Picture this: you walk into a workshop, and the hum of a powerful motor fills the air. That’s the sound of creativity in action. A good bandsaw motor can be the heart of your workspace. Have you ever wondered what makes one motor better than another?

Whether you’re a woodworking enthusiast or a professional, choosing the best bandsaw motor is key. It helps you make clean cuts and tackle tough materials. But how do you know what to look for?

In this article, we’ll explore the top bandsaw motors. We’ll share tips to help you find the right fit for your needs. Get ready to unlock the secrets of bandsaw motors, and watch your projects come to life!

Table of Contents

Discover The Best Bandsaw Motor For Superior Performance

Choosing the best bandsaw motor can greatly enhance your woodworking projects. A powerful motor ensures smooth cutting, making tasks easier and faster. Did you know that the right motor can extend the life of your bandsaw? Look for motors with ample horsepower for tougher materials. Accessories and features, such as variable speeds, also play a crucial role in your bandsaw’s performance. Investing in a top-notch motor can turn your craft into a masterpiece!

Understanding Bandsaw Motors

Explanation of bandsaw motor types (AC, DC, and variable speed). Importance of motor power and RPM in bandsaw performance.

Bandsaw motors come in different types: AC, DC, and variable speed. AC motors are reliable and great for steady tasks. DC motors offer more control and change speeds easily. Variable speed motors let you adjust speeds for various cuts. The power of a motor and its RPM (revolutions per minute) is crucial. Higher power boosts performance. Fast RPM means cleaner cuts. Just like a bike, faster speeds get you to your destination quicker!

What is the best bandsaw motor type?

The best bandsaw motor type depends on your needs. For basic cutting, AC might be enough. If you need flexibility, consider variable speed. For precision, DC motors excel.

- AC Motors: Good for steady work.

- DC Motors: Great for speed changes.

- Variable Speed: Best for different tasks.

Key Features to Consider in a Bandsaw Motor

Power rating and its impact on cutting capacity. Motor efficiency and energy consumption considerations.

Choosing the right motor for your bandsaw is important. Consider the power rating first. It affects how well your saw cuts. A higher power rating means better cutting capacity. Next, think about motor efficiency. An efficient motor uses less energy. This helps save on electricity costs. Look for a motor that balances power and efficiency.

What should I know about bandsaw motors?

Understanding bandsaw motors is key for great performance. The power rating affects how deep and fast you can cut. Higher ratings lead to better cuts. An efficient motor is important too, saving energy and reducing bills.

- Power Rating: Impacts cutting speed and depth.

- Motor Efficiency: Saves energy and reduces costs.

Installation Tips for Bandsaw Motors

Stepbystep guide on how to install a bandsaw motor. Common pitfalls to avoid during installation.

Installing a bandsaw motor can feel like building a spaceship – tricky but totally possible! First, ensure you have all the tools, like wrenches and screwdrivers, ready. Next, follow these steps:

| Step | Action |

|---|---|

| 1 | Disconnect power. |

| 2 | Mount the motor securely. |

| 3 | Attach the belts. |

| 4 | Connect electrical wiring. |

| 5 | Test power and switch. |

Avoid common snafus like placing the motor too high or forgetting to check belt tension. A well-installed motor is key to avoiding future headaches – or worse, sawdust everywhere! Don’t forget, measure twice, install once!

Maintenance and Troubleshooting of Bandsaw Motors

Routine maintenance tasks to prolong motor life. Troubleshooting common motor issues and solutions.

Keeping your bandsaw motor happy is like giving it a spa day! Regular maintenance can make it last longer. Check the belts, clean the dust, and check the lubrication. This not only helps your saw perform better but makes you look like a pro! If things go wrong, don’t panic. Common issues like weird noises or overheating can often be fixed easily.

| Common Issue | Solution |

|---|---|

| Motor won’t start | Check the power supply and connections. |

| Weird sounds | Inspect bearings and belts for wear. |

| Overheating | Ensure proper ventilation and clean the fan. |

So, remember, a little TLC goes a long way with your bandsaw motor. It’s cheaper than therapy!

Upgrading Your Existing Bandsaw Motor

Factors to consider before upgrading. Benefits of upgrading to a more powerful motor.

