Quick Summary:

To avoid blow-through with trim, use the right nail gauge, adjust your nailer’s depth setting, ensure a flush fit against the surface, and consider glue for extra hold. Proper technique prevents fasteners from tearing through delicate trim.

Hey there DIYers! Jack Shaffer here, your friendly neighborhood Nailerguy. We’ve all been there, right? You’re carefully installing some beautiful new trim, picturing that perfect finished look, and suddenly – crunch. Your nailer punches straight through, leaving a jagged hole and a bit of frustration. It’s a super common issue, especially for beginners, and it can really mar an otherwise perfect project. But don’t worry, it’s totally fixable and, more importantly, preventable! In this guide, we’re going to break down exactly how to avoid this annoying “blow-through” problem, so you can get that professional-looking finish you’re after. We’ll cover everything from choosing the right tools to perfecting your technique. Let’s get those nails driving true!

Table of Contents

Understanding the Dreaded “Blow-Through”

Blow-through, in the world of trim carpentry, means the nail fastener has essentially torn the material it’s supposed to be holding. Instead of sinking neatly into the wood and staying put, the driven nail rips through the surface, creating a messy, unsightly hole that’s often bigger than the nail head itself. This is particularly common with softer woods, thin trim materials, or when using a nailer that’s set too aggressively.

Think of it like trying to push a sharp needle through a piece of tissue paper versus a sturdy canvas. The tissue paper will tear easily, while the canvas will resist. Trim wood, especially delicate profiles or engineered materials, can act like that tissue paper if you’re not careful. The force from the nail gun, while necessary to seat the nail properly, can be too much if not managed correctly for the specific material.

The frustration comes from the fact that it often happens at the worst possible moment – when you’re nearing the end of a piece, or right where it’s most visible. But the good news is, once you understand why it happens, you’re halfway to solving it. We’ll dive into the specific culprits and, more importantly, the easy fixes.

The Key Factors: What Causes Blow-Through?

Several factors contribute to blow-through. Understanding each one is crucial for prevention. Let’s break them down:

1. Nail Gauge and Length

The “gauge” of a nail refers to its thickness. Thinner nails (like 18-gauge or 16-gauge) are generally used for trim because they leave a smaller hole and are less likely to split the wood. Thicker nails (lower gauge numbers) are stronger and harder to drive but can cause more damage.

Similarly, using a nail that’s too long for the trim thickness can cause it to exit the back or sides prematurely, especially if the trim is thin and being nailed into a harder substrate. Imagine nailing a half-inch thick piece of trim into drywall – a 2-inch nail will have plenty of power to go right through the trim and whatever is behind it!

2. Air Pressure Settings

Your air compressor is set to a specific pressure (measured in PSI – pounds per square inch). Too much air pressure delivers too much force with each nail. This is probably the most common culprit for beginners. That powerful blast intended to sink the nail deep can easily overpower weaker materials, leading to blow-through.

3. Depth Adjustment Setting

Most modern nail guns have a depth adjustment mechanism. This allows you to control how deep the nail is driven. If this setting is too high (meaning it’s set to drive the nail deeply), even with the correct air pressure, the gun will attempt to sink the nail too far, increasing the risk of blow-through.

Think of it as a trigger sensitivity for depth. If it’s set too sensitive, it goes too deep. If it’s not sensitive enough, the nail will stick out.

4. Material Type and Quality

As mentioned, softer woods like pine, poplar, or MDF (Medium Density Fiberboard) are more prone to blow-through than hardwoods like oak or maple. Engineered wood products, especially those with a thin veneer, can also be tricky. The way the material is manufactured can also play a role; sometimes, there are internal voids or weaker spots that a nail can easily punch through.

5. Angle of Approach

Nailing straight on is usually best. If you drive the nail at an angle, especially through a corner or edge of a trim piece, you increase the chance of the nail exiting the wood at an unwanted spot or tearing the fibers on the way out.

6. Substrate and Support

What are you nailing into? Nailing trim directly into drywall without hitting a stud can lead to blow-through because the drywall itself offers very little resistance. The nail can easily push through the thin paper facing and the gypsum core. While it might hold the trim momentarily, it’s not a secure fastening.

Conversely, nailing into solid wood studs or framing lumber provides excellent backing. However, if your trim is very thin and you’re driving a thick nail with significant force into a very hard underlying wood stud, you can still cause internal fracture and blow-through. It’s about finding that balance.

Essential Tools and Materials for Blow-Through Free Trim

Before you even pick up your nailer, ensure you have the right gear. Having the correct tools makes a huge difference in achieving a professional result.

1. The Right Nailer

For most interior trim work like baseboards, crown molding, and window/door casing, a finish nailer is your go-to. These typically accept 16-gauge or 15-gauge nails.

- 16-Gauge Finish Nailer: Excellent for delicate trim, smaller profiles, and when you want minimal damage. They use thinner nails that are less likely to split wood.

