Quick Summary: The best nailer for hardwood floors is a specialized flooring nailer, either pneumatic or electric, designed to drive L-shaped staples or nails at a slight angle. This method securely fastens your hardwood planks without damaging the surface, ensuring a professional and durable finish.

Laying hardwood floors can be a dream project for any homeowner looking to add warmth and value to their space. But when it comes to securing those beautiful planks, things can feel a little daunting. You’ve probably heard that nailing is the way to go, but what’s the right tool for the job? Using the wrong nailer can lead to scuffed floors, bent nails, or worse, weak connections that give way over time. Don’t worry, though! With the right information, you can confidently choose the best nailer for hardwood floors and get that stunning result you’re after. We’ll walk you through everything you need to know.

Table of Contents

Choosing the Right Nailer for Your Hardwood Flooring Project

As Jack Shaffer, your trusted guide from Nailerguy, I understand the excitement and the little bits of nervousness that come with tackling a big DIY project like hardwood flooring. It’s a beautiful finish, and you want it done perfectly. The key to that perfect finish often lies in the tools you use, particularly your nailer. For hardwood floors, we’re not just talking about any old nail gun. We need something specific to the task, something that respects the wood while holding it firmly in place.

There are a few main types of nailers that people consider for flooring. However, when it comes to hardwood, one category truly stands out as the proven solution. Let’s break down what makes it so special and why it’s your best bet for a professional-looking outcome.

The Star of the Show: The Flooring Nailer

When we talk about the “best nailer for hardwood floors,” almost universally, we’re referring to a dedicated flooring nailer. These tools are designed from the ground up specifically for installing the tongue-and-groove system of hardwood planks.

What makes them unique? They don’t just drive nails straight down. Instead, they use a specialized magazine and striking mechanism to drive L-shaped staples or L-shaped nails at a precise angle. This angle is crucial. It allows the fastener to go through the tongue of the hardwood plank and securely anchor into the subfloor. This “toe-nailing” action provides a much stronger grip than a straight nail could, preventing the planks from lifting or shifting over time. Plus, because the fastener is driven into the tongue, it’s largely hidden from view once the next board is laid, leading to a clean, professional look. For more on subfloor preparation, the U.S. Department of Housing and Urban Development (HUD) offers valuable guidance on building codes and best practices which includes subfloor considerations.

Types of Flooring Nailers

Flooring nailers come in a few variations, primarily based on their power source. Each has its pros and cons, and the best choice for you will depend on your project size, budget, and personal preference.

1. Pneumatic Flooring Nailers

These are the workhorses of the professional flooring installation world. They connect to an air compressor, which provides the power to drive the fasteners. Pneumatic nailers are known for their speed, power, and reliability.

- Pros:

- Extremely powerful, easily driving fasteners into dense hardwood.

- Fast firing rate, making installation quicker.

- Lighter weight compared to some electric models.

- Generally more durable and longer-lasting.

- No power cord to manage, offering better mobility.

- Cons:

- Requires an air compressor and an air hose, adding extra equipment and setup time.

- Compressors can be noisy.

- Initial cost for a compressor can be significant.

2. Electric (or Corded) Flooring Nailers

These nailers plug directly into a standard electrical outlet. They use a motor and sometimes a spring-loaded mechanism to drive the fasteners.

- Pros:

- No need for an air compressor or hose, simplifying setup.

- Quieter operation than pneumatic systems.

- Ideal for smaller projects or for DIYers without existing compressor equipment.

- Cons:

- May struggle with extremely dense hardwoods if not powerful enough.

- Can be heavier than pneumatic counterparts.

- The power cord can sometimes get in the way.

- Generally slower firing rate than pneumatic models.

3. Manual Flooring Nailers (Bombay Nailers/Cleats)

These are the most basic and affordable option. They require you to manually strike a plunger with a mallet to drive a cleat (a type of fastener) into the wood. They are often used for finishing work in corners, around vents, or for very small areas where a powered nailer is impractical.

- Pros:

- Very inexpensive.

- No power source needed.

- Excellent for tight spaces and detailed work.

- Cons:

- Very slow and labor-intensive for large areas.

- Requires significant physical effort.

- Not suitable for installing entire floors.

For installing entire hardwood floors, a pneumatic or electric flooring nailer is your best bet. The manual ones are more of a supplemental tool.

What About Other Nailer Types? (And Why They Aren’t Ideal)

You might be wondering about other common nail guns like framing nailers, finishing nailers, or brad nailers. While these are fantastic tools for many woodworking and construction tasks, they are generally not suitable for installing hardwood flooring.

- Framing Nailers: These are built for heavy-duty construction and drive large nails. They would likely split hardwood planks and damage the subfloor.

