Have you ever wondered how much a beautiful wood slab costs? Whether you’re crafting a new table or building a shelf, knowing the slab price is key. Calculating the cost of wood slabs can be tricky, but it doesn’t have to be. It’s more than just picking a pretty piece of wood.

Imagine walking into a lumberyard. You see many types of wood, each with different textures and shades. You might ask yourself, “Why does one slab cost so much more than the other?” Understanding how to calculate a wood slab price can help you make better choices.

Did you know that the type of wood, size, and finish all impact the price? For instance, species like oak can be pricier than pine. If you know what factors to consider, you can save money and find the perfect wood slab for your project.

In this article, we will explore how to calculate wood slab price. We will break down the steps to make it easy and fun. Ready to become a wood-slab-savvy shopper?

Table of Contents

How Do You Calculate Wood Slab Price For Your Projects?

Calculating the price of a wood slab involves several simple steps. First, measure the size of the slab in board feet. Then, check the type of wood, as prices vary widely. Don’t forget to consider the slab’s quality and finish. Did you know that rare woods can cost more than gold? By combining these factors, you get a clear idea of how much a wood slab will cost. Happy woodworking!

Factors Influencing Wood Slab Pricing

Discussion of size and thickness influencing cost. Role of wood quality and grade in pricing.

Several factors affect the price of wood slabs. First, the size and thickness significantly influence the cost. Larger and thicker slabs need more wood and take longer to cut. Next, wood quality is crucial. Higher-grade wood with fewer knots is more expensive. This wood looks better and lasts longer. A simple rule to remember is: bigger and better wood means a higher price.

What makes wood slabs more expensive?

Factors like size and quality play key roles in pricing. For example, a thicker slab made from high-quality wood can cost much more than a thinner slab made from lower-quality wood.

| Factor | Impact on Price |

|---|---|

| Size | Increases price with larger dimensions |

| Thickness | Higher costs for thicker slabs |

| Wood Quality | Better quality raises price |

Calculating the Base Price per Board Foot

Explanation of the board foot measurement. Formula for calculating base price based on thickness, width, and length. To find the base price per board foot, first, we need to understand what a board foot is. A board foot is a measurement for lumber. It equals a piece of wood that is one foot long, one foot wide, and one inch thick. To calculate the base price, use this formula:

- Base Price = (Thickness x Width x Length) / 12

For example, if your wood slab is 2 inches thick, 12 inches wide, and 48 inches long, the calculation would look like this:

- Base Price = (2 x 12 x 48) / 12

- Base Price = 96 board feet

By knowing the price per board foot, you can find the total cost. This method helps buyers and sellers agree on fair prices.

How do you find the base price of lumber?

The base price is found using the formula: Base Price = (Thickness x Width x Length) / 12. This will help you calculate the cost of lumber accurately.

Accounting for Kiln Drying and Finishing Costs

Importance of kiln drying in pricing. Additional costs for sanding, sealing, and finishing.

Understanding kiln drying is key to finding the right price for wood slabs. Kiln drying removes moisture, preventing warping and cracking. Without it, your beautiful slab might turn into a sad, twisted piece of wood. Also, there are extra costs for sanding, sealing, and finishing. These steps help make your slab smooth and ready for anything. Think of it as giving your wood slab a spa day—who doesn’t love a good pampering?

