Have you ever tried to cut a tight curve with a bandsaw? It can be tricky, right? Many people struggle with this challenge. But with the right bandsaw setup, you can make those sharp turns effortlessly.

Imagine you’re crafting a beautiful wooden project. You need to make a tight radius cut. It’s exciting but also daunting. You want it to be perfect. What if I told you that the secret to success lies in how you set up your bandsaw?

Setting up your bandsaw properly can make all the difference. Using the right blade is crucial. A narrow blade works wonders for tight curves. But that’s not all. Proper tension and alignment help too. Together, these tips will turn a difficult task into a fun challenge.

Ready to learn more? Join us as we explore the best ways to set up your bandsaw for those tight radius cuts. You’ll be amazed at what you can create with just a few simple adjustments!

Table of Contents

Bandsaw Setup For Tight Radius Cuts: Essential Tips And Techniques

Bandsaw Setup for Tight Radius Cuts

Setting up a bandsaw for tight radius cuts can seem tricky, but it’s easier than you think. First, choose the right blade. A narrower blade works best for tight curves. Adjust the saw’s tension properly to avoid snags. Did you know that keeping the material steady while cutting makes a big difference? This holds your piece in place and ensures clean cuts. With these tips, you’ll master tight radius cuts in no time!

Understanding Tight Radius Cuts

Define tight radius cuts and their applications in woodworking and metalworking.. Discuss the importance of precision and accuracy in tight radius cuts..

Tight radius cuts are curves that bend sharply. You will often see these in woodworking and metalworking. They help shape materials in unique ways, like making furniture or designing parts for machines.

Precision and accuracy are key in tight radius cuts. Even small mistakes can lead to big problems. If the cut isn’t right, the piece may not fit together well. It’s important to measure carefully and take your time for the best results.

- Applications of Tight Radius Cuts:

- Creating intricate designs in furniture.

- Making precise parts for mechanical devices.

- Shaping metal for art or tools.

Why are precision and accuracy important in tight radius cuts?

Precision ensures that cuts meet design requirements, while accuracy helps pieces fit together seamlessly. A small error can make a big difference in your work.

Choosing the Right Bandsaw for Tight Radius Cuts

Highlight features to look for in bandsaws suitable for tight radius cutting.. Compare different bandsaw models best suited for these tasks..

Picking the right bandsaw makes tight radius cuts easier. Look for key features like a small blade width and variable speed control. These help with curves and detailed shapes. Compare models carefully. Some popular choices include:

- BandSaw Pro 2000: Great for detailed work with a fine blade.

- FlexCut Master: Has adjustable speeds for different projects.

- CurveKing 150: Lightweight and easy to maneuver around tight corners.

These options will make your cutting tasks smoother and more precise.

What features should you look for in a bandsaw for tight radius cuts?

Look for features like thin blades and adjustable speed settings to help with complex shapes. These features make it easier to handle curves.

Essential Tools and Accessories for Bandsaw Setup

List tools needed for setting up a bandsaw for tight radius cuts.. Discuss the importance of blade selection, including tooth count and width..

Setting up a bandsaw for tight radius cuts is like preparing for a dance-off—tools make all the difference! Essential items include a reliable bandsaw, the right blade, and measuring tools. Selecting the correct blade is key, too. A blade with the right tooth count and width helps achieve smooth cuts without any drama. Too wide and you might end up with a funky, jagged finish! Use the table below to keep track of what you need:

| Tool | Purpose |

|---|---|

| Bandsaw | Main tool for cutting |

| Blade | Choose one suitable for tight curves |

| Measuring tools | Ensure accuracy in cuts |

| Push sticks | Keep fingers safe |

With the right setup, your bandsaw can handle tight curves with ease. Remember, no one likes a rough cut—except maybe in a rock band!

Setting Up Your Bandsaw

Stepbystep guide on adjustments needed for tight radius cuts.. Explain the significance of tensioning the blade properly..

