Clean nail gun operation keeps your projects looking professional and your tools working like a charm. Follow this essential guide for simple, effective tips to ensure your nailer fires straight, prevents jams, and lasts for years. Master these techniques and enjoy smoother, safer DIY and woodworking sessions.

Hey there, fellow DIYers and woodworkers! Jack Shaffer, your friendly neighborhood Nailerguy, here. Ever fired up your nail gun, only to have it snag, jam, or shoot nails at an awkward angle? It’s frustrating, right? A clean nail gun isn’t just about looks; it’s about performance, safety, and making your projects shine. When your nailer is running smoothly, you save time, avoid costly repairs, and get that satisfying thud of a perfectly placed nail every single time. You might think a nail gun is just a tool, but the way you treat it makes a world of difference.

Don’t worry if you’ve had a few hiccups. Learning the ropes is part of the fun! In this guide, we’ll walk through the best tips for clean nail gun operation, step-by-step. We’ll cover everything from setting up correctly to routine maintenance that will keep your nailer happy and healthy. Get ready to boost your confidence and your project quality!

Table of Contents

Why Clean Nail Gun Operation Matters

Operating your nail gun cleanly goes way beyond just making it look good. It’s fundamental to ensuring your tool performs at its best and keeps you and your work safe. Think of it like keeping your car tuned up; a little regular attention prevents big, expensive problems down the road.

When you maintain a clean nail gun, you’re actively working to:

- Prevent Jams: Dust, debris, and old lubricant can build up inside the mechanism, leading to frustrating nail jams. A clean gun means nails feed smoothly.

- Ensure Proper Drive: A clean firing mechanism and piston ensure nails are driven consistently and accurately into your workpiece, giving your projects a professional finish.

- Extend Tool Life: Regular cleaning removes corrosive elements and wear-inducing grit, helping your nail gun last much longer.

- Boost Safety: A malfunctioning nail gun can be dangerous. Keeping it clean reduces the risk of unexpected firing or jam-related accidents.

- Improve Efficiency: A clean, well-lubricated tool works faster and requires less effort from you, making your work more enjoyable and productive.

Understanding Your Nail Gun: The Basics

Before we dive into the cleaning tips, let’s quickly touch on the parts of a nail gun that matter most for operation and maintenance. Knowing these will help you understand why certain cleaning steps are important.

- Magazine: This is where the nails are loaded. Keeping it free of debris ensures nails feed correctly.

- Driver Blade: This is the part that strikes the nail head and drives it into the wood. It needs to be clean and move freely.

- Piston/Cylinder: The piston moves rapidly within the cylinder to drive the blade. Lubrication and cleanliness here are crucial for smooth operation.

- O-rings and Seals: These keep air contained and prevent leaks. Damaged or dirty seals can lead to power loss.

- Air Inlet: Where you connect your air hose. Keeping this clean prevents contaminants from entering the tool.

Essential Pre-Operation Checks for a Clean Start

The best way to ensure clean operation is to start with checks before you even pull the trigger. This simple routine can prevent many common issues.

-

Inspect the Nail Gun: Give your nailer a quick visual once-over. Look for any obvious damage to the housing, the magazine, or the nose. Check that the safety tip is intact.

-

Check the Magazine: Ensure the magazine is clear of any old nails, wood fragments, or dust. If it’s dirty, gently wipe it out with a clean, dry cloth. If there are stubborn bits, you might need a small brush.

-

Verify Air Pressure: This is critical. Too much air pressure can damage the tool and drive nails too deep, while too little means weak drives. Consult your nail gun’s manual for the recommended PSI range. It’s usually between 70-120 PSI, depending on the type of nailer. Having a regulator on your air compressor is key for precise control. For guidance on air compressors, check out resources on energy efficiency standards for tools from the U.S. Department of Energy, which often includes information on compressor operation and selection.

-

Connect the Air Hose Properly: Make sure the air hose connection is secure and leak-free. A loose connection can lead to intermittent power and noise.

-

Load the Correct Nails: Always use nails recommended by the manufacturer for your specific nail gun. Using the wrong size or type can cause jams and damage.

Mastering Safe Nail Gun Handling

Safety is paramount. A clean nail gun is a safer nail gun, but proper handling is non-negotiable.

- Always Treat it Like It’s Loaded: Even if you just checked, assume the nail gun can fire at any moment.

- Never Point it at Anyone: This sounds obvious, but it’s worth repeating. Keep the muzzle pointed away from yourself and others.

- Engage the Safety Contact Tip: Most nail guns have a safety mechanism on the tip. Ensure it’s in contact with the workpiece before you pull the trigger. This prevents accidental firing.

