Have you ever wondered how woodworkers cut through tough hardwood? One essential tool they use is the bandsaw. But did you know that not all bandsaw blades are the same? There are different types of bandsaw blades, and each one works better for specific tasks.

Imagine trying to slice a big stack of oak and struggling with the wrong blade. Frustrating, right? Using the right bandsaw blade for hardwood makes cutting easier and cleaner. It’s like using the right key to unlock a door.

In this article, we will explore the various bandsaw blade types for hardwood. You’ll learn which blades suit different hardwoods and projects. By the end, you’ll feel confident choosing the best blade for your next woodworking adventure!

Table of Contents

Bandsaw Blade Types For Hardwood: A Comprehensive Guide

bandsaw blade types for hardwood

Choosing the right bandsaw blade for hardwood can make a big difference. Different types of blades serve unique purposes. For example, skip-tooth blades cut quickly but leave rough edges, perfect for rough cuts. Meanwhile, hook-tooth blades work well for deeper cuts. Did you know that the width of the blade affects the curve you can cut? It’s like picking the right tool for a puzzle! Finding the right blade can enhance your woodworking projects greatly.Understanding Bandsaw Blades

Definition and purpose of bandsaw blades. Importance of choosing the right blade for hardwood.Bandsaw blades are special tools used for cutting wood. They spin around a wheel and can slice through tough pieces like hardwood with ease. Choosing the right blade is super important. Using a blade made for hardwood helps make clean cuts and keeps your project neat. Imagine using a spaghetti cutter on a brick! It wouldn’t work well at all, right? So, having the right bandsaw blade can save you time and effort.

| Blade Type | Best Use |

|---|---|

| Hook Tooth | Fast cuts in thick hardwoods |

| Skip Tooth | Curved cuts and resawing |

| Regular Tooth | General purpose for various woods |

Pick your blade wisely, and you’ll become the woodwork wizard of your block! Remember, a good blade is like a superhero cape; it helps you do your job better!

Types of Bandsaw Blades

Description of various bandsaw blade types available. Comparison of their features and uses.There are several bandsaw blade types, each designed to tackle different challenges. Some blades are thick and strong for cutting through hardwood like a hot knife through butter, while others are thinner for fine, intricate cuts. Choosing the right blade matters! A good choice can save you from spending hours on woodwork that feels like wrestling a bear.

| Blade Type | Features | Uses |

|---|---|---|

| Resaw Blade | Wide, thick teeth | Cutting thick boards into thinner slices |

| Curved Blade | Flexible, narrow | Making curved cuts |

| Combo Blade | Versatile, balanced teeth | General purpose cuts |

In short, your choice of blade can make or break your project. Always pick wisely, unless you enjoy chaos in your workshop! Keep these tips in mind, and your woodworking will be a piece of cake—without the crumbs!

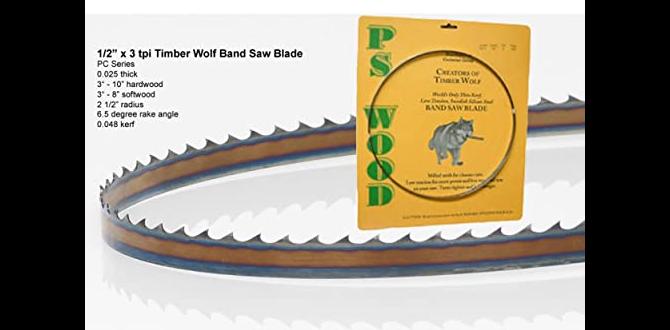

Teeth Configuration

Explanation of tooth counts and shapes (hook, skip, and regular). How tooth configuration affects performance on hardwood.Teeth on bandsaw blades come in different shapes and counts, much like different ice cream flavors! The most common types are hook, skip, and regular. Hook teeth have a deeper bite, perfect for ripping through hardwood like a hot knife through butter. Skip teeth, on the other hand, are like the cheetahs of the blade world—fast and good for cutting curves! Regular teeth are the all-rounders, handling most tasks efficiently. Choosing the right configuration can affect how smoothly each cut goes. Here’s a quick look:

| Tooth Type | Best For | Performance |

|---|---|---|

| Hook | Ripping | Fast cuts |

| Skip | Curved cuts | Quick and clean |

| Regular | General purpose | Versatile |

Choosing the right tooth shape is key. It can make cutting through hardwood feel like slicing cake or more like a battle with a stubborn piece of wood!

