Have you ever struggled with a dull bandsaw blade? It can make woodworking tasks frustrating. A sharp blade is key for clean cuts. But when should you change it? Do you know the best tips for blade change? Knowing how to change a blade can save you time and keep your projects running smoothly.

Imagine a project that’s going perfectly until your bandsaw blade starts to tear instead of cut. This common problem can slow you down and ruin your work. But fear not! With a few simple blade change tips, you can keep your bandsaw in top shape.

Did you know that even a small change in how you use the blade can make a big difference? Understanding the right time to change your blade is essential. It helps not only your saw but also your wood and your safety. Let’s dive into these tips and get your bandsaw back on track!

Table of Contents

Essential Blade Change Tips For Bandsaws You Must Know When It Comes To Maintaining The Efficiency And Performance Of Your Bandsaw, Regular Blade Changes Are Crucial. Familiarizing Yourself With The Best Practices Can Save You Time And Improve Your Cutting Results. Here, We’Ll Share Valuable Blade Change Tips For Bandsaws To Ensure You Handle This Process With Ease And Expertise. 1. Safety First Before Starting Your Blade Change, Always Prioritize Safety. Disconnect The Power Supply And Wear Appropriate Protective Gear, Including Gloves And Safety Goggles. This Will Help Prevent Accidents During The Change Process. 2. Choose The Right Blade Selecting The Right Blade For Your Specific Application Can Significantly Affect The Quality Of Your Cut. Consider Factors Such As Material Type, Thickness, And Desired Finish. Bandsaw Blades Come In Various Tooth Configurations, So Ensure You Choose One That Best Fits Your Project. 3. Prepare Your Bandsaw Before You Change The Blade, Ensure The Bandsaw Is Clean And Free Of Debris. Check The Guides And Rollers For Wear, As They Can Affect Blade Performance. Proper Maintenance Of Your Bandsaw Will Enhance Its Lifespan And Efficiency. 4. Remove The Old Blade Carefully Unlock The Tension On The Old Blade To Prevent It From Snapping. Use Appropriate Tools To Loosen The Blade’S Tension Before Disengaging It From The Wheels. It’S Important To Handle The Blade With Care, As It May Remain Sharp And Can Cause Injury. 5. Installing The New Blade When Installing The New Blade, Make Sure It Is Oriented Correctly. Ensure That The Teeth Are Pointed In The Right Direction And That The Blade Fits Snugly Between The Wheels Without Any Twists. Remember To Adjust The Tension According To The Manufacturer’S Specifications. 6. Align The Blade Properly After Installation, It’S Crucial To Align The Blade Correctly. Adjust The Guides And Ensure The Blade Runs True To Avoid Bending Or Premature Wear. Misalignment Can Affect The Accuracy Of Cuts And Damage Both The Blade And The Bandsaw. 7. Test The Bandsaw Once The New Blade Is Installed And Aligned, Run A Test Cut On Scrap Material. This Will Allow You To Assess The Blade’S Performance And Make Any Necessary Adjustments. Ensure That The Bandsaw Runs Smoothly Without Unusual Noise Or Vibration. 8. Keep A Blade Maintenance Schedule Regular Monitoring And Maintenance Of Your Bandsaw Blades Are Essential. Implement A Schedule For Checking The Condition Of Your Blades And Replacing Them As Needed. Keeping An Eye On Blade Wear Will Enhance Your Cutting Quality And Efficiency In The Long Run. Conclusion By Following These Blade Change Tips For Bandsaws, You Can Ensure A Smoother And Safer Process. Proper Blade Maintenance Not Only Extends The Life Of Your Bandsaw But Also Enhances The Quality Of Your Cuts. Remember, A Well-Maintained Bandsaw Is A Key Tool In Achieving Precision In Your Woodworking Projects.

