Have you ever tried to make a perfect dovetail joint? It’s tricky! Many woodworkers strive for this classic joint, known for its strength and beauty. But what if there was a tool that could help? Enter the bandsaw for dovetail joints. This amazing tool changes the game.

Using a bandsaw, you can cut precise shapes without much effort. Imagine how much faster your woodworking could be! Picture yourself working on a beautiful drawer for your favorite piece of furniture. With the right cuts, your project will come together in no time.

Many people don’t realize how helpful a bandsaw can be. It’s not just for big, heavy jobs. You can use it for small, detailed cuts too! Plus, it can help you explore your creativity. Want to try new designs for your dovetail joints? A bandsaw makes it easy.

In this article, we will dive into how to use a bandsaw for dovetail joints. Discover tips, tricks, and common mistakes to avoid. By the end, you’ll feel ready to take on your next woodworking challenge with confidence!

Table of Contents

Best Bandsaw For Dovetail Joints: Top Picks & Tips

Bandsaw for Dovetail Joints

Dovetail joints are among the strongest wood connections. Using a bandsaw can make creating these joints easier and more precise. A bandsaw helps you cut the complex angles needed for tight fitting. Imagine crafting your own furniture with beautiful dovetail joints! Did you know that woodworking with a bandsaw can save time and reduce waste? With the right setup, you’ll master these joints in no time. Start your woodworking journey today!

Understanding Dovetail Joints

Definition and purpose of dovetail joints in woodworking. Historical significance and applications in furniture making.

Dovetail joints are strong connections used in woodworking. They fit together like puzzle pieces. This design keeps the wood from pulling apart. Dovetail joints have a long history, dating back to ancient Egypt. Craftsmen used them in furniture for added strength and beauty. Today, they are popular in cabinets and drawers.

What is the purpose of dovetail joints?

The main purpose of dovetail joints is to create strong, durable connections in wood. They prevent the joints from coming apart even under stress.

Historical Significance:

- Used in furniture making for centuries.

- Symbols of quality craftsmanship.

- Helped in building sturdy structures.

This unique design remains popular today, showcasing both function and beauty. Many woodworkers appreciate the skill it takes to make dovetail joints.

Why Use a Bandsaw for Dovetail Joints?

Advantages of using a bandsaw over traditional methods. Precision and efficiency in creating dovetail joints.

Using a bandsaw for dovetail joints offers big benefits. It cuts quickly and accurately, making projects easier. Here are some advantages:

- Precision: Bandsaws create clean cuts, ensuring perfect fitting joints.

- Efficiency: You can make complex shapes faster than traditional methods.

- Less Waste: The cuts are exact, reducing leftover wood.

- Safer: Modern bandsaws come with safety features, lowering the risk of accidents.

With these benefits, a bandsaw is a smart choice for woodworkers!

Why choose a bandsaw over traditional methods?

A bandsaw is faster and more accurate, making it ideal for dovetail joints. This saves time and produces better results.

Choosing the Right Bandsaw for Dovetail Joints

Key features to look for in a bandsaw. Recommended bandsaw models for intricate joinery.

Looking for the perfect bandsaw for dovetail joints? Key features matter! Ensure it has a good blade guide and a strong motor. A wide throat and adjustable speed are also vital for precise cuts. Some recommended models include the Grizzly G0555LX and the Laguna Tools 14bx. These bandsaws are like superheroes for intricate woodworking. They make dovetails feel as easy as pie!

| Model | Features |

|---|---|

| Grizzly G0555LX | Powerful motor, great for fine cuts |

| Laguna Tools 14bx | High precision and easy to adjust |

Setting Up Your Bandsaw for Dovetail Joints

Essential setup steps and adjustments. Blade selection and tensioning for optimal performance.