To set up your bandsaw for tight radius cuts, follow these simple steps. First, check the blade. Ensure it’s the right width for your cut. Next, tension the blade properly. This keeps the blade stable during cutting. Loose blades can bend and cause uneven cuts. Adjust the guides so they fit snugly against the blade. Lastly, test your setup with scrap wood. This helps confirm all adjustments are just right.

Why is proper tensioning of the blade important?

Proper tensioning is crucial for smooth cuts. A well-tensioned blade helps prevent bending and breaking. This ensures the blade stays straight, making tight radius cuts easier and safer.

Steps for Proper Blade Tensioning:

- Check the manufacturer’s guidelines for tension settings.

- Use a tension gauge for accuracy.

- Adjust until the gauge shows the correct tension.

- Test the tension by plucking the blade – a nice ping sound means it’s good!

Blade Selection for Tight Radius Cuts

Discuss various types of bandsaw blades and their suitability for tight radius cutting.. Explain the impact of blade width and tooth design on cutting performance..

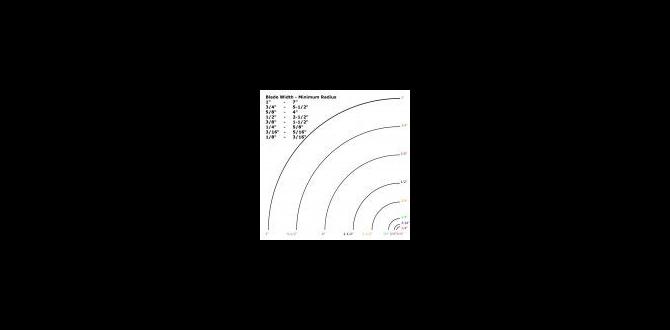

Choosing the right bandsaw blade is key for cutting tight curves. Thinner blades are often best for these tasks, as they can easily navigate bends. A blade width of 1/8 inch or less is ideal. Tooth design also matters; finer teeth provide smoother cuts on smaller curves, while larger teeth can speed through bigger ones. Each blade type has its strengths, making it important to select the right one for your project.

| Blade Type | Width | Best For |

|---|---|---|

| Contour Blade | 1/8” and narrower | Tight curves |

| Variable Tooth Blade | 1/4” to 1/2” | Curves and straight cuts |

| Resaw Blade | 1/2” to 3/4” | Thicker cuts, less tight bends |

Remember, the right blade can turn your bandsaw battle into a smooth sailing operation! Cutting those tight radii can feel like threading a needle—choose wisely!

Techniques for Achieving Tight Radius Cuts

Provide techniques and tips for maneuvering the material during cuts.. Discuss the use of jigs and fixtures to improve accuracy..

For those tricky tight radius cuts, you need some clever moves. First, use your hands wisely to guide the material smoothly. Think of it like guiding a puppy on a leash—gentle but firm! You can enhance your cuts with jigs and fixtures. These tools help keep everything in line, making sure your cuts look sharp and not like a toddler’s art project. Here’s a simple table to show how these techniques work:

| Technique | Description |

|---|---|

| Hand Control | Steady your hands for smooth cuts. |

| Using Jigs | Aligns your material for better accuracy. |

Remember, practice makes perfect. With each cut, your skills will sharpen, and soon you’ll be cutting like a pro!

Common Mistakes to Avoid

Highlight frequent errors made when setting up for tight radius cuts.. Provide solutions and recommendations to mitigate these mistakes..

When setting up for tight radius cuts, many folks make some classic mistakes. One big error is using the wrong blade. Picking a blade that’s too thick can ruin your project! Not aligning the blade properly is another common goof. Always ensure it’s straight as an arrow. Here’s a handy table to help you avoid these blunders:

| Mistake | Solution |

|---|---|

| Wrong blade type | Choose a thinner blade for tighter curves. |

| Poor alignment | Double-check the blade is perfectly aligned. |

| Cut too fast | Slow down to get clean, smooth curves. |

Remember, patience is key! If you mess up, just laugh it off and start again. Each mistake makes you a better woodworker!

