Have you ever tried to cut wood with a bandsaw, only to find it doesn’t work right? Frustrating, isn’t it? Bandsaws are great tools, but they need special care. One common issue that many people face is alignment problems. When the blade isn’t lined up properly, it can lead to messy cuts and wasted wood.

Did you know that a small misalignment can make a big difference? Just a slight shift can turn a clean cut into a disaster. This is why learning about bandsaw alignment troubleshooting is so important. It can save you time, money, and lots of headaches.

Imagine trying to create the perfect piece of furniture, only to be held back by your bandsaw. What if you could quickly fix those annoying problems? Well, you can! In this article, we will explore easy steps to troubleshoot your bandsaw and get it back on track. Get ready to make your woodworking projects smoother and more enjoyable!

Table of Contents

Bandsaw Alignment Troubleshooting: Tips For Accurate Sawing

Bandsaw Alignment Troubleshooting

Is your bandsaw cutting crooked? Bandsaw alignment troubleshooting can help solve that problem! Proper alignment keeps cuts straight and improves your woodwork. First, check the blade tension and tracking. Uneven blade tension can cause issues. Next, examine the wheels for alignment. Just a small bend can lead to big problems. Finally, make sure your table is square to the blade. With these tips, your bandsaw will perform better. Who knew fixing a bandsaw could be so simple?Understanding Bandsaw Alignment

Importance of proper bandsaw alignment for efficiency and precision. Common signs of misalignment in bandsaws.Proper bandsaw alignment is key for smooth cuts and happy woodworking! Imagine trying to slice a pizza with a wobbly knife—that’s how a misaligned bandsaw feels. Without it, you might see uneven edges and more sanding than you bargained for. Watch for signs like strange noises or vibrations. Ignoring these could lead to a very frustrating woodworking session!

| Signs of Misalignment | What to Look For |

|---|---|

| Uneven Cuts | Your board might look more like a banana than a straight plank! |

| Excessive Vibration | Your bandsaw might dance a little too much while cutting! |

| Strange Noises | If it sounds like a rock concert, something’s off! |

Keep an eye out for these clues to ensure your bandsaw cuts as straight as an arrow! Remember, an aligned bandsaw is a happy bandsaw!

Tools Required for Bandsaw Alignment

Essential tools for effective bandsaw alignment troubleshooting. How to select the right tools for your bandsaw model.To align your bandsaw correctly, you need some handy tools. These tools will help make troubleshooting easier. Here are a few essential ones:

- Ruler – For measuring distances accurately.

- Tension Gauge – To check blade tension.

- Square – To ensure the blade is perpendicular to the table.

- Caliper – For precise thickness measurements.

- Level – To keep the bandsaw stable and straight.

Pick tools that match your bandsaw model. This way, you get the best results.

What are some tools to troubleshoot bandsaw alignment?

Essential tools include a ruler, tension gauge, square, caliper, and level. These tools help ensure accuracy and proper alignment.

Step-by-Step Alignment Procedure

Detailed steps to align the bandsaw blade correctly. Best practices to ensure accuracy throughout the process.Aligning your bandsaw blade is like tuning a guitar; it needs to be just right! First, turn off the saw and unplug it—safety first! Check that the blade is properly tensioned. Next, adjust the blade guides. Make sure they are close but not touching. A gap is good; think of it like giving the blade a little room to breathe!

After that, use a square to check if the blade is perpendicular to the table. If not, adjust the trunnion knobs until it’s spot on. Remember: even a tiny misalignment can lead to big problems! Lastly, try running a test cut on scrap wood. If it’s smooth, you’ve nailed it! If not, check your work again. Keep practicing, and soon you’ll be a bandsaw alignment expert!

| Step | Action |

|---|---|

| 1 | Turn off and unplug the bandsaw. |

| 2 | Check and tune blade tension. |

| 3 | Adjust blade guides for proper clearance. |

| 4 | Use a square to check blade alignment. |

| 5 | Run a test cut with scrap wood. |

Preventive Maintenance for Bandsaw Alignment

Key maintenance practices to avoid alignment problems. Frequency of maintenance checks to ensure optimal performance.Keeping your bandsaw in top shape is easier than you think! Regular checks can save you from future headaches. For starters, inspect the blade tension often. Check for wear and tear too. To avoid those pesky alignment issues, schedule maintenance every month. Catching small problems now can prevent bigger ones later. Think of it like brushing your teeth. Miss a few days, and you could end up with a cavity!

| Maintenance Task | Frequency |

|---|---|

| Check blade tension | Monthly |

| Inspect blade for wear | Monthly |

| Clean the saw | Weekly |

| Lubricate moving parts | Every use |

So, treat your bandsaw like a pet! A little love and care go a long way, making projects smoother and more enjoyable.