Blade Change Tips for Bandsaws

Changing blades on a bandsaw can seem tricky, but it doesn’t have to be! First, always turn off the saw and unplug it before starting. Make sure to wear safety gear too. Did you know that using the right blade for the job can make a huge difference? Choose a blade that matches the material you’re cutting. Lastly, properly tensioning and tracking the blade can save you from frustrating problems later. Happy woodworking!Understanding Bandsaw Blades

Different types of bandsaw blades and their specific uses. Importance of blade selection for various materials.Bandsaw blades come in various types, each perfect for different tasks. For example, wide blades are great for cutting thick wood, while narrow blades shine when making tight curves. Choosing the right blade is super important! Using the wrong blade on materials can lead to bad cuts or even broken blades. Remember, a blade that laughs at wood might cry over metal!

| Blade Type | Best For |

|---|---|

| Wood Blades | Soft & Hardwoods |

| Metal Blades | Cutting Metal |

| Composite Blades | Plastic & Other Composites |

Choosing wisely can save you time and headaches. So remember, the right blade makes all the difference—just like wearing a cape makes you a superhero!

When to Change Your Bandsaw Blade

Signs that indicate a blade needs replacement. Consequences of using a dull or damaged blade.Knowing when to swap out your bandsaw blade is crucial. Look for these signs:

- If the cuts are rough or uneven.

- Strange noises while cutting.

- Excessive smoke or burning smell.

Using a dull or damaged blade can lead to problems. It can cause:

- Less accurate cuts.

- Increased risk of accidents.

- Damage to your bandsaw.

Stay safe and work smart by checking your blade regularly!

How can you tell if a bandsaw blade is dull?

Check for signs like rough edges, burning smell, or loud sounds. These mean it’s time for a new blade!

Gathering the Right Tools and Materials

Essential tools for changing a bandsaw blade. Recommended blade options and suppliers.To tackle a bandsaw blade change, you need a few essential tools. First, grab a socket wrench. It helps you loosen and tighten the blade. Next, have a measuring tape handy to ensure the new blade is the right size. Don’t forget a set of safety goggles; no one wants sawdust in their eyes! You can also consider a blade clamp for easier handling. For blade options, I recommend brands like Timber Wolf and Olomana. They have great quality, just like a superhero for your saw!

| Tool | Use |

|---|---|

| Socket Wrench | Loosen/tighten blade |

| Measuring Tape | Check blade size |

| Safety Goggles | Protect eyes |

| Blade Clamp | Hold the blade |

With these tools, you’re all set! Remember, a well-changed blade can make you the hero of your workshop.

Step-by-Step Blade Change Process

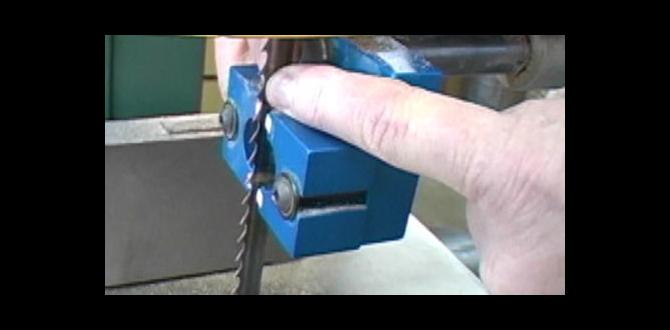

Safe powerdown procedures before starting the change. Detailed guide on removing the old blade.Before changing the blade, make sure to turn off the bandsaw and unplug it. This keeps everyone safe. Then, check that all parts are cool and avoid any moving parts. To remove the old blade, follow these steps:

- Loosen the tension on the blade using the tension knob.

- Slide the blade off the wheels carefully.

- Check for any damage on the wheels before you install the new blade.

Taking time to do this correctly will help keep your bandsaw running smoothly.

Why is it important to power down the bandsaw before changing the blade?

Turning off the bandsaw prevents accidents and keeps users safe from injuries. It’s crucial for protecting fingers and hands from moving parts.

Installing the New Bandsaw Blade

Correct positioning and alignment techniques. Tensioning the blade for optimal performance.When you install a new bandsaw blade, start by checking the positioning. Align the blade with the guides. Make sure it sits in the right groove. Next, tension the blade properly. If it’s too loose, it won’t cut well. If it’s too tight, it can break. Adjust until it feels just right. Test it on some scrap wood to ensure it cuts smoothly. Following these steps helps your bandsaw work better!

How do you properly tension a bandsaw blade?

To properly tension a bandsaw blade, make sure it is snug but not overly tight. Too much tension can cause damage. Check the manufacturer’s guide for specific settings. Adjust until you feel a bit of resistance when you press on the blade.

Tips for Proper Tensioning:

- Consult your bandsaw manual.

- Use a tension scale if available.

- Make small adjustments as needed.

