Have you ever seen a shiny piece of aluminum and wondered how it’s made? Cutting aluminum on a bandsaw is a magical process that transforms raw metal into useful shapes. Imagine being able to create anything from custom brackets to unique art pieces!

Many people think that cutting metal is hard work. However, with the right tools, like a bandsaw, it can be very simple. Bandsaws are great for this job because they cut smoothly and accurately. Have you ever tried to cut a soft drink can? It’s not that different!

In this article, you will learn how to safely cut aluminum on a bandsaw. You’ll discover tips and tricks that even beginners can follow. It’s exciting to think about what you can create! Are you ready to dive in and explore the world of aluminum cutting?

Table of Contents

Cutting Aluminum On Bandsaw: Tips And Techniques For Success

Cutting aluminum on a bandsaw offers precision and ease. Did you know that the right blade can make all the difference? A tooth pitch that matches your aluminum’s thickness prevents binding. Adjusting the speed also helps—it should be slower than cutting steel. A neat trick is to use wax to lubricate the blade, ensuring a smooth cut. Always wear safety gear, as flying chips can be sharp. Ready to slice through aluminum like a pro?

Understanding Bandsaw Basics

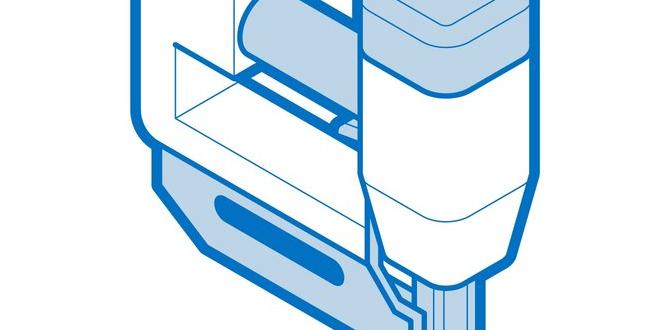

Explanation of bandsaw components and functionality. Types of bandsaws suitable for cutting aluminum.

A bandsaw has several key parts that work together. The blade cuts through materials like aluminum. The wheels spin the blade, keeping it moving. The table supports the aluminum as you cut. There are different kinds of bandsaws, each good for cutting aluminum. Some common types include:

- Vertical bandsaw: Perfect for precise cuts.

- Horizontal bandsaw: Great for larger pieces.

- Bench-top bandsaw: Compact and easy to move.

Understanding these parts helps you use a bandsaw safely and efficiently.

What are the main components of a bandsaw?

The main components include the blade, wheels, table, and motor.

Which types of bandsaws are best for cutting aluminum?

Vertical, horizontal, and bench-top bandsaws are ideal for aluminum.

Choosing the Right Blade for Aluminum Cutting

Material types and tooth geometry specifics. Recommended blade widths and TPI for different aluminum thicknesses.

Picking the right blade for cutting aluminum can feel like searching for a needle in a haystack — if that needle was made of metal and needed to slice through more metal! First, consider the material type. Aluminum is a soft metal, so you need teeth that can cut without bogging down. Look for blades with a higher tooth count, ideally around 10-14 teeth per inch (TPI) for thinner aluminum. For thicker pieces, a blade with 4-6 TPI works better.

The blade’s width matters too. A narrower blade can make tighter curves, while a wider blade is great for straight cuts. Don’t forget: a blade that’s too rough will leave your aluminum with a fuzzy haircut! Below is a simple guide:

| Aluminum Thickness | Recommended Blade Width | TPI |

|---|---|---|

| Up to 1/8″ (3mm) | 1/4″ (6mm) | 10-14 |

| 1/8″ to 1/4″ (3mm to 6mm) | 1/2″ (12mm) | 6-10 |

| 1/4″ (6mm) and thicker | 3/4″ (18mm) | 4-6 |

Choose wisely, and your cutting will be smooth sailing — or should I say, smooth slicing?

Preparing Aluminum for Bandsaw Cutting

Importance of cleaning and securing the workpiece. Best practices for measuring and marking cut lines accurately.

Cleaning and securing your aluminum piece helps avoid chaos while you cut. Dust and grime can make the job messier than a spaghetti dinner! Make sure everything is clamped down tight so it doesn’t skitter away like a startled squirrel.

Next, measuring and marking your cut lines accurately is crucial. Use a ruler and a pencil to draw lines with precision. A tiny mistake can lead to big trouble! Remember, “Measure twice, cut once,” or you might find your aluminum piece wishing it had stayed in the fridge!

| Best Practices | Tips |

|---|---|

| Clean Workpiece | Remove dust and grease for a smooth cut. |

| Secure Firmly | Clamp your piece to prevent movement. |

| Measure Carefully | Use a ruler for straight and precise lines. |

Setting Up Your Bandsaw for Optimal Performance

Adjustments to speed settings for aluminum cutting. Tips for maintaining blade tension and tracking.

To get the most out of your bandsaw, start with the right speed setting. For cutting aluminum, a medium speed often works best. This prevents overheating and keeps cuts smooth. Also, keeping the blade tension right is important. If it’s too loose, you may get wobbly cuts. If it’s too tight, the blade could break. Remember to check the blade tracking too; it should run straight along the wheel.

How do you adjust the bandsaw speed?

Adjust bandsaw speed by setting it to a medium range. This works well for aluminum cuts and helps avoid heat buildup.