Getting your bandsaw ready for dovetail joints can be fun and straightforward! First, check that your table is level. A wobbly table leads to wobbly cuts. Then, choose the right blade. A narrow blade works best for those delightful curves. Don’t forget to tension the blade well; a loose blade is like a floppy noodle. Make adjustments to the guides, keeping them close to the blade. This helps keep everything on track. Finally, use a scrap piece of wood for a test cut. If it’s all good, you’re set to make perfect dovetail joints!

| Step | Description |

|---|---|

| Level the Table | Make sure it does not wobble like a jelly on a plate! |

| Choose the Blade | Narrow blades work best for those beautiful dovetails. |

| Tension the Blade | Think of your blade like a string on a guitar; it needs to be tight! |

| Adjust the Guides | Keep them close; they’re your support team! |

| Test Cut | Use scrap wood for practice; no one wants a “oops” moment! |

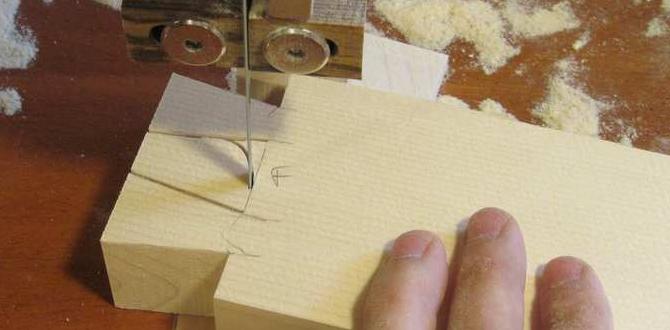

Techniques for Cutting Dovetail Joints with a Bandsaw

Stepbystep process for cutting tails and pins. Tips for maintaining accuracy and consistency.

Cutting dovetail joints with a bandsaw can be fun and rewarding! Start by marking your wood clearly for the tails and pins. A good tip is to use a square for neat lines. Make sure you set your bandsaw’s fence right for consistent cuts. Remember, accuracy is key! A steady hand helps, too. If you wobble, the pieces might not fit well. Keep your blades sharp, or they’ll leave “dovetail despair!”

| Step | Description |

|---|---|

| 1 | Mark wood for tails and pins |

| 2 | Set bandsaw’s fence |

| 3 | Cut tails first, then pins |

| 4 | Check fit, adjust if needed |

If you follow these steps, you’re bound to create beautiful dovetail joints. Remember, “Measure twice, cut once!” It’s like magic, but without the wand!

Common Mistakes to Avoid

Misalignment and its impact on joint quality. Overcoming blade drift and other challenges.

Misalignment can be a sneaky troublemaker when working on dovetail joints. If your saw isn’t lined up just right, those tight-fitting joints might end up looking more like a jigsaw puzzle than a masterpiece! A wonky cut can ruin a whole project, so check your setup before cutting.

Blade drift is another pesky problem. It can send your cuts off course faster than a cat sees a laser pointer! But, don’t fret. You can tackle this with some practice and adjustments to your blade angle.

| Issue | Impact | Solution |

|---|---|---|

| Misalignment | Poor joint fit | Double-check alignment |

| Blade Drift | Wavy cuts | Adjust blade angle |

Remember, a little patience and attention can go a long way in avoiding these mistakes. Happy woodworking!

Finishing Touches on Dovetail Joints

Sanding and cleaning up joint edges. Applying finishes to enhance durability and aesthetics.

After cutting your dovetail joints, it’s time for the finishing touches. Start by sanding the edges carefully. This makes everything smooth and nice to touch. Use fine sandpaper for the best results. Next, apply a finish like oil or varnish. This will protect the wood and make it shine. It also adds style to your project. A good finish can help the joints last longer. Remember, the better you finish, the more beautiful your work will be!

How can you enhance the look and durability of dovetail joints?

To improve the appearance and strength, focus on sanding and applying finishes. Sanding smooths out rough edges, while finishes protect wood and enhance its natural beauty.

- Use fine sandpaper for smoothness.

- Choose a durable finish like oil or varnish.

- Apply multiple thin coats for the best results.

Maintenance and Care for Your Bandsaw

Routine maintenance tips for longevity. Troubleshooting common bandsaw issues.

