Have you ever wondered how woodworkers achieve that perfect cut? One key factor is using the right blade tensioning tools for bandsaws. These tools help keep the bandsaw blade tight, allowing for clean and precise slicing.

Imagine cutting through thick wood like butter. Sounds amazing, right? This is possible when your bandsaw is set up correctly, and blade tensioning plays a huge role. If the blade is too loose, it can wander off your marked line. This could ruin your project!

Many might not think about it, but the tension of the blade can make or break your work. Fun fact: a well-tensioned bandsaw blade can last longer and perform better! Investing in the right blade tensioning tools can save time and frustration.

So, what should you know about these tools? Let’s explore how they work and why they matter. Get ready to discover the secrets behind that smooth and straight cut!

Table of Contents

Essential Blade Tensioning Tools For Bandsaws Explained

Blade Tensioning Tools for Bandsaws

Blade tensioning tools are essential for bandsaw users. Proper tensioning keeps the blade strong and straight. Did you know that a loose blade can cause dangerous kickback? With the right tools, you can easily adjust blade tension to improve cuts and extend blade life. These tools help you measure tension accurately for different types of materials. You’ll enjoy smoother operations and better results, making your woodworking projects even more enjoyable!Understanding Blade Tensioning

Importance of proper blade tension in bandsaw performance. Effects of inadequate tension on cutting quality and blade lifespan.Getting the blade tension right is key for your bandsaw. If the tension is too slack, the saw can wander off course like a lost puppy! This can lead to jagged cuts and a shorter blade life. An *improperly tensioned blade* is like trying to ride a bicycle with flat tires—it just won’t work well. On the flip side, the perfect tension keeps your cuts straight and your blade happy. Remember, a well-tensioned blade is a happy blade!

| Importance of Proper Tension | Effects of Inadequate Tension |

|---|---|

| Improves cut accuracy | Creates jagged cuts |

| Increases blade lifespan | Shortens blade life |

| Supports better performance | Causes blade wander |

How to Choose the Right Blade Tensioning Tool

Considerations for bandsaw size and type. Factors influencing tool accuracy and ease of use.Choosing the right blade tensioning tool is like picking the best ice cream flavor; it’s all about preference! First, think about your bandsaw size and type. Some tools fit only specific bandsaws. Others can do more, but watch out! Not all tools are as accurate as a squirrel with a GPS. Look for tools that are easy to use; an intuitive design saves time and keeps your fingers safe. Let’s break it down:

| Consideration | Details |

|---|---|

| Bandsaw Size | Choose a tool that fits your bandsaw’s size. |

| Tool Accuracy | Look for tools known for their precision. |

| Ease of Use | Consider tools with straightforward designs. |

You’ll find the right tensioning tool before you can say “bandsaw!” Remember, the right choice makes all the difference in your woodworking adventures!

Step-by-Step Guide to Tensioning Bandsaw Blades

Preparation and setup before tensioning. Detailed instructions on using tensioning tools effectively.Before you start tensioning bandsaw blades, get everything ready. First, check your bandsaw and ensure it is clean and free from debris. Next, gather your blade tensioning tools for bandsaws. It is crucial to have the right tools for the job. Lastly, ensure the blade is installed correctly on the wheel. Follow these quick steps for effective tensioning:

- Turn off the bandsaw and unplug it.

- Use the tensioning tool to set the proper tension.

- Check the tension with a gauge if you have one.

- Test the blade by rotating it and listening for noises.

Using these steps will help you tension your bandsaw blade effectively.

How to Use Blade Tensioning Tools?

To use blade tensioning tools, align the tool with the blade and adjust until you reach the desired tension. Ensure the blade is straight and properly seated in the wheels for the best results.

Common Issues and Troubleshooting

Diagnosing blade tension problems. Solutions for common tensioning mistakes.Blade tension problems can be sneaky. When the tension is off, your bandsaw won’t cut straight, and that’s no fun at all! A common sign is a strange noise. If your blade feels loose, it’s time for some quick troubleshooting. Always check if it’s too tight or too loose—kind of like a pair of socks that are too small! Here are solutions for common tensioning mistakes:

| Issue | Solution |

|---|---|

| Too loose | Increase tension slowly until right. |

| Too tight | Loosen just a bit to prevent damage. |

| Wobbly cuts | Re-check and adjust tension carefully. |

Remember, keeping your blade happy means happy cuts!

