Have you ever wondered how to make precise cuts with narrow blades? It can feel tricky. The secret lies in using the right blade guides for narrow blades. These guides help keep blades steady, making it easier to create clean lines.

Imagine cutting a piece of wood for your next big project. You want it to look perfect, right? But what if your blade wobbles? That’s where good blade guides come into play. They keep everything aligned and help you avoid those messy mistakes.

Here’s a fun fact: Did you know that even the best woodworkers rely on blade guides? Without them, their cuts could end up crooked. Blade guides not only improve accuracy but also boost confidence while working.

In this article, you’ll discover the best options for blade guides designed specifically for narrow blades. Let’s get cutting!

Table of Contents

Essential Blade Guides For Narrow Blades: A Comprehensive Guide

Blade Guides for Narrow Blades

Choosing the right blade guides for narrow blades is key to smooth cuts. These guides keep the blade straight and reduce wobbling. Have you ever noticed how a crooked cut can ruin a project? A good guide helps maintain accuracy. Many guides offer adjustments for different blade sizes, ensuring versatility. Here’s a fun fact: Properly set guides can also prolong the life of your blades. With the right tools, even tricky cuts become a breeze!Understanding Blade Guides

Definition and purpose of blade guides. Importance of blade guides for narrow blades.Blade guides are important tools in woodworking. They help keep narrow blades on track while cutting. This makes your cuts clean and precise. Without blade guides, blades can wobble or bend. This can cause rough edges and accidents. For narrow blades, guides support the blade better. They prevent bending and improve safety. Using the right blade guide means better work and safer projects.

What are blade guides used for?

Blade guides help keep blades steady and aligned while cutting. They support narrow blades to make straight, smooth cuts without any wobbling.

Benefits of blade guides:

- Improves cutting accuracy

- Enhances safety during use

- Reduces blade wear and tear

Types of Blade Guides for Narrow Blades

Roller guides: Features and advantages. Block guides: Characteristics and uses.There are two popular types of guides for narrow blades: roller guides and block guides. Roller guides are like the cool kids at school. They help blades move smoothly and reduce friction, making cutting easier. They are great for tight turns too! On the other hand, block guides are more straightforward, providing solid support. They keep the blade in place, which is perfect for straight cuts. Think of them as the reliable friend you can always count on!

| Guide Type | Features | Advantages |

|---|---|---|

| Roller Guides | Smooth movement, less friction | Great for curves and tricky cuts |

| Block Guides | Stable support, easy to use | Perfect for straight cuts |

Both guides have their own benefits, so choose wisely based on your cutting adventures. Remember, a good guide can be the difference between a masterpiece and a messy project!

Choosing the Right Blade Guide

Factors to consider when selecting a blade guide. Compatibility with different narrow blade types.Finding the right blade guide can be a bit tricky, but it’s super important! First up, you need to think about compatibility. Not all blade guides work with narrow blades, so check if it fits your specific type. Next, consider the materials. A sturdy guide can make slicing feel easier, sort of like a superhero for your saw! Lastly, think about ease of use. A good guide should be simple to adjust; after all, no one wants to wrestle with their tools like they’re in a wrestling match!

| Blade Type | Compatible Guides |

|---|---|

| Narrow Bandsaw Blades | Fixed and Adjustable Guides |

| Scroll Saw Blades | Precision Guides |

| Dowel Cutting Blades | Movable Guides |

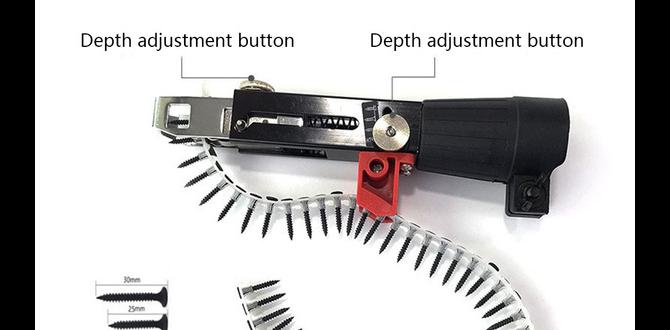

Installation and Setup of Blade Guides

Stepbystep installation process. Common mistakes to avoid during setup.Installing blade guides is easier than it seems. Follow these simple steps:

- Start by gathering your tools. You’ll need a screwdriver and a wrench.

- Remove existing guides if necessary. Clear the area for new installation.

- Attach the new blade guides securely. Make sure they fit the narrow blade snugly.

- Adjust the guides so they align perfectly with the blade.

- Finally, double-check everything to ensure it’s tight and straight.

Watch out for these common mistakes:

- Don’t overtighten screws. It can damage the guides.

- Ensure the guides are straight. Misalignment can cause cutting problems.

- Check for debris. Dirty guides may affect performance.

What are common errors during blade guide installation?

Common errors include improper alignment and using the wrong tools. Ensuring everything is straight and secure helps your cuts remain smooth.