Quick Tips for Maintenance

- Check blade tension regularly.

- Ensure proper blade tracking.

- Lubricate moving parts often.

Proper setup can make cutting aluminum easier and safer!

Cutting Techniques for Aluminum on a Bandsaw

Recommended cutting speeds and feed rates. Techniques to prevent blade binding and ensure smooth cuts.

To cut aluminum smoothly on a bandsaw, use the right speeds and feed rates. Generally, a speed of 200-300 SFM works well. Keep your feed rate steady to avoid blade binding. Also, here are some tips:

- Use a sharp blade designed for metal cutting.

- Keep the aluminum clean and free of grease.

- Apply cutting fluid for better results.

By following these techniques, you ensure smooth cuts and prevent issues as you cut.

What cutting speeds and feed rates are best?

Using a speed of 200-300 SFM and a steady feed rate helps in cutting aluminum effectively.

Safety Measures When Cutting Aluminum

Essential personal protective equipment (PPE). Safety protocols to follow during the cutting process.

Before you start cutting aluminum, safety is key. Always wear the right personal protective equipment (PPE). This includes:

- Safety goggles to protect your eyes from flying metal shards.

- Hearing protection to keep your ears safe from loud noises.

- Gloves to shield your hands from sharp edges.

- Steel-toed boots to protect your feet from heavy pieces.

Follow these safety protocols as you cut:

- Make sure the bandsaw is properly set up.

- Keep your hands away from the blade.

- Stay focused and avoid distractions.

- Clean up any spills or scraps right away.

Staying safe means you can enjoy your project without worries!

What precautions should I take when cutting aluminum?

The best precautions include wearing safety goggles, using hearing protection, and maintaining focus on cutting tasks.

Post-Cutting Process and Finishing Techniques

Removing burrs and smoothing edges after cutting. Options for further treatment or coating of the finished aluminum cut.

After cutting aluminum, you’ll often find sharp edges and tiny bits called burrs. These can be sneaky little troublemakers! To fix this, grab a file or some sandpaper and smooth those edges. Your fingers will thank you later. For a fancy finish, consider options like anodizing or painting. These treatments not only make your aluminum look snazzy but also help it resist wear and tear. Explore your choices!

| Treatment | Description |

|---|---|

| Anodizing | Creates a durable and colorful surface. |

| Painting | Adds color and prevents corrosion. |

Common Issues and Troubleshooting Tips

Identifying and resolving common problems when cutting aluminum. Maintenance tips for prolonging blade life and bandsaw performance.

Cutting aluminum on a bandsaw can be tricky. Common issues include blade binding and rough cuts. To fix these, check the blade tension and ensure it’s sharp. Regular maintenance helps, too. Here are tips to keep your bandsaw in great shape:

- Always clean the blade after use.

- Check blade tension regularly.

- Use the right cutting speed.

- Lubricate the blade to prevent overheating.

A well-maintained bandsaw cuts smoothly and lasts longer.

What are common problems when cutting aluminum?

Common issues include blade wear and overheating. Using the correct speed and blade type can prevent these problems.

Conclusion

In conclusion, cutting aluminum on a bandsaw is simple with the right techniques. Use a fine-toothed blade for clean cuts. Keep the aluminum steady while cutting to avoid mistakes. Always wear safety gear to protect yourself. Now that you know these tips, grab a bandsaw and practice your skills. For more details, check out guides or videos online!

FAQs

What Type Of Bandsaw Blade Is Best Suited For Cutting Aluminum, And Why?

You should use a blade with fine teeth for cutting aluminum. This type of blade helps you make clean cuts. It also prevents the metal from getting stuck. A bi-metal blade is strong and lasts longer, too. This makes it great for cutting aluminum easily!

How Can You Adjust The Speed And Feed Rate When Cutting Aluminum On A Bandsaw For Optimal Results?

To cut aluminum on a bandsaw, you want to adjust the speed and how fast you push the material. First, set the saw to a higher speed because aluminum cuts best that way. Then, feed the aluminum slowly and steadily. This helps keep the cut smooth and prevents the blade from getting stuck. Always remember to wear safety gear while working!

What Safety Precautions Should Be Taken While Cutting Aluminum On A Bandsaw To Minimize Risks?

When cutting aluminum on a bandsaw, you should always wear safety glasses to protect your eyes. Use gloves to keep your hands safe but make sure they are tight-fitting. Keep your fingers away from the blade while cutting. Make sure the work area is clean and free of clutter. Finally, have an adult help you if you’re unsure about the machine.

How Can You Reduce Burr Formation When Cutting Aluminum On A Bandsaw?

To reduce burrs when cutting aluminum on a bandsaw, you can try a few things. First, use a sharp blade. A dull blade creates more burrs. Second, set the speed to the right level; cutting too fast can cause more rough edges. Finally, use cutting fluid to help the blade slide smoothly. This can keep the metal from getting messy.

What Maintenance Tips Should Be Followed To Ensure A Bandsaw Remains Effective For Cutting Aluminum?

To keep your bandsaw working well for cutting aluminum, you should check the blade often. Make sure it’s sharp and clean. If it gets dull or dirty, you should replace or clean it. Also, keep the machine oiled so the parts move easily. Finally, clean up any metal shavings around the bandsaw after use. This helps it run better!