Looking for the best roofing nail gun that can handle asphalt shingles and even metal roofing? This guide will help you choose the right one for your project, ensuring a secure and efficient roof installation without the fuss. Let’s get nailing!

Hey there, fellow DIYer! Jack Shaffer, Nailerguy, here. Tackling a roof project can seem like a big job, right? Especially when it comes to securing those shingles or metal sheets. The wrong tool can lead to missed nails, sore arms, and a roof that just doesn’t feel quite right. But don’t worry, choosing the right roofing nailer is easier than you think! With the right information, you’ll be confidently selecting a tool that makes your roofing job faster, safer, and much more enjoyable. We’ll walk through everything you need to know.

Table of Contents

Why a Roofing Nail Gun is a Game-Changer

Before we dive into specific models, let’s chat about why investing in a roofing nail gun is such a smart move for any homeowner or DIY enthusiast. Imagine trying to hammer in thousands of roofing nails by hand. It’s not just exhausting; it’s also time-consuming and increases the risk of errors and injuries. A good roofing nailer automates this process, driving nails precisely and quickly with every trigger pull.

This means less physical strain, a significantly reduced project timeline, and a more professional, secure finish for your roof. For everything from a small shed repair to a full roof replacement on your home, a roofing nail gun will be your best friend. It’s designed for the specific task of roofing, so it handles the unique requirements of this job with ease.

Types of Roofing Nail Guns

When you start looking, you’ll notice there are a few main types of roofing nail guns. Each has its own advantages, making it better suited for different needs and preferences. Understanding these types is the first crucial step in finding your perfect match.

Pneumatic (Air-Powered) Roofing Nail Guns

These are the workhorses of the roofing world. Pneumatic nailers are powered by compressed air from an air compressor. They are known for their power, speed, and durability.

- Pros:

- Incredible power: Easily drives nails into tough materials.

- High speed: Ideal for large projects where speed is essential.

- Lighter weight (tool itself): The compressor does the heavy lifting.

- Durability: Generally built to last for many years of heavy use.

- Cons:

- Requires an air compressor: An additional piece of equipment to buy and maintain.

- Hose management: You need to manage an air hose, which can be a minor hassle on the roof.

- Noise: Can be quite loud due to the air expulsion.

Cordless (Battery-Powered) Roofing Nail Guns

Cordless nailers have become increasingly popular thanks to advancements in battery technology. They offer portability and convenience without the need for a compressor or hoses.

- Pros:

- Ultimate portability: No hoses or compressors means freedom of movement.

- Easy setup: Grab it and go!

- Clean operation: No air lines to trip over.

- Cons:

- Power variation: Some models might not be as powerful as pneumatic ones for very dense materials.

- Battery life: You need to ensure batteries are charged, and might need spares for long days.

- Tool weight: The battery adds weight to the tool itself.

- Cost: Often have a higher initial purchase price.

Electric (Corded) Roofing Nail Guns

While less common for roofing specifically, some electric nail guns exist. They plug directly into a power outlet.

- Pros:

- No need for compressor or batteries: Constant power supply.

- Typically more affordable initial cost.

- Cons:

- Limited mobility: You are tethered by an electrical cord, which is a significant drawback on a roof.

- Less power: Generally less powerful than pneumatic or higher-end cordless models.

- Not ideal for large-scale roofing projects due to cord management.

For most roofing jobs, especially asphalt and metal shingles, pneumatic or high-quality cordless models are the way to go. They offer the power and speed necessary for efficient and secure installations.

Key Features to Look For in a Roofing Nail Gun

When you’re browsing for your next roofing nail gun, keep these important features in mind. They’ll ensure you get a tool that’s safe, effective, and comfortable to use.

Adjustable Depth Control

This is crucial! It allows you to set how deep each nail is driven into the roofing material. Too shallow, and the nail won’t hold well. Too deep, and you risk driving the nail head flush or even below the shingle surface, which can damage the shingle and create a leak point. Look for a tool with an easy-to-use, precise depth adjustment mechanism, often a dial or lever near the nose of the gun.

Nail Capacity and Loading System

Roofing nail guns typically use collated nails held together by adhesive or paper. You’ll want a gun that can hold a sufficient number of nails for extended work without constant reloading. A quick and easy loading system is also a big plus, especially when you’re on a sloped roof!

Nail Type and Size Compatibility

Most roofing nailers are designed for specific nail types and sizes. Ensure the gun you choose is compatible with the type of nails required for your roofing material. For asphalt shingles, you’ll typically use 1-1/4″ to 1-1/2″ galvanized roofing nails. For metal roofing, the fasteners might be different, and you’ll need to confirm tool compatibility. Always check the manufacturer’s specifications regarding nail length and diameter.