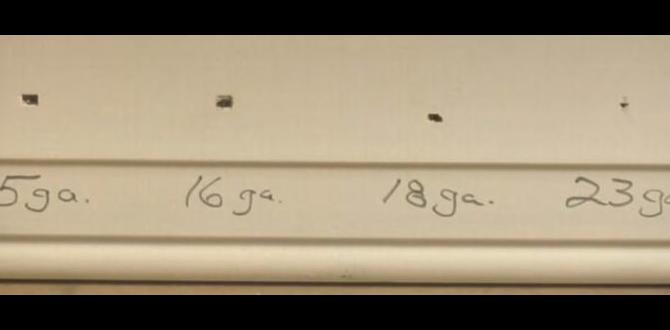

- Finishing Nailers (15-gauge or 16-gauge): These drive thinner, straight nails. While they might work for some very select, thin engineered hardwoods with careful placement, they don’t offer the secure angled grip needed for solid hardwood. They also leave visible nail heads which would need filling.

- Brad Nailers (18-gauge): These are even smaller and finer than finishing nailers and are used for delicate trim work. They simply don’t have the power or the design to hold hardwood flooring in place.

The specialized design of a flooring nailer, with its angled fastener drive and often a base plate to protect the floor surface, makes it the clear winner for this specific job. It’s built to handle the forces involved and to give you that professional, seamless finish.

Key Features to Look For in a Flooring Nailer

When you’re ready to purchase or rent the best nailer for your hardwood floors, keep an eye out for these important features:

1. Fastener Type: Staples vs. Nails

Flooring nailers typically use one of two types of fasteners:

- L-Shaped Staples (Cleats): These are the most common. They have a short shank with a wider, barbed head that grips the tongue of the wood. They offer excellent holding power. Look for brands that offer a good variety of staple lengths (e.g., 1-1/2 inch, 2 inch) to match your flooring thickness.

- L-Shaped Nails: Some flooring nailers also drive L-shaped nails, which function similarly to staples. The choice between staples and nails often comes down to manufacturer preference or specific flooring requirements.

Always check the compatibility of the nailer with the fasteners you plan to use. Using the wrong type can cause jams or damage the tool.

2. Power Source and Performance

As discussed, this will likely be pneumatic or electric. For pneumatic, ensure your compressor can provide adequate PSI (pounds per square inch) and CFM (cubic feet per minute) for the nailer to operate efficiently. For electric, verify the wattage or amperage to ensure it has enough power for your hardwood species.

3. Magazine Angle and Loading Mechanism

The angle of the magazine is what allows for the precise toe-nailing. A well-designed magazine will also be easy to load with fasteners, minimizing downtime.

4. Built-in Base Plate or Mallet Actuation

Professional flooring nailers often have a built-in base plate that rests on the flooring being installed or on the tongue of the board. This helps guide the tool and protects the floor surface from accidental impact. Manual-style flooring nailers (sometimes called “Bombay” nailers) are strike-activated with a rubber mallet. These are typically used for the final boards or in tight spots.

5. Ergonomics and Weight

You’ll be holding and operating this tool for extended periods. A comfortable grip, balanced weight, and ease of use can make a big difference in your fatigue levels.

6. Durability and Brand Reputation

For a project like hardwood flooring, investing in a quality tool from a reputable brand is wise. Look for brands known for their reliability in the construction and tool industry. Reading reviews from other DIYers or professionals can offer valuable insights.

Top Picks: Best Nailer for Hardwood Floors (Examples)

While specific models change, here are some examples of highly regarded flooring nailers that consistently perform well. These represent the types of tools you should be looking for.

Pneumatic Flooring Nailers

Example: Bostitch MFN-125 Flooring Nailer

This is a popular choice among professionals and serious DIYers. It’s known for its robust construction and ability to handle various hardwood species. It uses L-shaped staples.

Example: DeWalt DWFP12611 Flooring Nailer

DeWalt is another well-respected brand. This pneumatic nailer is a solid performer, offering good power and a comfortable ergonomic design. It also uses L-shaped staples.

Electric Flooring Nailers

Example: Freeman PFL618BR Pneumatic 3-in-1 Flooring Nailer (Considered as a Hybrid Option)

While called pneumatic, some combine functionality. For truly electric, look for models like…

Example: Wen 18-Gauge Pneumatic Brad Nailer (Note: This is NOT a flooring nailer for hardwood. This is an example of what NOT to use. It’s important to distinguish tools.)

To be clear, when looking for an electric flooring nailer specifically for hardwood, you’d be looking for models that are explicitly marketed as such, often powered by a more substantial motor than a typical brad nailer. These are less common than their pneumatic counterparts for the “best nailer for hardwood floors” title. Often, if you want electric convenience for flooring, you might look at compact, standalone electric nailers designed for laminate or engineered wood, but for solid hardwood, pneumatic remains the most prevalent and often most effective choice.