| Cost Component | Approximate Cost |

|---|---|

| Kiln Drying | $1.00 – $2.00 per board foot |

| Sanding | $0.50 – $1.50 per board foot |

| Sealing & Finishing | $2.00 – $4.00 per board foot |

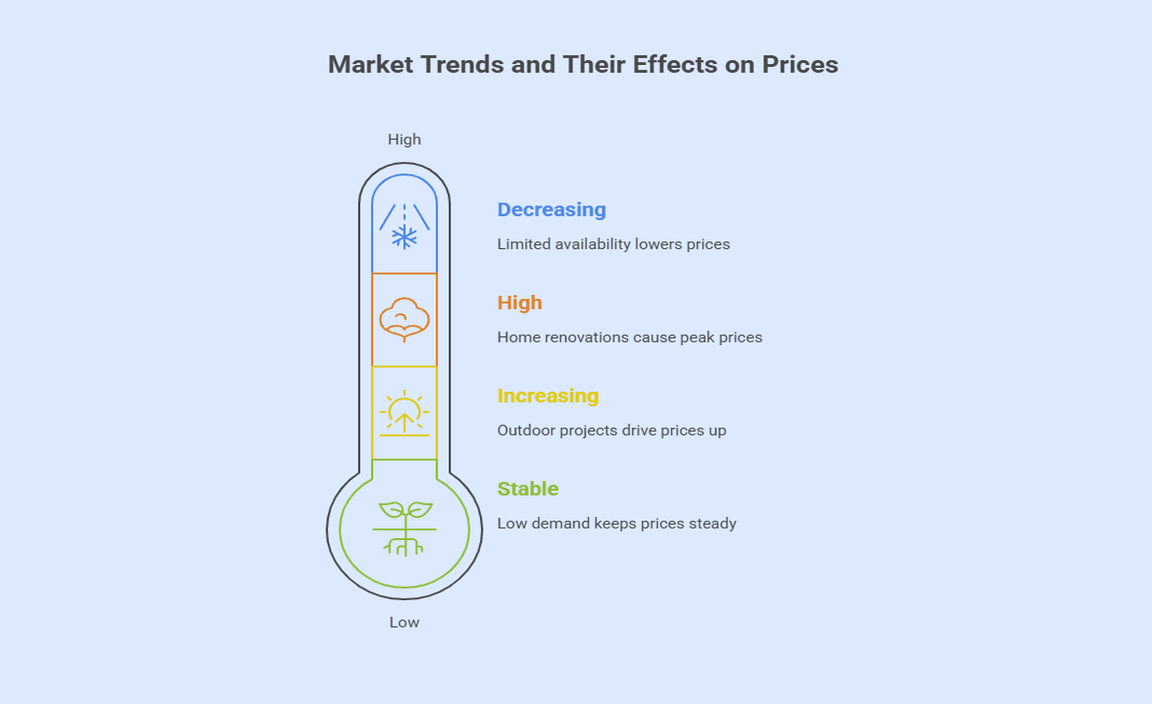

Market Trends and Their Effects on Prices

Analyzing current market demand for wood slabs. Seasonal price fluctuations and their causes. Today, the demand for wood slabs is high. People want them for furniture and crafts. This rising interest can push prices up, making sellers smile. Seasonal changes can also affect prices. For example, prices might rise in fall when many people start home projects. Supply Chain Issues or bad weather can add to these swings. Understanding these trends helps buyers snag the best deals and avoid price bumps!

| Season | Price Trend | Possible Cause |

|---|---|---|

| Spring | Stable | Low demand |

| Summer | Increasing | Outdoor projects |

| Fall | High | Home renovations |

| Winter | Decreasing | Limited availability |

Finding a Reliable Wood Slab Supplier

Tips for sourcing slabs from reputable vendors. Evaluating supplier pricing and quality comparisons.

Choosing the right wood slab supplier is key to a great project. Look for vendors with good reviews. Ask friends or check online ratings. Don’t settle for the first choice. Always compare prices and quality.

- Check if they offer samples.

- Review their wood types and sizes.

- Ask about their sourcing methods.

Reliable suppliers may charge a bit more, but you get better quality. This can save money in the long run. Remember, quality wood lasts longer!

How can you find high-quality wood suppliers?

To find high-quality wood suppliers, you can check local markets and ask for recommendations. Online platforms and niche forums also help connect with trusted vendors.

DIY vs. Professional Pricing Breakdown

Cost difference between DIY wood slab projects and hiring professionals. Pros and cons to consider for each option.

Choosing between DIY projects and hiring a professional can be tough. DIY can save money (around 30-50% cheaper), but it requires time and skill. On the other hand, professionals guarantee quality and save you effort but come with a higher price tag. Here’s a quick breakdown:

- DIY

- Lower cost

- Control over project

- Requires tools and know-how

- Professional

- Higher cost

- Expert craftsmanship

- No work for you

What is typically cheaper, DIY or hiring a pro?