Maintenance Tips for Optimal Performance

Discuss the importance of regular maintenance for bandsaws used for tight radius cuts.. Provide tips for blade care and machine upkeep..

Keeping your bandsaw in top shape is key for those tight radius cuts. Regular maintenance makes your saw last longer and work better. Check your blade often; a sharp one makes smooth cuts. Clean sawdust from the machine. It’s like giving it a bath! If your blade gets dull, replace it—no one likes a grumpy blade. Here’s a quick care checklist:

| Maintenance Task | Frequency |

|---|---|

| Inspect blade tension | Before every use |

| Clean saw dust | After every project |

| Replace dull blade | As needed |

Remember, a well-cared-for bandsaw is a happy bandsaw! Your cuts will thank you.

Safety Considerations when Performing Tight Radius Cuts

Outline essential safety precautions to follow when using a bandsaw.. Discuss proper personal protective equipment (PPE) to use during cutting..

Using a bandsaw for tight radius cuts can be fun, but safety is essential. Always wear proper personal protective equipment (PPE). This includes:

- Safety goggles to protect your eyes.

- Ear protection to shield your hearing.

- Dust mask to avoid inhaling sawdust.

- Cut-resistant gloves to protect your hands.

Always keep your hands clear of the blade. Stay focused and cut slowly. Never reach across the blade while it’s running. Remember, safety first!

What should I wear when using a bandsaw?

It’s important to wear safety goggles, gloves, ear protection, and a dust mask to protect yourself while cutting.

Conclusion

In conclusion, setting up a bandsaw for tight radius cuts requires proper blade selection, tensioning, and tracking. Ensure your workpiece is stable and move slowly for accuracy. Practice these tips to improve your cutting skills. You can also explore more resources or watch videos for visual guidance. With a little patience, you’ll master tight radius cuts in no time!

FAQs

Certainly! Here Are Five Related Questions On The Topic Of Bandsaw Setup For Tight Radius Cuts:

Sure! When you set up a bandsaw for tight turns, make sure to use a thin blade. Thin blades can bend easier. Also, try slowing down the saw so you don’t make mistakes. Always check that the blade is sharp before you start. Finally, keep your hands safe by staying clear of the moving blade.

Sure! Please give me a question, and I will answer it for you.

What Are The Essential Adjustments Needed On A Bandsaw To Effectively Cut Tight Radii?

To cut tight curves on a bandsaw, you need to make some key adjustments. First, change the blade to a narrow one. A narrow blade can turn easier. Second, adjust the tension so the blade is tight but not too tight. Finally, keep the speed slow to have more control while cutting. These changes will help you make better curves!

How Do Blade Selection And Tensioning Affect The Ability To Cut Tight Curves On A Bandsaw?

Choosing the right blade helps you cut tight curves better. A narrow blade works well for sharp turns. Tensioning is when you pull the blade tight. A tight blade stays straight and doesn’t wobble. This helps you make cleaner curves in your wood.

What Techniques Can Be Applied To Ensure Smooth And Accurate Cuts When Working With Tight Radii On The Bandsaw?

To make smooth and accurate cuts on tight curves with a bandsaw, you can follow a few simple steps. First, use a thin blade; it can turn easier. Second, go slow. This helps you keep control and follow the curves better. Lastly, always keep your hands clear of the blade and use push sticks if needed for safety.

How Does The Thickness Of The Material Being Cut Influence The Bandsaw Setup For Tight Radius Cuts?

The thickness of the material you cut can change how you set up the bandsaw. Thicker materials need more power and a stronger blade. For tight curves, you should use a thinner blade that bends easily. Make sure to adjust the speed of the saw too, so it cuts smoothly. This helps you make sharp turns without breaking the blade.

What Safety Precautions Should Be Taken When Performing Tight Radius Cuts On A Bandsaw?

When you make tight cuts on a bandsaw, be very careful. Always wear safety goggles to protect your eyes. Keep your hands away from the blade and use a push stick to guide the wood. Make sure the blade is sharp and well-tensioned to avoid accidents. Lastly, never rush; take your time to do it safely.