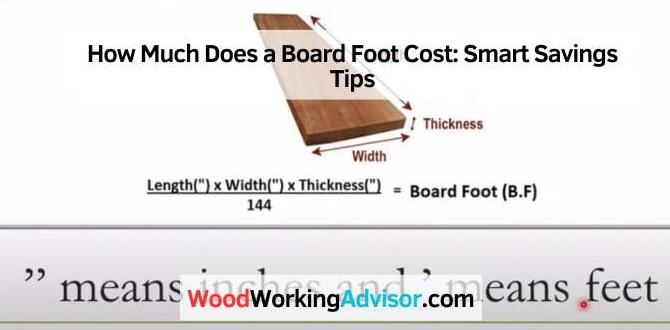

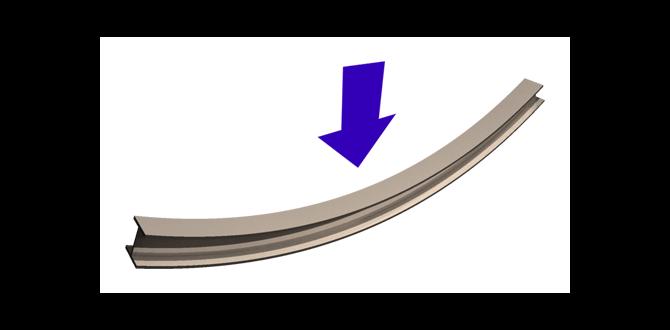

Blade Width and Thickness

Impact of blade width on cutting ability and precision. Recommended thickness for different hardwood applications.The width of a bandsaw blade cuts through wood like a hot knife through butter! A wider blade can handle larger cuts, giving you *power* and *control*. But, if you’re looking for precise cuts, a thinner blade is your best buddy. It’s like trying to squeeze through a door. A little wiggle makes all the difference!

| Blade Thickness (inches) | Recommended Use |

|---|---|

| 1/8 | Intricate curves and detailed work |

| 1/4 | General cutting for hardwoods |

| 3/8 | Thicker hardwoods and more robust cuts |

Choosing the right thickness helps you tackle tough woods without fuss. Remember, precision comes from the right tools, and a happy woodworker knows their blades!

Choosing the Right Blade for Specific Hardwood Types

Recommendations for popular hardwoods (oak, maple, cherry, etc.). Factors to consider when selecting a blade for specific projects.Picking the perfect blade for your hardwood project is like finding a tasty cookie in a jar! It’s all about matching the blade type to your wood. For oak, a thicker blade works best to cut through its toughness. If you’re tackling maple, a fine-tooth blade will help give you that smooth edge. And for the sweet, rich grain of cherry, a medium blade does wonders. Remember, choosing the right blade can make your cutting fun rather than frightening!

| Hardwood Type | Recommended Blade Type |

|---|---|

| Oak | Thicker Blade |

| Maple | Fine-Tooth Blade |

| Cherry | Medium Blade |

Before you start cutting, think about the project size and the wood’s grain. These simple tips can turn a daunting task into a delightful experience!

Maintenance and Care Tips

Best practices for blade cleaning and maintenance. How to extend the lifespan of bandsaw blades used on hardwood.Keeping your bandsaw blade in tip-top shape is key for cutting hardwood smoothly. Regular cleaning prevents pitch buildup, which could turn your saw into a sticky mess. Use a soft brush or cloth to remove debris, and don’t forget to wipe down the blade with a bit of oil. This keeps it from rusting faster than you can say “sawdust”! To extend the lifespan of your blades, always keep them sharp. Dull blades are like tired puppies—no fun at all! Check your tension and alignment too; a happy blade cuts best.