Taking care of your bandsaw can make it last longer and work better. Regularly check the blade for any cracks or dull spots. Clean the table and the areas around the blade to prevent sawdust build-up. You don’t want your bandsaw to choke on dust like a fish on a dry land! If you hear strange noises or the blade wobbles, you might need to adjust the tension. Below are some quick tips for maintenance:

| Routine Maintenance Tips | Common Issues |

|---|---|

| Keep the blade sharp | Blade not aligned? Tighten screws. |

| Clean regularly | Strange noise? Check for loose parts. |

| Check belt tension | Blade slipping? Adjust tracking. |

By doing these simple tasks, you won’t just have a working bandsaw—you’ll have a tool that feels like new! Remember, a happy bandsaw makes for happy dovetail joints!

Additional Resources and Tools for Woodworkers

Recommended books and online courses on dovetail joinery. Essential tools and equipment to complement your bandsaw usage.

Woodworking is a fun hobby! To learn more about dovetail joints, here are some recommended books and online courses:

- “The Complete Manual of Woodworking” – Great for all levels.

- “Woodworking Basics” – Focuses on essential skills.

- Online Course: “Mastering Dovetail Joints” – Step-by-step video lessons.

To use your bandsaw for dovetail joints effectively, consider these essential tools:

- Chisels for cleaning up joints.

- Measuring tools for accuracy.

- Wood glue for strong connections.

These resources will help sharpen your skills and make your woodworking projects even better!

What are good resources for dovetail joinery?

Books and online courses are excellent resources for learning dovetail joinery. They provide valuable tips and techniques for all skill levels, helping you become more confident in your woodworking journey.

Conclusion

In summary, a bandsaw is a great tool for making dovetail joints. It helps you cut precise shapes easily. With practice, you can create strong and beautiful joints for your projects. Remember to choose the right blade and set up your bandsaw correctly. For more tips and techniques, consider reading guides or watching videos on bandsaw use!

FAQs

What Are The Advantages Of Using A Bandsaw For Cutting Dovetail Joints Compared To Other Methods?

Using a bandsaw to cut dovetail joints is faster than using a hand saw. You can cut more accurately, which means the pieces fit together better. It’s also easier on your arms because you don’t have to push as hard. Plus, we can make repeat cuts quickly, so it saves time on big projects. Overall, a bandsaw helps us create strong joints more efficiently!

What Blade Types And Settings Are Recommended For Achieving Clean Cuts When Using A Bandsaw For Dovetail Joints?

To cut dovetail joints cleanly on a bandsaw, you should use a fine-tooth blade. A blade with 10 to 14 teeth per inch works well. Make sure your bandsaw is set to the right speed, usually a slower speed is better for wood. Also, keep the guides tight to help keep the blade straight. This way, you’ll get nice, clean cuts!

How Can I Accurately Set Up My Bandsaw For Making Precise Dovetail Cuts?

To set up your bandsaw for dovetail cuts, start by checking the blade. Make sure it’s sharp and the right size. Next, adjust the guides so the blade runs straight. Then, set the table at the right angle for your cut. Finally, practice on some scrap wood to make sure everything works well before cutting your real project.

What Are Some Common Mistakes To Avoid When Using A Bandsaw For Cutting Dovetail Joints?

When using a bandsaw to cut dovetail joints, you should avoid making these mistakes. First, always measure twice before cutting to ensure your pieces fit together. Next, keep your hands away from the blade for safety. Also, use a sharp blade because a dull one can mess up your cuts. Finally, take your time and don’t rush; careful cutting leads to better results.

Can A Bandsaw Be Used Effectively For Both Softwood And Hardwood Dovetail Joints, And Are There Any Adjustments Needed For Each?

Yes, you can use a bandsaw for both softwood and hardwood dovetail joints. Softwood cuts easily, while hardwood needs more care. You might need to adjust the blade speed for hardwood, making it slower to avoid mistakes. Keep your hands steady to get neat cuts every time.