- Use Safety Glasses: Always, always, always wear safety glasses or a face shield. Flying debris or ricocheting nails are serious hazards.

- Disconnect Air When Not in Use: If you’re moving to a new location, taking a break, or performing maintenance, disconnect the air supply.

- Keep Fingers Away from the Trigger and Tip: Don’t rest your finger on the trigger unless you intend to fire. Keep your hands and other body parts away from the firing line.

Step-by-Step Guide to Clean Nail Gun Operation

Now let’s get down to the practical steps that will keep your nail gun firing cleanly and consistently. These steps are designed for typical pneumatic (air-powered) nail guns, which are the most common for DIYers.

Step 1: Prepare Your Workspace and Tool

Before you start firing, make sure your environment is conducive to clean work. Clear away sawdust, debris, and anything that could be accidentally kicked up or inhaled.

- Clear your work area of loose debris.

- Ensure good ventilation, especially if you’re using lubricants.

- Have your safety gear ready (glasses, gloves).

- Disengage the air supply to the nail gun.

Step 2: Load Nails Correctly

The magazine is a critical component. Proper loading prevents misfeeds and jams.

- Slide open the magazine follower.

- Place a strip of the correct nails into the magazine, ensuring they sit flat.

- Slide the follower back gently until it holds the nails securely. Don’t force it.

- Ensure the nail strip isn’t bent or damaged.

Step 3: Connect Air and Set Pressure

This is where your air compressor comes in. Setting the right pressure is key.

- Connect your air hose to the nail gun’s air inlet.

- Turn on your air compressor and let it build pressure.

- Adjust the regulator on your compressor to the recommended PSI for your nail gun. A good starting point for many framing and finishing nailers is around 90 PSI. Consult your manual for specifics. You can find resources on OSHA regulations for pneumatic tools which highlight safety aspects of air pressure.

- Listen for leaks. A small hiss might be normal, but a loud, continuous leak needs attention.

Step 4: Test Fire (Safely!)

Before you start on your project, it’s wise to do a test fire to ensure everything is working correctly.

- Find a scrap piece of wood.

- Hold the nail gun firmly against the scrap wood, ensuring the safety contact tip is pressed against the surface.

- Pull the trigger.

- Listen to the sound. It should be a crisp “pop” or “thud.”

- Check the nail. It should be driven flush or to the desired depth.

- If the nail isn’t driven correctly or the tool sounds weak, check air pressure, nail loading, and look for obvious issues.

Step 5: Maintain Consistent Firing Technique

Once you start your project, consistency is key for both quality and clean operation.

- Firm Contact: Always press the nose of the nailer firmly against the wood. This engages the safety mechanism and ensures a solid drive.

- Smooth Trigger Pull: Pull the trigger smoothly. Jerky movements can cause inconsistent nail placement.

- Nail Placement: Aim for the desired location. Avoid driving nails too close to the edge of boards, which can cause splitting.

- Clear Jams Promptly: If a jam occurs, immediately disconnect the air supply before attempting to clear it.

Troubleshooting Common Nail Gun Issues

Even with the best care, you might encounter a hiccup. Here’s how to tackle common problems for clean operation.

Nail Jamming

Cause: Often due to incorrect nail size, bent nails, debris in the magazine, or worn internal parts.

Fix:

- Disconnect air.

- Open the magazine.

- Remove any obstructing nails.

- Inspect the nail strip for bends.

- Check the driver blade for obstructions.

- If jams are frequent, the internal mechanism might need professional service.

Nails Not Driving Fully

Cause: Low air pressure, faulty O-rings, or a dirty piston/cylinder.

Fix:

- Check and increase air pressure if necessary.

- Ensure the air hose is adequate for the tool’s requirements.

- Inspect O-rings for wear or damage.

- Clean the internal parts (see maintenance section).

Nails Firing Sideways or Angled

Cause: The firing mechanism might be obstructed, or the driver blade is bent. Sometimes, insufficient workspace for the safety contact tip to engage properly can contribute.

Fix:

- Disconnect air.

- Carefully inspect the driver blade for damage.

- Ensure the nose of the gun is clean and not obstructed, allowing proper contact with the wood.

- If you suspect a bent driver blade, it’s time for professional repair or replacement.

Air Leaks

Cause: Loose connections, damaged O-rings, or cracked housing.

Fix:

- Check all hose connections.

- Inspect O-rings, especially around the air inlet and cylinder head. Replace if worn or cracked.

- A faint hiss might be normal, but loud leaks indicate a problem that needs fixing.

Routine Maintenance for Optimal Performance

Consistent, simple maintenance is the secret to long-term clean nail gun operation. It doesn’t take much time and pays off big.