Before swapping out your bandsaw motor, consider a few things. First, check the power rating. You want a motor that fits your cutting needs. Next, think about the space available in your workshop. A bigger motor may need more room, and don’t forget to match it with your bandsaw’s frame.

Upgrading means smoother cuts and less frustration. A powerful motor can slice through harder woods easily. Plus, your projects will look more professional. Isn’t it nice to impress your friends? A new motor could make all the difference!

| Factor | Details |

|---|---|

| Power Rating | Choose the motor that suits your cutting tasks. |

| Space | Make sure there’s enough room for your upgraded motor. |

Buying Guide for the Best Bandsaw Motor

Key questions to ask when purchasing a bandsaw motor. Where to find the best deals and discounts.

Choosing the right bandsaw motor can be tricky. Ask yourself these questions before buying:

- What power do I need? Consider the tasks you’ll do.

- Is it easy to install? Look for user-friendly options.

- What’s the warranty like? A good warranty shows quality.

To find the best deals, check these places:

- Online retailers, like Amazon and eBay

- Local hardware stores

- Manufacturer websites for specials

These tips will help you find the best bandsaw motor at a great price!

Customer Reviews and Testimonials

Summary of user experiences with various motors. Highlighting standout features praised by customers.

Users have shared a mix of experiences with different bandsaw motors. Many love how smooth and quiet some models run. “It’s like a ninja in my workshop!” one user giggled. Others appreciated the power, noting their saw cuts through wood like butter. Highlights include easy setup and reliable performance. Here’s a brief look at standout features praised by customers:

| Motor Model | Praised Features |

|---|---|

| PowerPro 3000 | Quiet performance, easy installation |

| CutMaster 500 | Strong cutting power, durable |

| WhisperCut 250 | Super smooth operation, lightweight |

Overall, customers are thrilled with their purchases and often relate their motors to trusty sidekicks on every project!

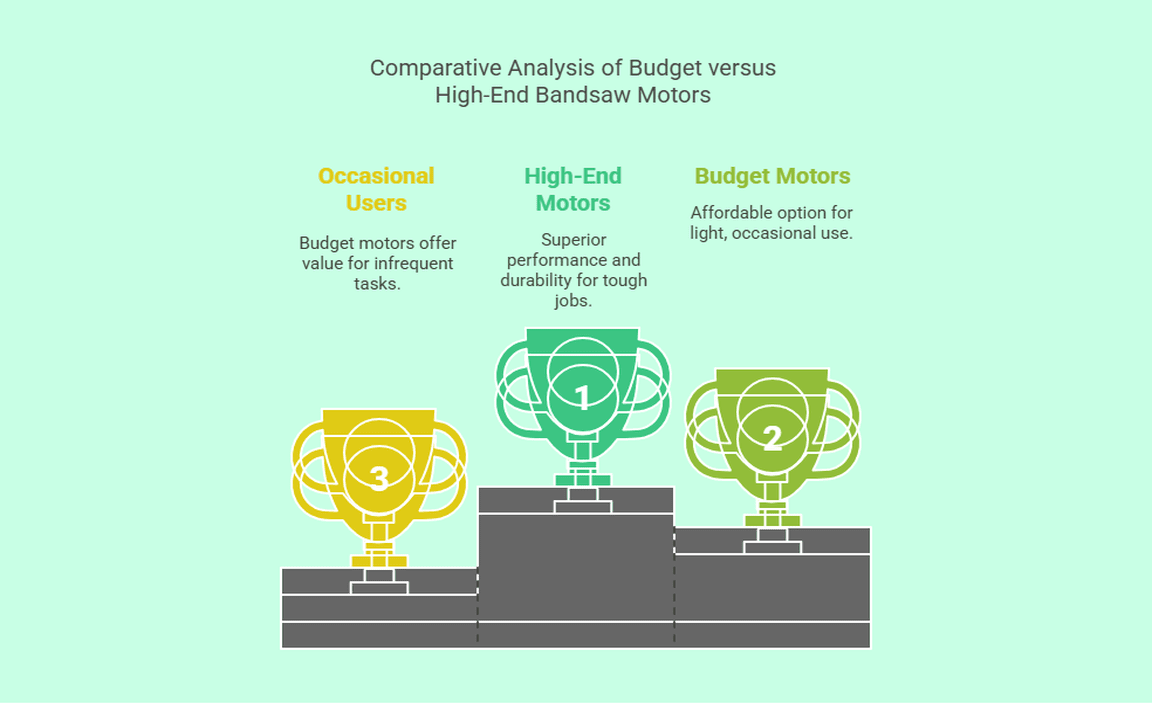

Comparative Analysis of Budget versus High-End Bandsaw Motors

Differences in performance and build quality. Value for money analysis for different user needs.