Lightweight Design and Ergonomics

You’ll be holding this tool for extended periods, often overhead or at awkward angles. A lightweight tool with a comfortable grip and good balance will significantly reduce fatigue and improve control. Some guns also feature rubber grips and minimal vibration to enhance comfort.

Sequential vs. Contact Actuation

This refers to how the nail gun fires.

- Sequential (Restricted) Fire: You must sequentially press the safety contact nose against the surface and then pull the trigger to fire a nail. This offers the highest safety and precision, preventing accidental firing.

- Contact (Bump) Fire: You hold the trigger down and bump the nose against the surface to fire nails. This is much faster for laying down a lot of nails quickly but requires more caution.

For roofing, sequential fire is generally recommended for safety, especially when working on uneven surfaces or at heights. However, many professional roofers prefer contact fire for its speed on large jobs, after extensive training and practice.

Durability and Build Quality

Roofing is tough work, and your tool should be able to handle it. Look for tools from reputable brands known for their durability. Features like a magnesium or aluminum housing, hardened steel internal parts, and robust seals (for pneumatic models) indicate good build quality that will withstand jobsite conditions.

Safety Features

Beyond actuation type, look for features like a well-designed safety contact nose that prevents the gun from firing unless pressed against a surface. Some even have adjustable exhaust ports to keep dust and debris away from your face.

Top Roofing Nail Guns on the Market

Now that you know what to look for, let’s explore some of the best roofing nail guns available. These are popular choices among professionals and DIYers alike, offering a great balance of performance, durability, and value. We’ll focus on models great for asphalt shingles and those versatile enough for metal applications.

1. Hitachi/Hikoki NV45AE(S) Coil Roofing Nailer

This is a staple in the professional roofing industry for a reason. It’s a pneumatic powerhouse known for its reliability and performance on asphalt shingles.

- Type: Pneumatic

- Nail Range: 3/4″ to 1-3/4″

- Capacity: 120 nails

- Key Features: Lightweight aluminum housing, tool-less depth adjustment, side-loading magazine for quick reloads, dry-fire lockout.

- Best For: Asphalt shingles, felt paper, insulation board.

2. Senco RoofPro 455XP Coil Roofing Nailer

Senco is another top-tier brand in the fastener tool world. The RoofPro 455XP is a direct competitor to the Hitachi, offering robust construction and excellent driving power.

- Type: Pneumatic

- Nail Range: 3/4″ to 1-3/4″

- Capacity: 120 nails

- Key Features: Aggressive sawtooth grip for stability, tool-less depth of drive, comfortable ergonomic grip, rain hood to protect the mechanism.

- Best For: Asphalt shingles and other standard roofing applications.

3. DeWalt DCN482B Cordless 20V MAX XR Roofing Nailer

For those who want freedom from air hoses, DeWalt offers a compelling cordless option. It’s powered by their 20V MAX XR battery system, offering excellent convenience.

- Type: Cordless (Battery-Powered)

- Nail Range: 1″ to 1.75″

- Capacity: 120 nails

- Key Features: Brushless motor for efficiency, tool-free depth adjustment, integrated belt hook, LED light to illuminate the work area, sequential and contact actuation modes.

- Best For: Asphalt shingles. Compatibility with some metal roofing applications should be verified.

4. Milwaukee M18 FUEL Cordless Roofing Nailer (2746-20)

Milwaukee is making serious waves in the cordless tool market, and their roofing nailer is a tough contender. It boasts impressive power and good battery life.

- Type: Cordless (Battery-Powered)

- Nail Range: 1″ to 1-3/4″

- Capacity: 110 nails

- Key Features: POWERSTATE™ brushless motor, REDLINK PLUS™ intelligence for optimal performance and overload protection, nitrogen-powered system for consistent drives, tool-free depth adjustment, integrated rafter hook.

- Best For: Asphalt shingles. Again, check for specific metal roofing needs.

5. Metabo HPT (Hitachi) NT45A5 Coil Roofing Nailer

Metabo HPT is the new name for Hitachi’s power tool division, carrying over the same quality. This pneumatic model is a reliable choice for serious roofing work.

- Type: Pneumatic

- Nail Range: 3/4″ to 1-3/4″

- Capacity: 120 nails

- Key Features: Lightweight magnesium housing, side-loading magazine for easy reloads, adjustable firing depth, comfortable rubber grip.

- Best For: Asphalt shingles and general roofing applications.

