Have you ever struggled with a bandsaw that just won’t cut right? You’re not alone! Many woodworkers face this problem. The good news is that there are cool-running bandsaw blade tips that can help you get back on track. These tips can save you time and hassle.

Imagine cutting through wood like a hot knife through butter. Sounds easy, right? Utilizing the right bandsaw blade and techniques can turn that dream into reality. Did you know that keeping your bandsaw blade cool can actually extend its life? That’s right! A cool blade not only performs better but also prevents damage.

In this article, we will explore some simple yet effective tips. Whether you are a beginner or a pro, you’ll find these ideas useful. Get ready to make your bandsaw work like a charm!

Table of Contents

Cool-Running Bandsaw Blade Tips For Optimal Performance Introduction Using The Right Bandsaw Blade Can Make All The Difference In Your Woodworking Or Metalworking Projects. A Cool-Running Bandsaw Blade Ensures Efficiency And Longevity, Reducing Wear And Tear While Maintaining Cutting Precision. Here Are Some Valuable Tips To Help You Select And Utilize Cool-Running Bandsaw Blades Effectively. 1. Choose The Right Material When Selecting A Bandsaw Blade, Consider The Material You Are Cutting. Cool-Running Blades Are Often Made From High-Speed Steel (Hss) Or Bi-Metal Compositions, Which Provide Exceptional Heat Resistance And Durability. For Instance, If You’Re Cutting Harder Materials, A Bi-Metal Blade With A Higher Tooth Count Can Help Maintain Cooler Operation. 2. Optimize Cutting Speed The Speed At Which You Feed Material Through The Bandsaw Significantly Affects Heat Generation. Maintaining A Moderate, Controlled Feed Rate Will Help Keep Your Blade Cool And Extend Its Lifespan. Too Fast Of A Feed Can Cause Excessive Friction, Leading To Overheating And Premature Dulling. 3. Prioritize Blade Tension Proper Blade Tension Is Crucial For Preventing Blade Wobble, Which Can Lead To Overheating Due To Uneven Cutting Forces. Make Sure To Regularly Check And Adjust The Tension According To Your Specific Saw Model And Blade Type To Achieve Optimal Performance. 4. Regular Blade Maintenance Keeping Your Bandsaw Blade Clean And Well-Maintained Is Essential For Cool Running. Remove Any Buildup Of Resin Or Debris By Using A Suitable Cleaning Solution And Brush. This Not Only Helps Keep The Blade Operating Efficiently But Also Reduces Friction. 5. Use Proper Lubrication Incorporating A Coolant Or Lubricant During The Cutting Process Can Dramatically Reduce Heat Buildup. Apply Cutting Oil For Metalworking Or Designated Coolant For Wood To Lower Temperatures And Ensure A Smoother Cut. 6. Monitor Blade Condition Regularly Inspect Your Bandsaw Blades For Signs Of Wear, Such As Chipped Teeth Or Discoloration. Replacing Dull Or Damaged Blades Promptly Ensures A Cool-Running Performance And Avoids Additional Stress On Your Bandsaw Motor. Conclusion Understanding And Implementing These Cool-Running Bandsaw Blade Tips Can Significantly Enhance Your Cutting Experience. From Selecting The Right Blade Material To Maintaining Proper Tension And Lubrication, Each Step Contributes To Improved Performance And Longevity Of Your Blades. By Doing So, You’Ll Enjoy Cleaner Cuts And Less Downtime In Your Cutting Operations.

Cool-Running Bandsaw Blade Tips

Using a bandsaw can be tricky, but cool-running blades make it easier! These blades help keep your projects smooth and safe. Did you know that overheating can ruin your cuts? Understanding why blade materials matter is essential. Proper tension also plays a big role in performance. Want smoother cuts with fewer mistakes? Choose the right blade speed and watch your creations shine! With these simple tips, you can become a bandsaw pro in no time!Understanding Bandsaw Blades