Adjusting Bandsaw Settings After Blade Change

Importance of blade tracking adjustments. Checking and calibrating cutting speed settings.After changing the blade, it’s crucial to adjust the settings on your bandsaw. Proper blade tracking ensures that the blade runs smoothly and does not wear out quickly. Also, checking cutting speed helps you create clean cuts. Here are some tips:

- Make sure the blade tracks in the center of the wheels.

- Use the right speed for the material you cut.

- Regularly check tension for the best performance.

Why is adjusting bandsaw settings important?

Adjusting settings can prevent damage to the blade and machine. It improves accuracy in your cuts, making your projects look great.

Maintenance Tips to Extend Blade Life

Regular maintenance practices for bandsaw blades. How to properly clean and store blades.Taking care of your bandsaw blades can keep them sharp and ready for action. First, check them regularly for any signs of wear. A sharp blade cuts better and is safer to use. Cleaning your blades is easy; use a wire brush to remove dust and resin. Don’t forget to store them properly! Keep them in a dry place, away from moisture—rust is not a blade’s best friend. Replace blades with a dull edge to avoid frustration. Remember, a happy blade is a sharp blade!

| Maintenance Task | Frequency |

|---|---|

| Inspect blades for wear | Before each use |

| Clean blades | Weekly |

| Store blades | After each use |

Common Mistakes to Avoid

Frequent errors during blade changes and how to prevent them. Tips on troubleshooting postinstallation issues.| Common Mistakes | How to Avoid Them |

|---|---|

| Forgetting to unplug the bandsaw | Always unplug before changing the blade. Safety first! |

| Incorrect blade tension | Check tension with a gauge to avoid wobbling. Wobble equals trouble! |

| Not following manufacturer instructions | Read the manual! It’s like not using a map and getting lost. |

Changing bandsaw blades can be tricky, but little mistakes can make it tougher. One big no-no is forgetting to unplug the saw. You wouldn’t want a surprise on your fingers! Adjusting the blade tension correctly is crucial. If it feels loose, your cuts will look like a toddler drew them! Finally, don’t skip the manual. It’s there for a reason, like a treasure map for the workshop.

If a new blade makes funny noises or vibrates, it might be too loose or not aligned right. Keep an ear out for any weird sounds; they might just be the blade’s way of calling for help!

Conclusion

In summary, changing bandsaw blades is easy with the right tips. Always make sure the machine is off and unplugged for safety. Use proper tools to avoid injury. Check your blade tension often for smooth cuts. Now that you know these tips, practice changing the blade today. For more ideas, check guides or videos online to sharpen your skills!FAQs

What Are The Signs That Indicate It’S Time To Change The Blade On A Bandsaw?You know it’s time to change the blade on a bandsaw if the cuts are rough or uneven. If the blade makes strange noises, like squeaking or rattling, that’s a sign too. You might also notice if the blade gets really hot when you use it. If you see any rust or damage on the blade, it’s best to replace it. Changing the blade will help you make better cuts!

How Do I Properly Remove And Install A Bandsaw Blade?To remove a bandsaw blade, first turn off the machine and unplug it. Then, loosen the tension by turning the knob. Carefully take off the old blade from the wheels. To install a new blade, place it on the wheels, making sure it fits properly. Finally, tighten the tension and plug the machine back in. You’re ready to cut!

What Safety Precautions Should I Take When Changing A Bandsaw Blade?When changing a bandsaw blade, always unplug the machine first. Wear safety goggles to protect your eyes. Keep your fingers away from the blade and use tools to help. Make sure the area is clean and dry to avoid slipping. Finally, check that everything is tight and secure before you plug it back in.

How Can I Choose The Right Type Of Blade For My Specific Bandsaw Cutting Needs?To choose the right blade for your bandsaw, think about what you’ll cut. If you need to cut thick wood, pick a strong blade. For curves, choose a narrower blade to make turns easier. Check the teeth count, too; more teeth give smoother cuts. Always choose the blade that fits your saw!

What Maintenance Practices Can Help Extend The Life Of A Bandsaw Blade?To keep your bandsaw blade working well, you can follow some simple steps. First, always keep the blade clean. You can use a soft brush to remove sawdust. Next, check the blade regularly for any damage. Finally, make sure the blade is properly tensioned and aligned. Taking care of your blade will help it last longer!