Maintenance and Care for Tensioning Tools

Best practices for maintaining blade tensioning tools. Tips for prolonging the lifespan of your tools.Taking good care of your tools helps them last longer and work better. Here are some best practices for maintaining blade tensioning tools:

- Always keep your tools clean. Dirt can cause problems.

- Check for wear and tear regularly. Fix any issues quickly.

- Store tools in a dry place to prevent rust.

- Use the right amount of tension for your blade.

- Follow the manufacturer’s instructions for use and care.

With these tips, your tensioning tools will serve you well for years to come!

How can I use blade tensioning tools effectively?

To use blade tensioning tools effectively, read the manual carefully. Adjust tension according to the blade type for best results.

Tips for maintaining tools:

- Inspect tools before each use.

- Lubricate moving parts as needed.

- Keep them in a tool case to avoid damage.

Top Brands and Products in Blade Tensioning Tools

Review of popular brands and their features. Comparison of customer reviews and professional recommendations.Many brands make excellent blade tensioning tools for bandsaws. Each brand offers unique features that help woodworkers. Some popular brands are:

- Park Tool: Known for durability and precision.

- SawStop: Great technology for safety and efficiency.

- Jet: Offers easy-to-use tools with good customer support.

Customers love these brands for their reliability. Professionals often recommend them for their high performance. Reviews highlight how these tools make cutting easier and safer. Users appreciate smooth operation and easy adjustments.

What features should you look for in blade tensioning tools?

Key features include:

- Easy adjustment: Tools should allow for quick tension changes.

- Durability: Look for strong materials that last.

- Accurate measurements: Precision helps maintain blade performance.

These aspects enhance your bandsaw experience and improve your work quality.

Real-World Applications and Case Studies

Practical examples of effective blade tensioning in various industries. Insights from experienced woodworkers and fabricators on tool effectiveness.Many industries rely on effective blade tensioning for bandsaws. Woodworkers find these tools essential for smooth cuts. For example, carpenters report better accuracy with blade tensioning tools. This is crucial in furniture making. Fabricators also use these tools to enhance production speed. A local shop noticed a 20% boost in efficiency after using advanced tensioning methods. Here are some insights:

- Improved cut quality

- Reduced blade wear

- Increased safety while cutting

Why is blade tensioning important?

Blade tensioning keeps the blades tight, which leads to better, safer cuts.Conclusion

In conclusion, blade tensioning tools for bandsaws are essential for better cuts and improved safety. Proper tension keeps blades straight and prevents breakage. Using these tools helps you maintain your bandsaw effectively. So, check your blade tension regularly. For more tips on using bandsaws, explore additional resources or guides. Happy woodworking!FAQs

Sure! Here Are Five Related Questions About Blade Tensioning Tools For Bandsaws:Sure! Blade tensioning tools help tighten and loosen the blade on a bandsaw. This makes sure the blade cuts straight and stays safe. When the blade is tight enough, it works better. If it’s too loose, the cuts might be crooked. You can use these tools to adjust the blade easily!

Sure! Please share the question you’d like me to answer, and I’ll do my best to help you.

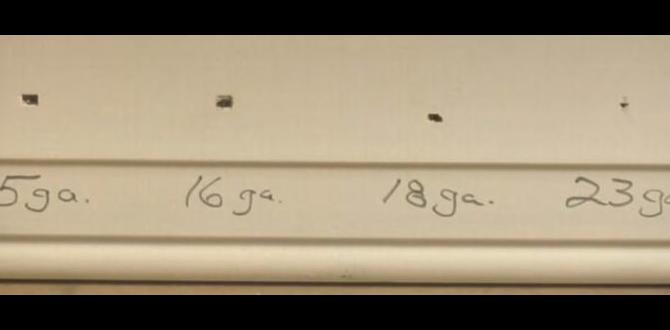

What Are The Different Types Of Blade Tensioning Tools Available For Bandsaws, And How Do They Differ In Functionality?There are a few types of blade tensioning tools for bandsaws. One type is a manual tensioner, which you turn by hand. Another type is a lever tensioner, which you pull down to tighten the blade. Some bandsaws even have automatic tensioners that adjust themselves. Each tool helps you keep the blade tight for better cutting.