Maintenance Tips for Blade Guides

Regular inspection and cleaning routines. How to troubleshoot and resolve common issues.Keeping your blade guides in shape is easier than you might think! First, do regular inspections. Check for dirt and wear. If you see a buildup, clean it up like you would with spaghetti sauce on your favorite shirt—immediately! Then, troubleshoot issues with simple fixes. If your blade is not tracking well, adjust the guides slightly. A little tweak can make a big difference, just like finding the perfect spot for a rooster’s crow—right outside your neighbor’s window!

| Tip | Action |

|---|---|

| Inspect regularly | Look for dirt or wear |

| Clean often | Remove buildup |

| Troubleshoot | Adjust guides if blades misalign |

Benefits of Using High-Quality Blade Guides

Enhanced precision and control during cutting. Increased longevity and performance of narrow blades.Using high-quality blade guides offers many perks. First, they boost your cutting precision and control. It’s like having a personal assistant who keeps your blade on the right track. Your cuts will be as straight as an arrow (and you won’t need a ruler to measure!).

Moreover, these guides help narrow blades last longer. They’re like cozy pajamas for your tools, keeping them comfy and performing well. With less wear and tear, your blades are ready for all sorts of projects, big or small. So, invest in quality guides, and watch your cuts improve while your blades smile with longevity!

| Benefits | Description |

|---|---|

| Enhanced Precision | Better control leads to straighter cuts. |

| Increased Longevity | Quality guides help blades last longer. |

Common Applications for Narrow Blades and Their Guides

Woodworking projects. Metalworking and other industry applications.Narrow blades are like the superheroes of woodworking and metalworking. In woodworking, they slice through thin shapes, helping create everything from delicate furniture to intricate carvings. In metalworking, these blades cut with precision, shaping metal into useful tools or art pieces. With the right blade guides, you get steady results, ensuring each cut is smooth. After all, nobody wants wobbly cuts that look like a toddler tried to draw! Check out the applications:

| Application | Description |

|---|---|

| Woodworking | Creating furniture, intricate carvings, and detailed joinery. |

| Metalworking | Shaping metal into tools or artistic structures. |

| Other Industries | Used in crafting, repair shops, and production lines. |

Consumer Reviews and Ratings

Summary of user experiences with different blade guides. Analysis of the most rated products for narrow blades.Many users share their experiences with different blade guides for narrow blades. They often highlight how these guides improved their cutting accuracy. Here are some key points:

- Improved stability during cuts.

- Easy to install and adjust.

- Helped reduce blade wandering.

The most rated products often receive praise for their durability and effectiveness. Reviews show that people are happy with guides that make precise cuts easier. Overall, user feedback is valuable for choosing the right blade guides.

What do customers say about the best blade guides?

Many customers report satisfaction with products that enhance their cutting experience. The most liked blade guides are noted for reliable performance and ease of use.

Conclusion

In summary, blade guides for narrow blades help keep your cuts straight and precise. They provide stability and control while working. You should always choose the right guide for your specific project. Try experimenting with different guides to see what works best for you. For more tips and tricks, check out additional resources on blade guides!FAQs

What Are The Key Features To Consider When Choosing Blade Guides For Narrow Blades?When choosing blade guides for narrow blades, you should look for a few important features. First, make sure they fit your blade size. Good guides should hold the blade steady without wiggling. Check if they are easy to adjust and change when needed. Finally, see if they are made from strong materials that won’t wear out quickly.

How Do Different Types Of Blade Guides Affect The Performance And Precision Of Narrow Blades?Blade guides help keep narrow blades steady while you cut. Different types hold the blade in different ways. Some guides make it easier to cut smoothly and accurately. If the blade wobbles, your cut might not be straight. Good guides can help you make better cuts every time!

What Materials Are Commonly Used For Manufacturing Blade Guides For Narrow Blades, And How Do They Impact Durability?Blade guides for narrow blades are often made from materials like plastic, metal, or rubber. Plastic is lightweight and cheap but can wear out quickly. Metal is strong and lasts a long time, making it a great choice for heavy use. Rubber helps reduce noise and can also last a while. Choosing the right material helps the guides stay durable and work better for longer.

Can You Explain The Installation Process For Blade Guides On Narrow Band Saws, And What Common Challenges To Expect?First, we need to turn off the band saw and unplug it for safety. Next, we can remove the old blade guides by unscrewing them. Then, we can place the new blade guides in the right spot and screw them in tightly. Make sure everything is lined up straight. A common challenge is getting the guides to fit just right so the blade moves smoothly. Sometimes, adjusting them can take a bit of time.

How Do Blade Guides Contribute To Blade Alignment And Stability During Operation With Narrow Blades?Blade guides help keep narrow blades straight and steady when cutting. They hold the blade in place, so it doesn’t wobble. This makes cutting safer and more accurate. When the blade is aligned well, you get better results and can finish your work faster. So, using blade guides is really important for good cutting!