Troubleshooting FAQs

Frequently asked questions regarding bandsaw alignment troubleshooting. Expert answers and insights into common dilemmas.Many people encounter problems with bandsaw alignment. Here are some common questions and answers that can help. How often should I check the alignment? It’s good to check the alignment before each major project. What if the blade wanders? Make sure the blade is sharp and aligned correctly. Can vibrations cause issues? Yes, vibrations can lead to misalignment. Make sure your bandsaw is stable.

Common Questions

- What’s the first step in troubleshooting? Start by checking the blade tension.

- How do I know if the wheels are aligned? Use a straightedge to compare distances from the blade.

Expert Tips for Enhanced Bandsaw Performance

Tips from professionals on maximizing bandsaw performance through proper alignment. Recommendations for ongoing learning and improvement in band saw use.To boost your bandsaw’s performance, focus on precise alignment. Experts recommend checking the blade tension regularly. A well-tensioned blade cuts straight and smooth. Adjust the guides for proper clearance to ensure the blade moves freely. Here are a few tips:

- Check blade tracking often.

- Keep the saw clean and well-maintained.

- Practice using the bandsaw with different materials.

These simple steps can make a big difference in your cuts!

How can I improve my bandsaw skills?

Practice regularly and seek advice from experienced users.Conclusion

In summary, bandsaw alignment troubleshooting is essential for smooth cutting. Check the blade and guides regularly. Adjust the tension carefully for precision. Remember to inspect your setup often. By practicing these steps, you can improve your cuts and extend your bandsaw’s life. For more tips, explore guides or videos online to enhance your skills!FAQs

Sure! Here Are Five Questions Related To Bandsaw Alignment Troubleshooting:Sure! Here are five questions you might ask when fixing a bandsaw: 1. Why is my bandsaw not cutting straight? 2. How can I tell if the blade is loose? 3. What do I do if the blade wobbles? 4. Why does the blade keep jumping off the wheels? 5. How can I fix the guide blocks? If you have any of these problems, don’t worry! We can figure it out together.

Sure! Please provide the question you’d like me to answer.

What Are The Common Signs That A Bandsaw Is Out Of Alignment?If a bandsaw is out of alignment, you might notice some signs. First, the cuts could be crooked or not straight. Second, you might hear a loud noise while cutting. Third, it could produce a rough edge on the wood. Lastly, the blade may wander off the cutting line, making it hard to follow.

How Can I Determine If The Blade Is Tracking Properly On A Bandsaw Wheel?To check if the blade is tracking properly on a bandsaw wheel, first, turn on the saw and watch the blade. It should stay centered on the wheel, not sliding off to the side. You can also look for any strange noises or shaking. If the blade moves unevenly, you may need to adjust it. Always turn off the saw before making any changes!

What Adjustments Should Be Made If The Bandsaw Blade Is Leaning To One Side During Operation?If the bandsaw blade is leaning to one side, you need to check the tracking. You can adjust the blade on the wheels to make it straight. If it’s still not straight, look at the blade tension. You might need to tighten or loosen it slightly. Always remember to turn off the machine before making these changes!

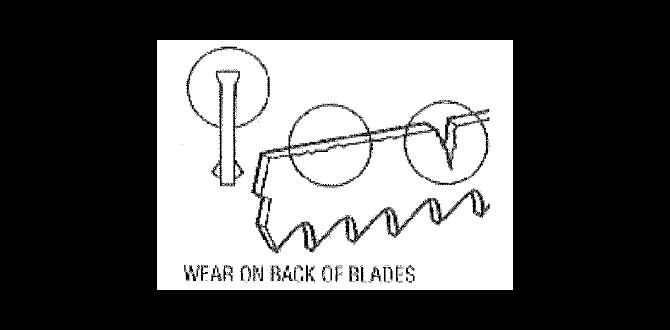

How Can Worn Or Damaged Bandsaw Components Affect Alignment, And What Should I Check For?Worn or damaged parts of a bandsaw can make it harder to keep everything straight. If the blade guides are broken, the blade might not stay in the right place. You should check the blade, the guides, and the wheels for any wear or damage. Make sure everything is tight and looks okay. If something seems off, it can cause problems when cutting.

What Maintenance Practices Can Help Prevent Alignment Issues With A Bandsaw Over Time?To keep a bandsaw working well, you should check the blade often. Make sure it’s tight and straight. Clean the saw regularly to remove dust and debris. Lubricate any moving parts so they work smoothly. Lastly, always follow the manufacturer’s instructions for care.