durability and minimizing cost, so you get a true masterpiece.

Choosing Your Wood: Budget-Friendly & Durable Options

The type of wood you choose makes a big difference in both cost and longevity. For an outdoor set, you need something that can handle sun, rain, and maybe even a bit of snow. We’ll look at options that offer a good balance of affordability and weather resistance.

Here are some top picks for a budget-friendly outdoor dining set:

- Pine (Treated): This is often the most budget-friendly option. When pressure-treated, pine gains significant resistance to rot, decay, and insects. It’s widely available and easy to work with. Just be sure to check for a treatment rating suitable for ground contact if your furniture will be in constant contact with soil.

- Cedar: Natural oils in cedar make it highly resistant to decay and insects. It’s lighter than some hardwoods and has a beautiful, natural aroma and color. While it can be pricier than treated pine, its inherent durability means less maintenance over time.

- Fir (Douglas Fir): Similar to pine, Douglas fir is strong and relatively affordable. It’s quite resistant to decay, especially if sealed properly. It’s a great choice for a sturdy build that can also be painted or stained to match your aesthetic.

- Cypress: Known for its exceptional durability and resistance to insects and rot, cypress is a fantastic outdoor wood. It can be a bit more expensive than pine or fir, but its natural longevity makes it a worthwhile investment for those wanting a set that lasts decades.

For this project, we’ll primarily focus on using treated pine or fir because they offer the best combination of cost-effectiveness and durability for beginners. You can find detailed information on wood treatments and safety at the Forest Products Laboratory Wood Use Handbook (.pdf download from USDA Forest Service).

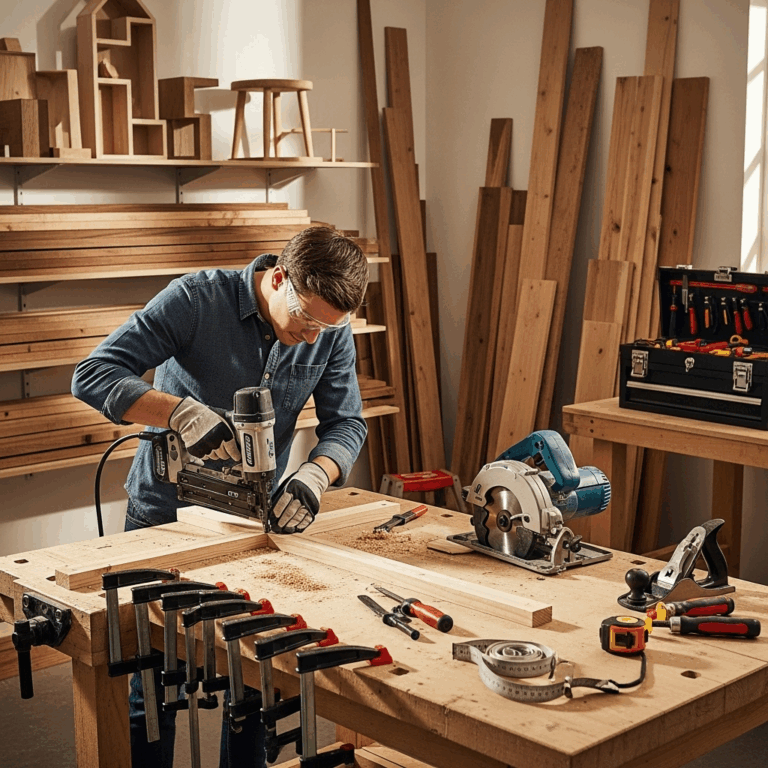

Essential Tools for Your DIY Dining Set Project

You don’t need a professional workshop to build a great dining set. Here are the essential tools that will make your job easier and safer. If you’re just starting out, consider borrowing, renting, or opting for more basic models of these tools.

Cutting Tools

- Circular Saw: This is your go-to for making straight cuts on lumber. It’s versatile and essential for cutting pieces to size. Look for one with a decent power rating for easier work.

- Miter Saw (Optional but Highly Recommended): A miter saw makes precise angled cuts, which are super helpful for cutting legs and supports to the correct angles. It significantly speeds up the process and ensures accuracy.

- Jigsaw: Useful for curved cuts or trimming awkward spots, though less critical for a basic dining set.

Measuring & Marking Tools

- Tape Measure: A standard 16-foot or 25-foot tape measure is a must.

- Pencil: For marking your cut lines.

- Carpenter’s Square: Essential for marking straight 90-degree lines and checking squareness.

- Speed Square: A handy triangular tool that helps mark 90 and 45-degree angles quickly and aids in guiding your circular saw for straight cuts.

