Have you ever faced issues with your bandsaw motor? It can be really frustrating. You might be in the middle of a project, and suddenly, your saw stops working. What do you do next? Troubleshooting a bandsaw motor can feel like a puzzle. But don’t worry! With a bit of guidance, you can solve most problems.

Many people think that motor troubles mean a costly repair. However, sometimes simple solutions make all the difference. Did you know that checking the power source is often the first step? It’s true! A loose wire or unplugged cord can cause the motor to fail. Imagine your surprise when you discover that the fix was that easy!

This article will walk you through common issues and solutions for bandsaw motors. By understanding a few key points, you’ll be able to keep your motor running smoothly. So, let’s dive in and make your bandsaw ready for your next cutting adventure!

Table of Contents

Bandsaw Motor Troubleshooting: Common Issues And Solutions

Bandsaw Motor Troubleshooting

Is your bandsaw motor making weird noises? Troubleshooting can help you fix it. First, check the power supply. A faulty plug or outlet can cause issues. Next, inspect the motor for unusual smells or visible damages. Sometimes, loose or frayed wires might be the problem. Regular maintenance can prevent many issues. Did you know that many bandsaw problems stem from lack of lubrication? Keep your bandsaw happy by checking it often!Common Signs of Bandsaw Motor Issues

Unusual noises and vibrations during operation. Overheating and excessive power draw.If your bandsaw motor is acting up, it might give you some clues. Watch for unusual noises, like grinding or squeaking, which could mean trouble. A cheerful motor should hum, not scream! Also, if the machine starts dancing (we call it ‘vibrating’), something’s off. Overheating is another bad sign. If the motor feels hotter than a summer day, it may be drawing too much power. This could lead to a meltdown, and no one wants their favorite tool gone in smoke!

| Signs | Description |

|---|---|

| Unusual Noises | Squeaks, grinding, or high-pitched sounds |

| Vibrations | Shaking or jittering during operation |

| Overheating | Excess heat and smoke |

| Power Draw | Increased electricity use |

Tools and Materials Needed for Troubleshooting

Essential tools for bandsaw maintenance. Recommended replacement parts and lubricants.To keep your bandsaw in tip-top shape, you need a few essential tools. Here’s what you should have:

- Wrench set for turning bolts and nuts.

- Multimeter to check electrical connections.

- Lubricants to keep parts moving smoothly.

- Replacement blades for cutting through tough materials.

Having these tools ready makes troubleshooting much easier. Don’t forget to use good machine oil for lubrication. It helps keep your saw running well, preventing problems later.

What are common tools for bandsaw maintenance?

Common tools include a wrench set, multimeter, lubricants, and replacement blades. These tools ensure your bandsaw operates smoothly and safely.

Checking Electrical Connections

Inspecting power supply and cords for damage. Testing switches and controls for functionality.Before using a bandsaw, check the power supply and electrical cords. Look for any worn spots or breaks in the cords. This can prevent your motor from running properly. Next, test the switches and controls. Turn them on and off to see if they work. Sometimes, a switch can get stuck or stop working altogether. Regular checks help keep your bandsaw in good shape!

What should I do if my bandsaw doesn’t start?

If your bandsaw won’t start, first check the power supply and cords. **Inspect for any damage or loose connections.** Then test the switches to see if they function correctly.

Quick Tips:

- Examine cords for fraying or cuts.

- Test each switch before using the saw.

- Ensure the power source is reliable.

Motor Inspection and Diagnosis

Examining the motor for visible wear or damage. Performing electrical tests to check motor health.First off, take a good look at the motor for any signs of wear or damage. Cracks, rust, or loose parts can spell trouble. If it looks like it has been through a wrestling match, it probably needs help! Next, you’ll want to perform some electrical tests. This checks if the motor is healthy and ready to rock. A multimeter is your best buddy here. Remember, keeping it in tip-top shape is key to good vibes!

| Inspection Step | What to Look For |

|---|---|

| Visible Wear | Cracks, rust, or loose connections |

| Electrical Tests | Voltage and resistance checks |

Troubleshooting Motor Overheating

Identifying causes of overheating in motors. Solutions and adjustments to prevent overheating.When a motor overheats, it can be a big problem. Common causes include dust buildup, low lubrication, and overloading. To fix this issue, keep your motor clean, check oil levels regularly, and avoid pushing it too hard. If overheating happens often, consider adjusting the load or upgrading the fan. This way, your bandsaw motor can work smoothly.