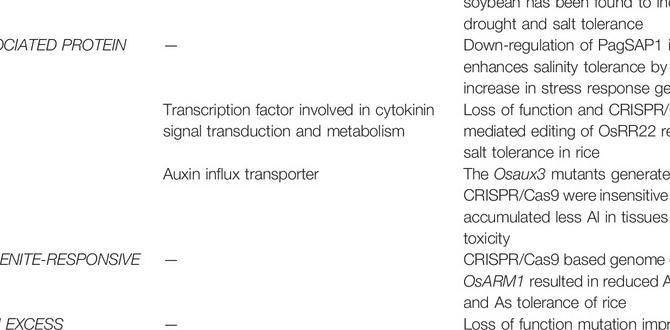

Roofing Nailer Comparison Table

Here’s a quick look at some of the top contenders side-by-side:

| Model | Type | Max Nail Length | Nail Capacity | Power Source | Pros | Cons |

|---|---|---|---|---|---|---|

| Hitachi/Hikoki NV45AE(S) | Pneumatic | 1-3/4″ | 120 | Air Compressor | Powerful, durable, lightweight tool, reliable | Requires compressor and hose |

| Senco RoofPro 455XP | Pneumatic | 1-3/4″ | 120 | Air Compressor | Robust, excellent power, good grip | Requires compressor and hose |

| DeWalt DCN482B | Cordless | 1.75″ | 120 | 20V MAX XR Battery | Cordless freedom, good power for cordless, tool-free adjustment | Battery life and recharge time, higher initial cost |

| Milwaukee M18 FUEL 2746-20 | Cordless | 1-3/4″ | 110 | M18 Battery | Powerful cordless, consistent drives, advanced motor | Battery life and recharge time, higher initial cost |

| Metabo HPT NT45A5 | Pneumatic | 1-3/4″ | 120 | Air Compressor | Lightweight, durable, easy loading | Requires compressor and hose |

Nail Selection for Roofing

Choosing the right nails is just as important as choosing the right nail gun. Using the wrong nails can lead to poor performance, corrosion, and potential roof leaks.

For Asphalt Shingles:

- Type: Galvanized roofing nails are essential. The galvanization prevents rust, which is critical for outdoor exposure.

- Size: Typically range from 1-1/4 inch to 1-1/2 inch in length. The exact length depends on the shingle thickness and manufacturer recommendations. You want the nail to penetrate the shingle and the underlayment, and embed into theRoof decking by at least 1/2 inch.

- Head: A wide, flat head is standard for roofing nails, providing a large surface area to hold down the shingle effectively.

For Metal Roofing:

Metal roofing often uses specialized screws or nails. For screw-driven applications, self-tapping screws with neoprene washers are common. If using nails for metal roofing (less common for primary fastening but possible for some attachments), you’ll typically use ring-shank galvanized nails. Always consult the metal roofing manufacturer’s installation guide for the correct fasteners. Your roofing nailer must be capable of firing the specified nail size and type. Some roofing nailers can also be used for attaching metal panels, but verify the manufacturer’s recommendations for compatibility and nail head type.

A quick tip: Always use siding nails for siding and roofing nails for roofing. They are designed for different purposes and materials!

Safety First: Essential Precautions

Working on a roof is inherently risky. Safety should always be your absolute top priority. A roofing nail gun, while efficient, is a powerful tool that demands respect. Always follow these safety guidelines:

- Wear Proper Safety Gear:

- Safety Glasses: Non-negotiable. Always wear ANSI Z87.1-compliant safety glasses or goggles to protect your eyes from flying debris or nail fragments.

- Work Gloves: Protect your hands from splinters and provide a better grip.

- Sturdy Footwear: Shoes with good traction are crucial for maintaining balance on a sloped surface.

- Hard Hat: Protects against falling objects or accidental bumps.

- Hearing Protection: Especially for pneumatic nailers, earplugs or earmuffs are recommended.

- Read the Manual: Before using any new tool, thoroughly read and understand the manufacturer’s operating manual.

- Inspect Your Tool: Check the nail gun for any damage before each use, including the air hose (if pneumatic) and all connection points.

- Never Point the Gun at Anyone: Treat the nail gun like a firearm. Never point it at yourself or others, even if you think it’s unloaded and disengaged.

- Engage Safety Nose/Trigger: Always ensure the safety contact nose is depressed before you pull the trigger. If using contact fire for speed, be extraordinarily careful about where you aim and point the tool.

- Work on Stable Surfaces: Ensure you have a secure footing. Use scaffolding or safety harnesses when working at significant heights, as recommended by regulations like those from the Occupational Safety and Health Administration (OSHA).

- Power Management: For pneumatic nailers, ensure the air pressure is set correctly and the hose is not kinked or damaged. For cordless, make sure batteries are secure and charged.

- Keep Fingers Away: Never place your finger on the trigger unless you intend to fire a nail.