Assembly Tools

- Drill/Driver: A cordless drill is indispensable for drilling pilot holes and driving screws. Look for a model with good battery life and torque. I’m a big fan of brushless motors for added power and efficiency!

- Driver Bits: Ensure you have the correct screwdriver bits (Phillips, square drive, etc.) to match your screws.

- Countersink Bit: This allows screw heads to sit flush or below the wood surface, giving a cleaner look and preventing snags.

- Clamps: Various sizes of clamps (bar clamps, pipe clamps, C-clamps) are invaluable for holding pieces together while you drill and screw. They ensure tight joints.

Safety Gear (Non-negotiable!)

- Safety Glasses: Always wear safety glasses when cutting, drilling, or sanding. Your eyes are precious!

- Hearing Protection: Power tools are loud. Use earplugs or earmuffs to protect your hearing, especially during extended use.

- Work Gloves: Protect your hands from splinters and rough wood.

- Dust Mask: Especially important when sanding. Wood dust can be harmful to inhale.

A nail gun, like a framing nailer or even a brad nailer, can certainly speed things up and provide strong joints, but for a beginner-friendly budget build, screws are perfectly adequate and often more forgiving.

Design Ideas: Simple & Sturdy

For a budget-friendly, beginner-friendly project, we’ll focus on a classic and robust design. This typically involves a rectangular table with sturdy legs and simple benches that tuck neatly underneath. The key is to keep the joinery straightforward.

Table Design Considerations

- Size: A common size for a 6-seater table is around 6 feet long, 3 feet wide, and 30 inches high. Adjust this to fit your patio or deck and the number of people you usually entertain.

- Legs: Simple mortise and tenon joints or even just sturdy aprons with strong corner braces are effective. For the absolute simplest build, legs attached directly to the underside of the tabletop supports are an option.

- Top: A series of planks for the tabletop is easy to assemble and looks great. You can create a small gap between planks for drainage if desired.

Bench Design Considerations

- Height: Benches should be about 18 inches high to match standard dining table height.

- Length: Aim for benches that are slightly shorter than the table’s length, allowing for easy access.

- Construction: Similar construction to the table legs – sturdy, simple, and functional.

We’ll base our steps on a table and two benches. You can find plenty of free plans online from reputable sources like DIY sites or woodworking magazines that offer detailed cuts and measurements based on similar principles.

Step-by-Step Guide: Building Your Dining Set

Let’s get building! This guide will walk you through creating a classic, sturdy wooden dining set. Remember to always double-check your measurements before cutting!

Phase 1: Preparing Your Materials & Cutting Pieces

- Gather Your Lumber: Based on your chosen design (we’ll assume a 6-foot table and two 4-foot benches), purchase your lumber. For a 6-foot table, you might need boards like 2x6s for the tabletop, 4x4s for legs, and 2x4s for the frame and bench construction. Always buy a little extra for mistakes.

- Cut Tabletop Planks: Cut your 2×6 boards (or similar) to the desired table length (e.g., 72 inches). You’ll need enough to cover your desired width. Leave a small gap (1/4 inch) between planks for water drainage.

- Cut Table Frame (Apron): Cut 2×4 boards for the long aprons (e.g., 72 inches minus the width of two leg pieces) and short aprons (e.g., 36 inches minus the width of two leg pieces). These will attach the legs and support the tabletop.

- Cut Table Legs: Cut your 4×4 posts to your desired table height (e.g., 29 inches, accounting for tabletop thickness). Ensure all four legs are exactly the same length.

- Cut Bench Components:

- Bench Seat Planks: Cut 2x6s to the desired bench length (e.g., 48 inches).

- Bench Frame (Aprons): Cut 2x4s for the long and short aprons.

- Bench Legs: Cut 2x4s or 4x4s for the bench legs (e.g., 17 inches, again accounting for seat plank thickness). Make sure they are all the same length.

- Sand Edges: Lightly sand all cut edges to remove splinters and sharp corners. This makes handling the pieces much safer.

Phase 2: Assembling the Table

This is where your drill and screws come into play. Drilling pilot holes is crucial, especially with treated lumber, to prevent splitting.

- Assemble Table Legs and Aprons: Attach the short aprons to the ends of the long aprons, forming a rectangular frame. Pre-drill holes and use 3-inch exterior wood screws. Then, attach the legs to the inside corners of this apron frame. Use at least two screws per side of the leg, screwing from the apron into the leg. Ensure legs are square to the frame.

- Attach Tabletop Supports (Optional but Recommended): Cut additional 2×4 pieces to fit inside the apron frame, running perpendicular to the aprons. These will provide extra support for the tabletop planks. Screw them into the aprons.

- Attach Tabletop Planks: Position your cut 2×6 tabletop planks onto the apron frame (and supports if used). Ensure they are evenly spaced with small gaps for drainage. Secure each plank to the frame and any internal supports using 2.5-inch exterior wood screws. Drive screws through the planks into the supporting lumber below.