Important Note on Electric Flooring Nailers for Hardwood: True electric flooring nailers that can reliably drive fasteners into hardwood at the correct angle are less common than pneumatic options and often come with a higher price tag due to the powerful motor required. Many “electric” options you might find are better suited for thinner engineered wood or laminate flooring. For serious hardwood installation, a pneumatic system is generally recommended for its power and reliability. If you are set on electric, ensure the model specifically states it is designed for solid hardwood and has sufficient power.

Manual Floor Nailers (For Smaller Jobs/Finishing)

Example: PortaSoleil T-50 Manual Flooring Cleat Nailer

This small, manual tool is excellent for those tricky final rows or small closets where manhandling a larger nailer is difficult. You use a rubber mallet to strike the plunger.

When researching specific models, always check reviews, user forums, and manufacturer specifications to ensure it meets the demands of your particular hardwood flooring project. Websites like ToolGuyd often provide in-depth reviews and comparisons of various power tools.

Step-by-Step: How to Use a Flooring Nailer

Using a flooring nailer correctly is key to a successful installation. Here’s a simplified guide:

Step 1: Prepare Your Subfloor

Ensure your subfloor is clean, dry, and level. Remove any old flooring, nails, or debris. For a solid installation, especially with hardwood, a structurally sound plywood or OSB subfloor is essential. Check for excessive moisture, which can cause wood to warp. The National Wood Flooring Association (NWFA) provides comprehensive guidelines on subfloor preparation suitable for installing hardwood.

Step 2: Acclimate Your Flooring

Allow your hardwood planks to acclimate to the humidity and temperature of your home for several days (typically 3-7 days) before installation. This prevents excessive expansion or contraction after they are installed.

Step 3: Lay Your First Row

The first row of flooring needs to be installed differently, as there are no surrounding boards to nail into. It’s often glued or face-nailed (using nails driven through the surface of the plank, which will be covered by quarter-round molding or baseboards). Start with the grooved side facing the wall. Ensure this row is perfectly straight, as it will dictate the alignment of the rest of the floor.

Step 4: Position the Flooring Nailer

For subsequent rows, place the base of the flooring nailer against the tongue of the plank you are installing. The nose of the nailer should sit flush on the tongue, and the magazine should be angled correctly to drive the fastener into the subfloor at an approximate 30-37 degree angle. Most flooring nailers are designed to accept a specific type of cleat or staple, which will automatically feed into the correct position.

Step 5: Fire the Nailer

If using a pneumatic nailer, ensure your compressor is connected and set to the correct pressure (usually listed in the nailer’s manual or on the tool itself, often around 70-90 PSI). Press down firmly on the nailer to ensure it’s seated properly. Then, depress the trigger or actuating lever to drive the fastener. Some models may require you to strike a plunger with a mallet for each nail.

You’ll typically want to place fasteners every 6-8 inches along the length of the board and a couple of fasteners near the end of each board where it meets another board.

Step 6: Advance the Next Plank

Slide the groove of the next plank onto the tongue of the previously installed plank. Ensure a snug fit. You may need to use a tapping block and hammer gently to close any small gaps, but be careful not to damage the edges of the boards.

Step 7: Continue Laying Rows

Repeat steps 4-6 for each subsequent row. You will work your way across the room. For the last row, you might need to cut the tongue off the planks and secure them with face-nailing or glue, similar to the first row.

Step 8: Clean Up

Once the floor is installed, sweep up any sawdust or debris. If you used pneumatic tools, disconnect the air hose. If you used an electric tool, unplug it. Store your nailer and accessories properly.

Always refer to the specific instruction manual for your flooring nailer model, as operation can vary slightly between brands and models. Safety first – wear safety glasses at all times!

When to Rent vs. Buy

Deciding whether to buy a flooring nailer or rent one can be a key decision for your budget and project.

| Consider Renting if: | Consider Buying if: |

|---|---|

| You are only installing hardwood floors once or very rarely. | You plan to tackle multiple flooring projects in the future. |

| Budget is a primary concern for a single project. | You enjoy DIY projects and want to build your tool collection. |

| You don’t want to store a specialized tool long-term. | You have a large area to cover, and the cost of multiple rentals adds up. |

| You want to try a high-end model before committing to a purchase. | You value having the specific tool you need on hand, ready to go. |

Renting is often more economical for a one-off project. Rental shops usually carry good quality pneumatic flooring nailers and the necessary staples. However, if you see yourself doing more DIY home improvements down the line, purchasing your own flooring nailer