Keep your nail gun working smoothly with this complete guide to maintenance. Simple, essential tips will help you clean, lubricate, and store your tool correctly, preventing jams and extending its life. Master the basics to nail every project with confidence!

Hey there, woodworking pals! Jack Shaffer here, your go-to guy for all things nailers. Ever get that frustrating moment when your trusty nail gun decides to take a break, jamming up right when you’re in the middle of a project? It’s a common headache for DIYers, but the good news is, it’s usually super simple to fix—and even easier to prevent!

Taking a little time to care for your nail gun can save you a lot of headaches and money down the road. You’ll avoid those annoying jams, keep your nails going in straight and true, and make your tool last for years. Think of it like giving your favorite hammer a good polish; it just performs better when it’s looked after.

This guide is all about making nail gun maintenance easy-peasy. We’ll walk through the essential steps, from cleaning and oiling to proper storage, so you can get back to building your dream projects with confidence. Ready to keep your nailer in top shape? Let’s dive in!

Table of Contents

Why Nail Gun Maintenance Matters

Think of your nail gun as a finely tuned machine. Just like a car needs oil changes or a sewing machine needs cleaning, your nail gun performs best when it’s well-maintained. Skipping this simple step can lead to a host of problems that slow you down and can even damage your tool.

When you keep your nail gun clean and properly lubricated, you ensure that all its moving parts work together seamlessly. This means fewer jams, more accurate nail placement, and a smoother operation overall. A well-maintained nail gun is a reliable nail gun, ready to tackle any project you throw at it.

Poor maintenance can result in several issues. Nails might not drive all the way in, or they might bend and jam the mechanism. Dirt and debris can wear down internal components over time, leading to costly repairs or premature replacement. Plus, a gun that’s not firing correctly can be downright dangerous. Regular care isn’t just about performance; it’s about safety and longevity.

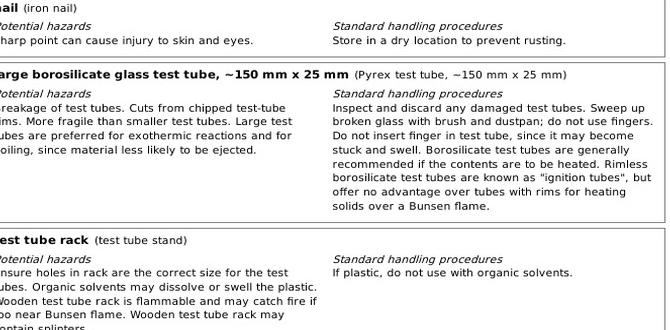

Essential Nail Gun Maintenance Tools & Supplies

Before we get our hands dirty, let’s gather what you’ll need. You don’t need a whole workshop full of fancy equipment for basic nail gun care. Most of what you need is probably already in your home or easily found at a hardware store.

Here’s a quick rundown of the essentials:

- Safety Glasses: Always prioritize safety!

- Gloves: To protect your hands from grease and grime.

- Clean Rags: Lint-free cloths are best for wiping down surfaces.

- Small Brush: An old toothbrush or a dedicated cleaning brush works wonders for nooks and crannies.

- Nail Gun Lubricant: Special oil formulated for pneumatic tools. Check your tool’s manual for recommendations. Mineral oil can sometimes be used, but dedicated nail gun oil is best.

- Compressed Air: For blowing out dust and debris.

- Screwdriver Set: You might need basic screwdrivers for minor disassembly.

- Owner’s Manual: Your best friend for specific instructions for your model!

Having these items ready will make the maintenance process quick and efficient. Remember, consistency is key. A little bit of care regularly goes a long way!

Step-by-Step Nail Gun Maintenance Guide

Now, let’s get to the good stuff! Following these steps will keep your nail gun in great working order. We’ll cover cleaning, lubrication, and a quick check-up.

Step 1: Safety First! Disconnect Power

This is the absolute most crucial step before you do anything else. For pneumatic nail guns, this means disconnecting the air compressor hose. For electric or battery-powered nailers, remove the battery or unplug it from the power source. Seriously, do this first! You don’t want any accidental firing while you’re cleaning or working on the tool.

Check your nail gun’s manual for specific power disconnection instructions. Some guns have safety latches or triggers that need to be engaged. Always double-check that there’s no power connected before proceeding.

Step 2: Clean the Exterior

Start by giving your nail gun a good wipe-down. Use a clean, dry rag to remove any sawdust, dirt, or old lubricant from the outside of the tool. Pay attention to the handle, housing, and any areas where dust tends to accumulate.

For tougher grime, you can slightly dampen your rag with water or a mild degreaser, but be sure to dry it thoroughly afterward. Avoid spraying liquids directly onto the tool, as this can force moisture into sensitive internal parts.

Step 3: Clear the Magazine and Tip

The magazine is where the nails are fed, and the tip is where they exit. These areas are prone to collecting debris that can cause jams.