Phase 3: Assembling the Benches

The benches follow a similar construction logic to the table.

- Assemble Bench Legs and Aprons: Just like the table, create a rectangular frame with your 2×4 aprons. Then, attach the bench legs to the inside corners using 3-inch exterior wood screws.

- Attach Bench Seat Planks: Position the bench seat planks onto the assembled leg frame. Space them evenly and secure them using 2.5-inch exterior wood screws, driving them into the aprons and any internal supports.

- Repeat for Second Bench: Follow the same steps to build your second bench.

Phase 4: Finishing Touches

This is where you protect your creation and add your personal touch.

- Final Sanding: Once fully assembled, give your entire dining set a thorough sanding. Start with a medium-grit sandpaper (around 80-120 grit) to smooth out any rough spots, then follow up with a finer grit (180-220 grit) for a nice, smooth finish. Pay extra attention to the tabletop and bench seats.

- Apply a Finish: This is critical for protecting your wood from the elements.

- Sealant/Stain: For treated pine or fir, a good quality exterior wood sealant or stain will add UV protection and water resistance. Apply multiple coats according to the product instructions.

- Paint: If you prefer a pop of color, use a high-quality exterior paint designed for wood.

Allow the finish to cure completely before use, which can take several days depending on the product and weather conditions. You can find excellent guides on finishing techniques at resources like This Old House.

Budget Breakdown: A Real Look at Costs

Let’s talk numbers. The beauty of this DIY project is its affordability. Prices can vary significantly based on your location, lumber sales, and whether you already own some tools. This is an estimate for a functional, good-looking set.

| Item | Estimated Cost Range (USD) | Notes |

|---|---|---|

| Lumber (Treated Pine/Fir) | $150 – $300 | Depending on size and current market prices. Buy longer boards and cut to size. |

| Exterior Wood Screws | $20 – $40 | Good quality, corrosion-resistant screws are a must for outdoor use. |

| Exterior Wood Sealant/Stain/Paint | $30 – $70 | Covers all pieces generously. |

| Sandpaper & Other Supplies | $10 – $20 | Includes glue (optional), finishing rags, etc. |

| Total Estimated Cost: | $210 – $430 | |

Compare this to commercial sets that can easily run $800 to $2000+, and you can see the incredible value. If you own some basic tools, your upfront cost will be even lower.

Maintenance Tips for Longevity

To keep your DIY masterpiece looking great season after season, a little maintenance goes a long way.

- Annual Cleaning: Wash your set with mild soap and water to remove dirt and debris. A soft brush can help.

- Inspect for Damage: Check for any loose screws, splintering wood, or signs of rot. Address these issues promptly.

- Reapply Finish: Depending on your climate and the product used, you may need to reapply sealant or stain every 1-3 years. This is your primary defense against weathering.

- Storage (Optional): If you live in an area with harsh winters, consider covering your furniture or storing it in a shed or garage during the off-season. This significantly extends its life.

Proper maintenance ensures your budget masterpiece remains a beautiful and functional part of your outdoor space for many years.

Frequently Asked Questions (FAQ)

Q1: Is treated lumber safe for outdoor furniture?

Yes, modern pressure-treated lumber for residential use is safe when handled properly. It’s treated to resist rot and insects. Always wear gloves when handling it and avoid burning the scraps. Ensure you let it dry for a few weeks after purchase before applying a finish.

Q2: Can I build this set without a miter saw?

Absolutely! While a miter saw makes angled cuts easier, you can achieve straight cuts with a circular saw and a guide (like a speed square or a straight edge clamped to your wood). For legs, you can often use simple 90-degree cuts, which are very beginner-friendly.

Q3: What’s the easiest way to ensure my table is square?

Assemble the apron frame first. Measure the diagonals of the rectangle you’ve formed. If the measurements are equal, your frame is square. Adjust it gently until the diagonals match before securing it permanently or attaching legs. Your carpenter’s square or speed square is also essential for checking 90-degree angles as you go.

Q4: How do I prevent screws from splitting the wood?

Always drill pilot holes that are slightly smaller than the diameter of your screw threads. This creates a channel for the screw to pass through without forcing the wood fibers apart. A countersink bit used after drilling the pilot hole will allow the screw head to sit flush.

Q5: What if I don’t want gaps between my tabletop planks?

You can omit the gaps and butt the planks tightly together for a solid surface. However, be aware that without gaps, expanding and contracting wood due to moisture changes can cause warping or cracking over time. If you have perfect seasoning and a very stable climate, it can work. Alternatively, you can use tongue-and-groove or biscuit joinery for a more seamless