How Do You Properly Calibrate A Blade Tensioning Tool To Ensure Optimal Performance Of A Bandsaw Blade?To calibrate a blade tensioning tool, first, make sure the bandsaw is turned off. Then, check the blade for any twists or bends. You can use the tensioning tool to adjust the tightness of the blade. Turn the tool until the blade feels firm but not too tight. Finally, check if the blade runs straight when you turn on the bandsaw.

What Are The Signs That Indicate A Bandsaw Blade May Require Re-Tensioning, And How Can A Tensioning Tool Assist In This Process?You might need to re-tension your bandsaw blade if it starts to make weird noises or cuts unevenly. If the blade looks wobbly or loose, that’s a sign too. A tensioning tool helps you tighten the blade to the right level. This makes the blade work better and keeps your cuts straight. Using the tool is easy and helps keep your saw safe!

Are There Any Specific Maintenance Tips For Blade Tensioning Tools To Ensure Their Longevity And Accuracy?To keep your blade tensioning tools working well, always clean them after use. Make sure to store them in a dry place. Check for any damage or wear regularly. You can also lightly oil moving parts to keep them working smoothly. Doing these things helps your tools last longer and stay accurate!

How Does Blade Tension Impact The Overall Cutting Performance And Life Expectancy Of A Bandsaw Blade?Blade tension is how tight or loose the bandsaw blade is. If the blade is too loose, it can wobble and cut poorly. When the blade is tight, it cuts straight and smoothly, helping it last longer. Good tension means better cuts and a longer life for the blade. So, we need to check the tension often for the best results!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions About Blade Tensioning Tools For Bandsaws:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Blade tensioning tools help tighten and loosen the blade on a bandsaw. This makes sure the blade cuts straight and stays safe. When the blade is tight enough, it works better. If it’s too loose, the cuts might be crooked. You can use these tools to adjust the blade easily!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer, and I’ll do my best to help you.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Blade Tensioning Tools Available For Bandsaws, And How Do They Differ In Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are a few types of blade tensioning tools for bandsaws. One type is a manual tensioner, which you turn by hand. Another type is a lever tensioner, which you pull down to tighten the blade. Some bandsaws even have automatic tensioners that adjust themselves. Each tool helps you keep the blade tight for better cutting.”}},{“@type”: “Question”,”name”: “How Do You Properly Calibrate A Blade Tensioning Tool To Ensure Optimal Performance Of A Bandsaw Blade?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate a blade tensioning tool, first, make sure the bandsaw is turned off. Then, check the blade for any twists or bends. You can use the tensioning tool to adjust the tightness of the blade. Turn the tool until the blade feels firm but not too tight. Finally, check if the blade runs straight when you turn on the bandsaw.”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate A Bandsaw Blade May Require Re-Tensioning, And How Can A Tensioning Tool Assist In This Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might need to re-tension your bandsaw blade if it starts to make weird noises or cuts unevenly. If the blade looks wobbly or loose, that’s a sign too. A tensioning tool helps you tighten the blade to the right level. This makes the blade work better and keeps your cuts straight. Using the tool is easy and helps keep your saw safe!”}},{“@type”: “Question”,”name”: “Are There Any Specific Maintenance Tips For Blade Tensioning Tools To Ensure Their Longevity And Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your blade tensioning tools working well, always clean them after use. Make sure to store them in a dry place. Check for any damage or wear regularly. You can also lightly oil moving parts to keep them working smoothly. Doing these things helps your tools last longer and stay accurate!”}},{“@type”: “Question”,”name”: “How Does Blade Tension Impact The Overall Cutting Performance And Life Expectancy Of A Bandsaw Blade?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Blade tension is how tight or loose the bandsaw blade is. If the blade is too loose, it can wobble and cut poorly. When the blade is tight, it cuts straight and smoothly, helping it last longer. Good tension means better cuts and a longer life for the blade. So, we need to check the tension often for the best results!”}}]}