1. Daily: Quick Clean-Up

After each use, take two minutes to clean your nail gun.

- Disconnect the air supply.

- Wipe down the exterior with a clean, dry cloth.

- Clear out any dust or debris from the magazine and around the nosepiece.

2. Weekly: Lubrication (If Required)

Many pneumatic nail guns require occasional lubrication. Always check your manual first. Some modern tools have oil-free motors. If yours requires oil:

- Disconnect the air supply.

- Locate the air inlet.

- Add 1-2 drops of specialized pneumatic tool oil (never WD-40 or general lubricants, as they can attract dust and gunk up the tools).

- Reconnect the air and fire the tool a few times into scrap wood to distribute the oil.

This simple step ensures the internal moving parts, like the piston and driver blade, move smoothly and are protected against rust.

3. Monthly/As Needed: Deeper Cleaning and Inspection

A more thorough clean can prevent issues before they start.

- Disconnect the air.

- Remove the magazine if possible and clean it thoroughly.

- Use a soft brush and a clean cloth to clean the nosepiece and the area around the driver blade.

- For a deeper clean of the internal mechanism, you may need to remove the cylinder head. Only attempt this if you are comfortable and consult your manual. Many DIYers find it easier to take it to a professional for this level of service.

- Inspect the driver blade for any nicks, bends, or excessive wear.

- Check all O-rings and seals for cracks or degradation.

What NOT to Do

Just as important as what you should do is what you shouldn’t do to keep your nailer in top shape.

- Don’t use WD-40 or household oils: These attract dust and can gum up the internal mechanisms. Use only specialized pneumatic tool oil if your tool requires it.

- Don’t force nails: Ensure you’re using the correct nail size and type for your gun.

- Don’t use excessive force: Let the tool do the work. Proper air pressure is key, not brute strength.

- Don’t ignore jams or malfunctions: Address issues promptly.

- Don’t immerse it in water: Most nail guns are not designed to be submerged.

Tool Comparisons: Nailer Types and Their Operation Quirks

Different types of nail guns have slightly different operational needs and maintenance considerations. Understanding these can help you maintain them better.

| Nail Gun Type | Power Source | Typical Use | Operation Notes |

|---|---|---|---|

| Framing Nailer | Pneumatic | Rough framing, joists, decks | High power, requires significant air volume. Keep magazine clear of sawdust. |

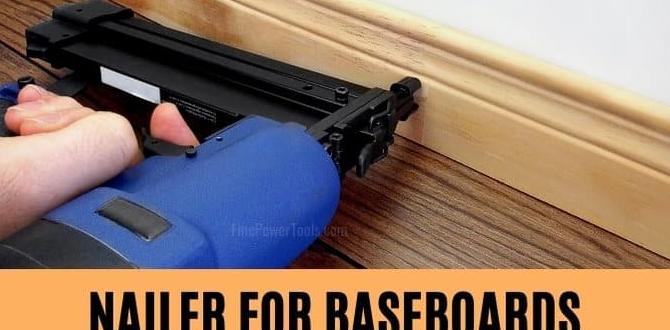

| Finish Nailer | Pneumatic, Battery, Gas cartridge | Trim work, molding, baseboards | Precision driving. Oil-free battery/gas models require different maintenance. |

| Brad Nailer | Pneumatic, Battery | Small trim, delicate molding, craft projects | Lighter duty, sensitive to dust. Lubrication is often key for pneumatic models. |

| Pin Nailer | Pneumatic, Battery | Attaching very delicate trim, small projects, no holding power | Extremely fine point. Requires meticulous cleaning to avoid jamming the very small driver. |

| Roofing Nailer | Pneumatic | Shingles, roofing | Designed for harsh outdoor conditions; requires robust cleaning of debris and grit. |

While the core principles of clean operation apply to all, battery-powered nailers may have fewer lubrication needs but require battery maintenance. Gas cartridge nailers need their fuel cells replaced and occasional cleaning of the combustion chamber. Always defer to the manufacturer’s manual for specific care instructions.

When to Seek Professional Help

While most maintenance tasks are simple enough for a DIYer, some issues are best left to the pros. If you experience:

- Persistent, unfixable jams.

- A bent or damaged driver blade.

- Significant air leaks that aren’t from loose connections.

- A complete loss of power that isn’t related to air supply.

- The tool making strange noises (grinding, rattling).

These could indicate internal wear or damage that requires specialized knowledge and tools to repair safely and effectively. Check with your tool manufacturer for authorized repair centers.

Frequently Asked Questions (FAQ)

Q1: How often should I lubricate my pneumatic nail gun?

A1: If your nail