- Magazine: Open or slide open the nail magazine. Use your brush and a dry rag to clean out any dust, wood shavings, or bent nails that might still be inside. Make sure the nail follower (the part that pushes the nails forward) moves freely.

- Tip/Nose: Look at the very front of your nail gun, where the nail is driven. You might see some residue or debris built up here. Use your brush to gently clean this area. You can also use a burst of compressed air to blow away any loose particles.

It’s a good idea to cycle the driver blade a few times (while still disconnected from power, of course!) to ensure it moves smoothly. If it feels stiff, a little bit of lubricant might be needed, which we’ll do in the next step.

Step 4: Lubricate Moving Parts

This is where your specialized nail gun lubricant comes in. Regular maintenance lubrication is key to keeping the internal mechanisms running smoothly and preventing wear.

For Pneumatic Nail Guns:

Most pneumatic nailers have a small port where you add oil. Check your manual, but usually, you’ll disconnect the air hose, then add a few drops (typically 2-3) of nail gun oil directly into the air inlet port. After adding the oil, reconnect the air hose and fire the tool a few times into scrap wood to distribute the oil throughout the internal mechanism.

For Electric/Cordless Nail Guns:

Maintenance for electric or cordless models can vary more. Some may have a specific lubrication point, while others are designed to be maintenance-free for lubrication purposes (though cleaning is still vital). Refer to your owner’s manual. If it indicates lubrication is needed, follow its specific instructions carefully.

Important Note: Do NOT over-oil. Too much oil can attract dirt and create a gummy residue, which is counterproductive. A little goes a long way.

Step 5: Check the Driver Blade and O-Rings

The driver blade is the part that strikes the nail. If it’s bent, damaged, or not retracting properly, it can cause jams. While you can’t always access this without minor disassembly (which we’ll cover in advanced maintenance), ensure it moves freely when you slide the magazine open or if your tool has a way to manually retract it.

Many tools also have O-rings and seals that can wear out. If your nail gun starts leaking air, it could be a sign of a worn O-ring. These are often replaceable parts and are detailed in your tool’s manual. For basic maintenance, just ensuring everything looks intact is a good start.

Step 6: Reassemble and Test

Once everything is clean and lubricated, reassemble any parts you may have moved. Reconnect the air hose (for pneumatics) or reinsert the battery (for electric/cordless).

Before using it on your project, do a quick test fire into a scrap piece of wood. Listen for any unusual noises and ensure the nails are driving properly. If everything sounds and feels good, your nail gun is ready to go!

Common Nail Gun Problems and How to Fix Them

Even with regular maintenance, occasional hiccups can happen. Here are some common issues and how to troubleshoot them like a pro.

Problem 1: Nail Gun Jamming

This is the most frequent complaint. Jams can happen for several reasons.

- Cause: Debris in the magazine or near the driver blade.

- Fix: Disconnect power. Open the magazine. Carefully remove any jammed nails. Use a brush and compressed air to clean the magazine and the tip. If a nail is deeply lodged, you might need to use pliers or a specialized tool (like a nail puller, though be gentle!).

- Cause: Bent or damaged nails.

- Fix: Ensure you are using the correct type and size of nails recommended for your specific nail gun. Remove any bent nails from the magazine and from the driver mechanism if visible.

- Cause: Lack of lubrication or dirt buildup internally.

- Fix: Perform a thorough cleaning and lubrication as outlined in the steps above.

Problem 2: Nails Not Driving Fully

This is frustrating as it leaves nails proud of the surface, requiring you to hammer them in manually.

- Cause: Low air pressure (pneumatic nail guns).

- Fix: Check your air compressor’s pressure gauge. Ensure it’s set to the recommended PSI for your nail gun (usually found in the manual, often between 70-120 PSI). Also, check that the air hose isn’t kinked.

- Cause: Clogged air filter or regulator.

- Fix: Clean or replace the air filter. Ensure the regulator is functioning correctly.

- Cause: Driver blade sticking or damaged.

- Fix: Clean and lubricate the driver mechanism. If the blade appears bent or damaged, it might need professional service or replacement.

- Cause: Incorrect nail collation angle.

- Fix: Make sure you’re using the right type of nails for your gun. Nail guns fire nails held together at a specific angle (e.g., 15°, 20°, 30°, 34°). Using the wrong angle will cause feeding and firing issues.

Problem 3: Air Leaks

If you hear hissing air when the gun isn’t firing, air is leaking.

- Cause: Loose connections.

- Fix: Ensure the air hose connection at the nail gun is secure.

- Cause: Worn O-rings or seals.

- Fix: This often requires minor disassembly. Consult your owner’s manual for instructions on how to access and replace O-rings or seals, or consider taking it to a service center.

Remember, if you’re ever unsure or dealing with something beyond basic fixes, consulting your owner’s manual or a tool repair professional is always a wise choice. Safety and proper function are paramount!

Storage: Keeping Your Nail Gun Safe

Proper storage is just as important as maintenance for keeping your nail gun in great shape and preventing damage. Think about how you store other tools – a nail gun deserves similar care.