| Tip | Description |

|---|---|

| Clean Regularly | Brush off pitch and dirt to maintain sharpness. |

| Use Oil | Wipe blades with oil to prevent rust. |

| Check Tension | Ensure proper tension for better cuts. |

| Keep Blades Sharp | Sharp blades are fun and safe! |

Common Mistakes to Avoid

Typical errors in bandsaw blade selection and usage. Tips for optimizing performance and achieving better results.Choosing the wrong bandsaw blade can feel like wearing mismatched socks to a party—uncomfortable and a little embarrassing. Many folks overlook blade tooth count, thinking “more teeth equals better cuts.” Not always! Too many teeth can cause the wood to heat up. Also, using a blade for the wrong material? That’s a surefire way to ruin a good day! Keep blades clean and well-lubricated for smooth performance. Here’s a quick table for easy reference:

| Common Mistake | Solution |

|---|---|

| Using the wrong tooth count | Match teeth to material type! |

| Ignoring blade tension | Adjust for smoother cuts! |

| Neglecting maintenance | Keep it clean and sharp! |

Conclusion

In summary, choosing the right bandsaw blade for hardwood is crucial. You need blades that cut cleanly and resist wear. Look for options like skip tooth or hook tooth designs for efficiency. Experiment with different types to find what works best for you. For more tips and insights, keep reading or talk to experts at your local hardware store!FAQs

Sure! Here Are Five Questions Related To Bandsaw Blade Types For Hardwood:Sure! Here are five questions related to bandsaw blade types for hardwood: 1. **What are bandsaw blades?** Bandsaw blades are long, thin pieces of metal used to cut wood. They go around two wheels in the bandsaw. 2. **Why choose the right blade for hardwood?** Choosing the right blade helps you cut wood better. It makes cleaner cuts and helps your saw last longer. 3. **What is a teeth count?** Teeth count is how many sharp points are on the blade. More teeth mean finer cuts, which is good for hardwood. 4. **What is the best blade type for thick hardwood?** For thick hardwood, a blade with fewer teeth and wider set is best. It cuts through thick wood faster. 5. **Can I use the same blade for different woods?** You can use the same blade, but it’s better to match the blade to the type of wood. This helps with better cuts.

Sure! Please ask your question, and I’ll do my best to provide a simple and clear answer.

What Types Of Teeth Configurations Are Best Suited For Cutting Hardwood With A Bandsaw?To cut hardwood with a bandsaw, you need teeth that are sharp and spaced apart. A configuration with fewer teeth per inch, known as TPI, helps. This setup allows the saw to cut through tough wood better. We should also look for teeth that have a hook shape. This shape helps the saw bite into the wood easily.

How Does The Width Of A Bandsaw Blade Affect Its Performance When Cutting Hardwood?The width of a bandsaw blade matters a lot when cutting hardwood. A wider blade cuts straight and quickly through thick wood. It helps you make smooth cuts without breaking. A thinner blade can turn easily, but it might bend or break with hard wood. So, if you’re cutting thick hardwood, use a wider blade for better performance.

What Are The Key Differences Between Carbon Steel And Bi-Metal Bandsaw Blades For Hardwood Applications?Carbon steel bandsaw blades are made from a softer metal. They are great for cutting softer woods. Bi-metal bandsaw blades combine two types of metals. They stay sharp longer and cut through hardwood better. If you want smooth cuts in tough wood, choose the bi-metal blades!

How Important Is The Kerf Width When Selecting A Bandsaw Blade For Hardwood Cutting?The kerf width is very important when you choose a bandsaw blade. The kerf is the width of the cut the blade makes. A wider kerf means more wood is removed, which can waste material. If you want to save wood, a smaller kerf is better. So, think carefully about the kerf width when cutting hardwood!

What Factors Should Be Considered When Choosing The Right Bandsaw Blade Material For Specific Hardwood Species?When picking a bandsaw blade for hardwood, think about the type of wood you will cut. Some woods are harder than others, so you need a strong blade. Look at how thick the wood is; thicker wood needs tougher blades. Also, consider how smooth you want the cut to be. The right blade will help you do a great job!