What should I do if my motor overheats?

To cool down your motor, check for dust, ensure it has enough lubrication, and reduce heavy loads. These steps will help keep it from overheating again.

Common causes of motor overheating:

- Dust and debris

- Inadequate lubrication

- Overloading

Addressing Vibration and Noise Issues

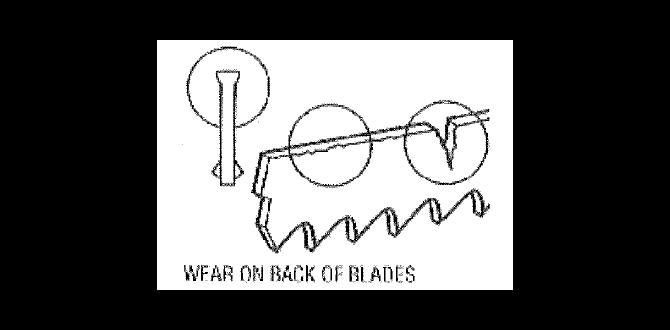

Diagnosing the source of vibrations in the bandsaw. Tips for reducing noise and improving performance.Vibrations and noise can mean trouble for your bandsaw. First, check for loose parts. Tighten bolts and screws to keep everything snug. Next, look at the blade. A damaged or dull blade can cause noise and vibration. Replace or sharpen it if needed. You might also want to clean the saw and check for debris blocking its path. These steps can help improve your saw’s performance.

What causes vibration in a bandsaw?

The main causes of vibration are loose parts, dull blades, and misalignment. When these issues happen, you can feel or hear problems during use.

Tips to reduce noise:

- Regularly check and tighten all screws.

- Keep the blade sharp and clean.

- Ensure the bandsaw is on a flat surface.

When to Seek Professional Help

Signs that indicate the need for professional repair. How to choose a qualified technician for motor servicing.It’s important to know when to call for help. If your bandsaw makes strange noises, smells odd, or won’t start, it’s time to get a professional. These signs can mean serious issues. Use these tips to find a good technician:

- Check for reviews or ask friends.

- Look for someone with experience in bandsaws.

- Make sure they are certified and insured.

Choosing wisely can save you time and money. Don’t wait too long; getting help early can prevent bigger problems.

What are common signs that you need repair?

If your motor runs loud, overheats, or stops suddenly, you likely need repairs. Listen to your machine!

Preventative Maintenance Tips for Bandsaw Motors

Regular maintenance practices to enhance motor longevity. Recommended maintenance schedule for optimal performance.Want your bandsaw motor to last longer? Regular maintenance is the secret sauce! Check the belts and pulleys for wear often. A loose belt can make your motor grumpy, like a cat without dinner. You should also clean the motor every once in a while to keep dust away. Consider keeping a checklist for maintenance tasks.

| Maintenance Task | Frequency |

|---|---|

| Check belts and pulleys | Every month |

| Clean the motor | Every three months |

| Oil bearings | Every six months |

Following this schedule can keep your motor happy and healthy. Remember, a well-maintained bandsaw motor will perform like a rock star! So, love your tools, and they will love you back!

Conclusion

In summary, troubleshooting your bandsaw motor can solve many problems. First, check the power supply, belts, and switches. Next, inspect the motor for any signs of damage. You can often fix issues with simple tools. If you’re still stuck, consider searching for helpful guides or videos online. Remember, practice makes perfect, so keep learning and improving your skills!FAQs

Sure! Here Are Five Related Questions On Bandsaw Motor Troubleshooting:Sure! If your bandsaw motor isn’t working, first check if it’s plugged in. You should also look for blown fuses or tripped circuit breakers. Next, listen for any strange noises when you try to start it. If it still won’t work, the motor might be broken and will need repairs. Always ask an adult for help!

Sure! Please give me a question to answer.