DIY is usually cheaper. Most people can save 30-50% by doing it themselves, but they need the tools and skills to finish the project.

Calculating Shipping and Handling Fees

Factors affecting shipping costs for large wood slabs. Strategies for minimizing shipping expenses.

Shipping costs for large wood slabs depend on several factors. These include the slab’s size, weight, and distance to travel. Large slabs may cost more to ship due to their size.

To minimize shipping expenses, consider these strategies:

- Choose local suppliers to save on long-distance charges.

- Use a flat-rate shipping service if possible.

- Combine items in one shipment.

Planning ahead can make shipping more affordable!

What factors affect shipping costs for large wood slabs?

Size, weight, and distance are key factors in determining shipping costs. The larger and heavier the slab, the higher the shipping charge.

How can you minimize shipping expenses?

- Shop local.

- Look for flat-rate options.

- Bundle shipments.

Comparative Analysis of Competitor Pricing

Reviewing competitor pricing strategies. How to position your pricing competitively in the market.

Understanding what others charge can help you set your prices right. Look closely at how competitors price their wood slabs. You might notice some offer discounts or special deals. Make sure to catch those sneaky sales—it’s like catching your favorite snack on sale! Use an organized table for comparison.

| Competitor | Price per Slab | Discounts |

|---|---|---|

| Wood Wonders | $50 | 10% off for first-time buyers |

| Slab City | $45 | Free delivery over $100 |

| Rustic Roots | $55 | No discounts |

Your goal is to stay competitive and grab attention. See where you can fit in the market. Remember, pricing too high might scare off customers, while pricing too low might make them think you’re selling plywood! Striking the right balance is key.

Conclusion

Calculating wood slab prices involves considering size, type, and quality. First, measure your slab and find the species costs. Check local prices for similar slabs. Consider unique features like knots or color. Now you know the basics! If you’re ready, research more about specific woods or visit a local lumberyard for firsthand experience. Happy slab hunting!

FAQs

What Are The Key Factors That Influence The Price Of A Wood Slab?

The price of a wood slab depends on several key factors. First, the type of wood matters. Some woods, like oak and walnut, cost more. Second, the size of the slab is important. Bigger slabs usually cost more money. Finally, if the wood is rare or hard to find, the price goes up too.

How Can I Determine The Volume Of A Wood Slab To Calculate Its Price Accurately?

To find the volume of a wood slab, first measure its length, width, and thickness. Use a ruler or tape measure. Then, multiply these three numbers together. For example, if the slab is 2 feet long, 1 foot wide, and 0.5 feet thick, the volume is 1 cubic foot (2 x 1 x 0.5 = 1). Now you can use this volume to help figure out the price!

What Is The Impact Of Wood Species On The Pricing Of Slabs?

Different types of wood, or wood species, can change how much slabs cost. Some woods, like oak and walnut, are more expensive. They are harder to find and look nicer. Other woods, like pine, are cheaper because they grow faster. So, the wood species really affects the price of slabs you might buy.

How Do Market Trends And Availability Affect The Cost Of Hardwood Slabs?

Market trends and availability can change the price of hardwood slabs. When many people want slabs, prices go up. If there are many slabs available, prices usually go down. We pay more when wood is hard to find. So, supply and demand help decide how much we pay for hardwood slabs.

Are There Specific Formulas Or Standard Pricing Guidelines Used In The Lumber Industry To Estimate Wood Slab Prices?

Yes, there are ways to estimate prices for wood slabs. First, we look at the type of wood. Then, we consider the size and thickness of the slab. It helps to check prices from local sellers or online to see what others charge. Using these factors, you can get a good idea of what a wood slab should cost.

Resource:

board foot calculator tool: https://www.woodweb.com/cgi-bin/calculators/calc.pl

understanding hardwood species: https://www.wood-database.com/wood-articles/wood-species-comparison-chart/

lumber drying process explained: https://www.fpl.fs.usda.gov/documnts/fplgtr/fplgtr117.pdf

lumber market trends overview: https://www.randomlengths.com/