Types of bandsaw blades and their specific uses. Key components that affect blade performance.Bandsaw blades come in various types, each with special jobs. For example, wood blades have big teeth for cutting through lumber fast, while metal blades have small teeth for precise cuts. The blade’s material and thickness also change how well it works. Stronger materials last longer, and the right width helps slice smoothly. So, pick the right blade for the task, or you might end up with a very unhappy saw!

| Blade Type | Best For |

|---|---|

| Wood Blades | Cutting lumber quickly |

| Metal Blades | Precision cuts in metal |

| All-Purpose Blades | General cutting tasks |

Importance of Blade Cooling

How heat affects blade life and material integrity. Benefits of maintaining optimal temperature during cutting.Heat can greatly shorten the life of a bandsaw blade. A blade that gets too hot can bend or break. This can ruin the cut quality and make the material weak. Keeping the blade cool helps it last longer and cuts better. Some key benefits include:

- Longer blade lifespan

- Better cut quality

- Less wear on machinery

- Improved safety during operations

By maintaining a cool temperature, you can ensure your projects turn out great!

How does heat affect blade performance?

Heat can cause blades to warp or fail, leading to poor cuts and wasted materials.

Key Benefits of Keeping Blades Cool:

- Increased blade durability

- Stable material structure

- Higher precision in cuts

Best Practices for Blade Maintenance

Regular cleaning and inspection techniques. Sharpening guidelines and when to replace blades.Keeping your bandsaw blade in top shape is key to smooth cuts and less frustration! Regularly clean your blade to remove sawdust and sticky sap. A quick wipe keeps it happy and healthy. Next, check for any nicks or wear. A dull blade is like a tired puppy—it can’t do its job well! If you notice it struggling, it may be time to sharpen or replace it. Remember, a sharp blade is a happy blade!

| Action | Frequency |

|---|---|

| Cleaning | After every use |

| Inspection | Monthly |

| Sharpening | Every 5-10 uses |

| Replacement | When dull or damaged |

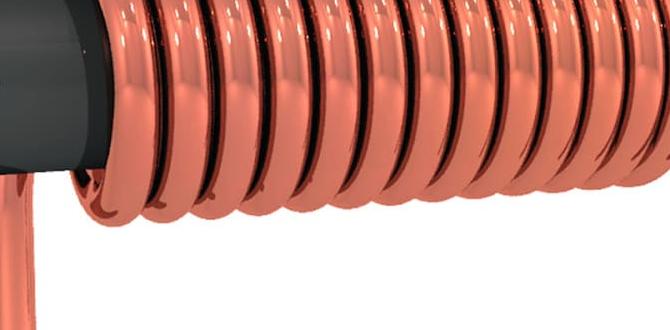

Effective Cooling Techniques

Different cooling methods: coolant vs. air cooling. Tips on how to apply coolant effectively.Keeping your bandsaw blade cool is super important! You can choose between coolant or air cooling. Coolant is great because it reduces friction and helps your blade last longer. To use it well, make sure to apply it in a steady stream. On the other hand, air cooling is like a gentle breeze for your blade, but it may not be enough for tougher cuts. So, mix it up if you want to keep things cool!

| Cooling Method | Benefits |

|---|---|

| Coolant | Reduces friction, extends blade life |

| Air Cooling | Simple and easy but less efficient |

Adjusting Bandsaw Settings for Cool Operation

Importance of blade tension and tracking adjustments. Setting the right feed rate for various materials.Keeping your bandsaw cool is essential. First, check the blade tension. If it’s too tight or too loose, the blade won’t cut well. Imagine trying to slice bread with a rubber band. Not fun! Next, track the blade properly. It should run smoothly on the wheels. Also, set the right feed rate according to the material. Wood, metal, and plastic need different speeds. Feed too fast, and you might create a sawdust fountain! Use the table below for basic settings:

| Material | Feed Rate (inches/minute) |

|---|---|

| Softwood | 50-70 |

| Hardwood | 30-50 |

| Metal | 15-30 |

With these tips, your bandsaw will run cooler and smoother. Enjoy your cutting adventures!