What Are The Common Symptoms Of A Failing Bandsaw Motor?If your bandsaw motor is failing, you might notice it makes weird noises, like grinding or buzzing. It could also run more slowly than usual or suddenly stop working. Sometimes, it might overheat and smell funny. If you see sparks, that’s a big sign something is wrong. Always be careful and get help if you notice these problems!

How Can You Determine If The Motor Is Receiving Power During Operation?To check if the motor is getting power, you can look for a few signs. First, listen for a humming noise when you turn it on. If the motor runs and makes noise, it’s likely getting power. You can also feel the motor; if it’s warm, that’s another good sign. Finally, if it moves or spins, it’s definitely receiving power!

What Steps Should Be Taken To Troubleshoot Unusual Noises Or Vibrations From The Bandsaw Motor?To fix unusual noises or vibrations from the bandsaw motor, first, turn off the machine. Then, check if the motor is securely mounted. Next, look for loose parts or screws. You should also examine the belt for any damage. If these steps don’t help, ask an adult for assistance.

How Do You Test The Motor’S Capacitor For A Bandsaw, And What Are The Signs Of A Faulty Capacitor?To test the motor’s capacitor on a bandsaw, first make sure the power is off and unplug it. You can use a multimeter to check the capacitor. Set the multimeter to the right settings and touch the probes to the capacitor’s terminals. If the meter doesn’t show a reading or if it shows a very low reading, the capacitor is likely bad. Signs of a faulty capacitor include strange noises, a burning smell, or the motor not starting at all.

What Safety Precautions Should Be Followed While Troubleshooting Or Repairing A Bandsaw Motor?When you work on a bandsaw motor, first unplug it to avoid electric shock. Always wear safety glasses to protect your eyes from dust. Use gloves to keep your hands safe from sharp parts. Make sure your workspace is clean and dry to prevent slips or falls. Lastly, ask an adult for help if you’re unsure about anything.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On Bandsaw Motor Troubleshooting:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! If your bandsaw motor isn’t working, first check if it’s plugged in. You should also look for blown fuses or tripped circuit breakers. Next, listen for any strange noises when you try to start it. If it still won’t work, the motor might be broken and will need repairs. Always ask an adult for help!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me a question to answer.”}},{“@type”: “Question”,”name”: “What Are The Common Symptoms Of A Failing Bandsaw Motor?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your bandsaw motor is failing, you might notice it makes weird noises, like grinding or buzzing. It could also run more slowly than usual or suddenly stop working. Sometimes, it might overheat and smell funny. If you see sparks, that’s a big sign something is wrong. Always be careful and get help if you notice these problems!”}},{“@type”: “Question”,”name”: “How Can You Determine If The Motor Is Receiving Power During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if the motor is getting power, you can look for a few signs. First, listen for a humming noise when you turn it on. If the motor runs and makes noise, it’s likely getting power. You can also feel the motor; if it’s warm, that’s another good sign. Finally, if it moves or spins, it’s definitely receiving power!”}},{“@type”: “Question”,”name”: “What Steps Should Be Taken To Troubleshoot Unusual Noises Or Vibrations From The Bandsaw Motor?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix unusual noises or vibrations from the bandsaw motor, first, turn off the machine. Then, check if the motor is securely mounted. Next, look for loose parts or screws. You should also examine the belt for any damage. If these steps don’t help, ask an adult for assistance.”}},{“@type”: “Question”,”name”: “How Do You Test The Motor’S Capacitor For A Bandsaw, And What Are The Signs Of A Faulty Capacitor?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To test the motor’s capacitor on a bandsaw, first make sure the power is off and unplug it. You can use a multimeter to check the capacitor. Set the multimeter to the right settings and touch the probes to the capacitor’s terminals. If the meter doesn’t show a reading or if it shows a very low reading, the capacitor is likely bad. Signs of a faulty capacitor include strange noises, a burning smell, or the motor not starting at all.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Followed While Troubleshooting Or Repairing A Bandsaw Motor?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you work on a bandsaw motor, first unplug it to avoid electric shock. Always wear safety glasses to protect your eyes from dust. Use gloves to keep your hands safe from sharp parts. Make sure your workspace is clean and dry to prevent slips or falls. Lastly, ask an adult for help if you’re unsure about anything.”}}]}