Choosing a bandsaw motor can feel challenging. Budget motors may save money, but they often lack durability and power. High-end motors, however, provide better performance and longer-lasting build quality. They also tend to run smoother and quieter, which many users appreciate. Here’s a quick comparison:

- Performance: Budget motors can struggle with heavy wood. High-end motors handle tough jobs with ease.

- Build Quality: Budget options may wear out quickly. High-end models are built to last.

- Value: For occasional users, a budget motor might suffice. For frequent use, a high-end motor is a better investment.

What are the best uses for budget vs. high-end bandsaw motors?

Budget motors work well for light tasks or hobby projects. High-end motors excel in professional workshops or heavy-duty tasks where performance matters.

Conclusion

In summary, choosing the best bandsaw motor boosts your cutting power and efficiency. Consider horsepower, speed, and durability when deciding. Remember, a quality motor makes your work easier and more enjoyable. You can explore different models online or at local stores. Don’t hesitate to ask for advice or read reviews to find the perfect fit for your projects!

FAQs

Sure! Here Are Five Related Questions On The Topic Of The Best Bandsaw Motor:

Sure! Here are five good questions about bandsaw motors: 1. What makes a bandsaw motor strong? A strong motor can cut through thick wood easily and quickly. 2. How do I pick the right motor size? You should choose a motor based on what you plan to cut. Bigger jobs need stronger motors. 3. Why are some motors quieter? Quieter motors have better design and materials. They make your work area more peaceful. 4. How can I make my bandsaw motor last longer? Keep it clean and check it often. Change the oil if it needs it. 5. Can I upgrade my old bandsaw motor? Yes, you can! Just make sure the new motor fits your bandsaw.

Sure! Please tell me what question you’d like me to answer.

What Are The Key Features To Look For In A Bandsaw Motor For Optimal Performance?

When choosing a bandsaw motor, look for power, speed, and size. A strong motor gives you better cuts. You want a motor that runs at a good speed for your projects. Also, make sure it fits your bandsaw’s size. Good motors have good cooling to prevent overheating.

How Does The Power Rating Of A Bandsaw Motor Influence Cutting Capabilities And Efficiency?

The power rating of a bandsaw motor shows how strong it is. A stronger motor can cut through thicker and harder materials more easily. This means you can work faster and finish your projects quicker. If the motor is weak, it may get stuck or take longer to cut, making it less efficient. So, a powerful motor helps improve cutting and saves time!

What Are The Advantages Of Using A Brushless Motor In Bandsaws Compared To Traditional Brushed Motors?

Using a brushless motor in bandsaws has some cool advantages. First, brushless motors don’t have brushes, so they last longer. This means you don’t have to replace parts as often. They also use less energy, which saves you money on electricity. Plus, brushless motors are quieter, making it nicer to work without loud noise.

How Do Different Types Of Bandsaw Motors (Single-Phase Vs. Three-Phase) Affect The Choice Of Bandsaw For Home Versus Industrial Use?

Bandsaws use different motors to work. Single-phase motors are good for home use because they plug into regular outlets. They are simple and easy to use. Three-phase motors are better for big jobs in factories. They need special power but can handle heavy work easily. So, choose single-phase for home and three-phase for work.

What Are Some Of The Top Brands Or Models Of Bandsaw Motors Currently Recommended By Experts In Woodworking?

Some of the top brands for bandsaw motors are Grizzly, Jet, and Rikon. Experts like these brands because they are strong and last a long time. You might also hear about the Laguna brand; it’s good for serious woodworking too. If you choose one of these, you’ll have a great tool for cutting wood!

Resource:

Woodworking Basics – Motor Types Explained: https://www.woodmagazine.com/materials-guide/motors

Energy Efficiency in Workshop Motors: https://www.energy.gov/eere/amo/motors-and-drives

Installing Electric Motors Safely: https://www.osha.gov/electrical-safety

Top Bandsaw Reviews and Buying Guide: https://www.popularwoodworking.com/reviews/