When Not in Use (Short-Term)

- Disconnect the air source or remove the battery.

- Ensure the magazine is empty.

- Store in a dry, clean place, away from extreme temperatures.

- A dedicated tool bag or case is ideal to protect it from dust and damage.

Long-Term Storage

If you won’t be using your nail gun for an extended period (e.g., over winter or between large projects):

- Perform a thorough cleaning and lubrication as described in the maintenance section (Step 4).

- Ensure all parts are dry.

- Lightly spray a rust inhibitor (like WD-40, used sparingly and wiped off excess) on external metal parts to prevent rust, especially on the driver blade if accessible.

- Store in its case or a protective bag in a climate-controlled environment. Avoid damp garages or sheds if possible.

Proper storage prevents dust ingress, corrosion, and accidental damage. It’s a simple habit that pays off in tool longevity.

When to Call a Professional

While most nail gun maintenance is DIY-friendly, some issues are best left to the experts. Don’t hesitate to seek professional help if you encounter any of the following:

- Persistent Jams: If you’ve cleaned and lubricated, and the gun still jams frequently, there might be an internal issue like a bent driver blade carrier or a problem with the firing mechanism.

- Significant Air Leaks: While replacing O-rings can be a DIY task for some, if you’re uncomfortable with disassembly or the leak persists after a seal replacement, a pro can diagnose and fix it.

- Damaged Housing or Critical Components: If the main body of the nail gun is cracked or if a critical internal part appears obviously broken (like the driver blade itself), it’s safer and more effective to have it inspected by a qualified technician.

- Performance Issues You Can’t Diagnose: If your nailer is making strange noises, not firing consistently, or exhibiting other unusual behavior that you can’t resolve with basic maintenance, professional diagnosis is recommended.

Professional repair shops specialize in diagnosing and fixing complex tool problems. They have the proper tools, spare parts, and expertise to get your nail gun back to spec safely and effectively. Sometimes, paying for a repair is more cost-effective than replacing an entire tool, especially for high-quality models. For more information on tool care and safety, resources like OSHA’s guidelines on tools and equipment offer valuable insights into safe operation of power tools.

Types of Nail Guns and Specific Maintenance Notes

While the core maintenance principles are similar, different types of nail guns might have slight variations to consider.

Here’s a quick look:

| Nail Gun Type | Power Source | Key Maintenance Considerations |

|---|---|---|

| Framing Nailer | Pneumatic | Often used for heavy-duty tasks. Requires regular lubrication of the air cylinder. Intake filter needs checking for debris. |

| Brad Nailer / Finish Nailer | Pneumatic, Electric, Battery | Smaller, more delicate. Lubrication is still key. The magazine nose can get clogged easily. Electrical contacts on battery models need to be kept clean. |

| Roofing Nailer | Pneumatic | Exposed to elements more often. Needs thorough exterior cleaning to prevent grit from jamming mechanisms. Ensure the depth adjustment is clean and moves freely. |

| Siding Nailer | Pneumatic | Similar to framing nailers but often lighter duty. Regular lubrication and magazine cleaning are important. |

| Pin Nailer | Pneumatic, Electric, Battery | Very fine nails, very delicate. Prone to jams if not kept perfectly clean and lubricated. Tiny parts may require more precision. |

No matter the type, always refer to your specific model’s owner’s manual. It’s the definitive guide for your tool, listing recommended lubricants, maintenance schedules, and troubleshooting tips tailored to its design.

Air Compressor Maintenance (for Pneumatic Tools)

If you’re using pneumatic nail guns, don’t forget to maintain your air compressor! A well-maintained compressor ensures you have clean, dry air delivered at the right pressure.

- Drain the Tank: Regularly drain the condensation from the air tank. Moisture can travel through the hose and into your nail gun, causing rust and performance issues.

- Check Filters: Clean or replace air filters on the compressor as recommended.

- Check Oil Levels (if applicable): Some compressors require oil. Ensure the oil level is correct.

You can find detailed guides on air compressor maintenance from manufacturers and resources like Tooling Tips (Guide to Maintaining Your Air Compressor) which can help keep your entire pneumatic system running optimally.

Conclusion

There you have it, folks! A complete rundown on how to keep your nail gun in tip-top shape. By incorporating these simple maintenance steps into your routine, you’re not just cleaning a tool; you’re investing in its longevity, reliability, and your own project success.

A well-maintained nail gun means fewer frustrating jams, smoother operation, and more precise nail placement. It’s about enjoying your woodworking and DIY projects without avoidable headaches. So, grab your rags, your oil, and your safety glasses, and give your nailer the care it deserves. You’ll be amazed at how much better it performs and how much longer it lasts.

Happy building, and remember: a little maintenance goes a long way on the path to perfect projects!

Frequently Asked Questions (FAQs)

Q1: How often should I lubricate my nail gun?

For pneumatic nail guns, it’s generally recommended to add 2-3 drops of oil every day of heavy use or weekly if used less frequently. For electric/battery models, always