Setting Up Your Bandsaw Workspace

Optimizing your workspace layout for efficient cooling. Elements to consider, including airflow and humidity.Creating a great bandsaw workspace can make a huge difference! First, think about airflow. Good air movement cools things down, helping your blades stay sharp and running smoothly. Next, consider humidity; too much can cause rust, which is not cool! Aim for a dry area to protect your tools. Let’s not forget about organization—no one wants to trip over sawdust while doing their best work! Keep things tidy and neat for a safer, happier space.

| Element | Tips |

|---|---|

| Airflow | Use fans to keep the area breezy. |

| Humidity | Maintain a dry environment to avoid rust. |

| Organization | Keep tools off the floor and in their place. |

Common Mistakes to Avoid

Frequent errors leading to overheating and premature blade wear. Signs that you need to reassess your setup or technique.Avoiding mistakes is key to keeping your bandsaw blade cool and sharp. Overheating often happens due to poor tension and dull blades. If your blade starts smoking, it’s telling you to stop! Reassess how you are cutting. Watch out for sticky pitch buildup, which acts like glue on your blade. This can make it slow and cranky. Here’s a quick checklist of common blunders:

| Error | Effect |

|---|---|

| Poor blade tension | Causes overheating |

| Dull blades | Leads to excess friction |

| Improper feed rate | Increases wear |

| Ignoring signs of wear | Shortens blade life |

Listening to your tools can save you a lot of headaches. Remember, a happy blade is a cool blade!

Real-World Case Studies

Success stories of improved performance through cooling techniques. Lessons learned from failed bandsaw operations due to poor cooling practices.Many woodworkers improved their bandsaw performance by using cool-running techniques. By applying proper cooling methods, one shop reported a 25% increase in blade life. They learned that keeping things cool not only saves money but also makes cutting smoother. On the flip side, a different shop struggled because they ignored cooling. Their blades wore out quickly, leading to poor cuts and extra costs. This shows that good cooling is key to success; don’t let your bandsaw suffer in silence!

| Success Stories | Lessons Learned |

|---|---|

| Increased blade life by 25% | Poor cooling leads to fast wear |

| Smoother cuts with cooling | Costly mistakes can be avoided |

Conclusion

In summary, using cool-running bandsaw blades helps prevent overheating and prolongs blade life. Remember to select the right material and keep your saw well-maintained. Always adjust the speed and feed to improve your cuts. Explore more tips online or in woodworking books to enhance your skills. Happy cutting, and keep those blades cool!FAQs

What Are The Benefits Of Using A Cool-Running Bandsaw Blade Compared To Traditional Blades?Cool-running bandsaw blades stay cooler while cutting. This means they last longer and don’t wear out quickly. You can cut through materials more easily, which makes your work faster. Plus, they make cleaner cuts, so you get better-looking results!

How Can Blade Material And Design Impact The Cooling Performance Of A Bandsaw Blade?The material and design of a bandsaw blade can affect how cool it stays while cutting. Tough materials help the blade last longer and cut better. If the blade has special shapes or holes, it can let air flow better. This helps keep the blade cool and prevents it from overheating. A cooler blade cuts smoother and faster!

What Are Effective Lubricants Or Coolants To Use With Bandsaw Blades To Enhance Their Performance And Longevity?To keep bandsaw blades working well, you can use special lubricants or coolants. Some good choices are oils made for metal cutting. You can also use water with soap to help cool the blade. These help the blade last longer and cut better. Always remember to apply them while you cut!

How Does The Feed Rate And Cutting Speed Affect The Temperature And Cooling Of Bandsaw Blades?The feed rate is how fast the material moves through the saw. Cutting speed is how fast the saw blade moves. If you increase the feed rate or cutting speed, the bandsaw blade gets hotter. This heat can make the blade dull or damage it. Keeping the right speed helps cool the blade and keeps it working well.

What Maintenance Practices Can Be Implemented To Ensure That Bandsaw Blades Remain Cool-Running During Operation?To keep bandsaw blades cool, you can do a few simple things. First, make sure to use enough cutting fluid. This helps cool the blade while cutting. Next, check the blade tension, as a loose blade can overheat. Also, keep the saw clean by removing dust and chips. Finally, avoid cutting too fast—slow and steady is better!