- 15-Gauge Finish Nailer (Finner Nailer): Uses a slightly thicker nail than a 16-gauge. Offers a bit more holding power but has a slightly larger hole. Good for heavier trim or when you need that extra grip.

- 18-Gauge Brad Nailer: Uses very thin nails. Ideal for very delicate trim, craft projects, or attaching thin moldings. Less holding power, so not ideal for structural trim like baseboards unless it’s very light.

2. Appropriate Nails

Always match your nails to your nailer and your trim material.

- Gauge: As discussed, 16-gauge is a fantastic all-rounder for trim.

- Length: This is critical. For trim, you typically want a nail that’s long enough to go through the trim and penetrate at least 1/2-inch to 3/4-inch into the solid backing material (like wood studs). Common lengths for trim are 1-1/2″ to 2-1/2″. Never use a nail so long that it will absolutely blast through the reverse side.

- Type: Galvanized or stainless steel for exterior trim or areas prone to moisture. Interior trim can use regular steel nails.

3. Air Compressor and Hose

Ensure your air compressor can provide consistent pressure to your nailer. It needs to be powerful enough to drive the nails effectively but also controllable.

4. Safety Gear

This is non-negotiable and crucial for any tool use:

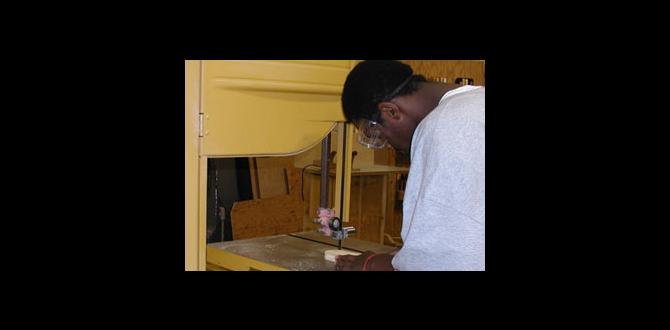

- Safety Glasses: Protect your eyes from flying debris or nail fragments. Always wear them!

- Hearing Protection: Nail guns can be loud. Earplugs or muffs are recommended for extended use.

5. Wood Glue (Optional but Recommended)

A good quality wood glue can significantly enhance holding power and reduce reliance solely on the nail. It’s especially useful for joints or when using lighter trim.

6. Stud Finder

To locate wall studs, ensuring you have solid backing for your trim. You can find reliable stud finders from brands like Zircon or Franklin Sensors. For those who prefer digital, consider options like the Franklin Sensors which can detect multiple stud locations at once.

Step-by-Step Guide: How to Prevent Blow-Through

Now that we’ve covered the ‘why’ and ‘what you need,’ let’s get to the ‘how.’ Follow these steps diligently, and you’ll see a dramatic improvement in your trim installation results.

Step 1: Read Your Nailer’s Manual

Seriously! Every nailer is a little different. Your manual will explain how to adjust depth, check air pressure recommendations, and offer specific maintenance tips. Familiarizing yourself with your tool is the first step to mastering it. You can often find digital copies of manuals online by searching for your nailer’s model number.

Step 2: Perform a Test Drive

This is the MOST important step and often skipped by beginners. Before you nail a single piece of trim, grab a scrap piece of the exact same material you’ll be using. Set up your nailer with a starting air pressure (around 80-90 PSI is a good general starting point, but check your tool’s manual for specifics). Then, try firing a few nails into the scrap wood.

- Observe: Are the nails sinking flush? Are they poking out? Are they tearing the wood (blow-through)?

- Adjust:

- Nail sticking out: Increase air pressure slightly OR increase the depth setting.

- Nail sinking too deep / Blow-through: Decrease air pressure OR decrease the depth setting.

You are looking for the sweet spot where the nail head is just slightly below or perfectly flush with the surface of the trim, without any tearing or splintering.

Step 3: Set the Correct Air Pressure

Based on your test drive, find that optimal PSI. It’s better to err on the side of too little air pressure and have to increase it gradually than to start too high and blow through your first piece. A good PSI range for most trim work with a 16-gauge nailer is typically between 70-110 PSI, but this can vary significantly based on the nailer, hose length, and compressor. Always check your tool manufacturer’s recommendations.

For reference, here’s a general guideline, but remember that testing is key:

| Nailer Type | Typical PSI Range (for optimal seating without blow-through) | Material Consideration |

|---|---|---|

| 18-Gauge Brad Nailer | 60-90 PSI | Best for very delicate trim; lower pressure is safer. |

| 16-Gauge Finish Nailer | 70-110 PSI | Versatile for most trim; adjust for wood hardness. |

| 15-Gauge Finner Nailer | 80-120 PSI | Slightly higher pressure may be needed for thicker nails. |

Note: Always test and adjust for your specific tool and material.

Step 4: Dial in the Depth Adjustment

Once your air pressure is dialed in using your scrap wood, use the nailer’s depth adjustment wheel or lever. This is usually a dial near the nose of the gun that you can turn to make the nail sink deeper or shallower. You want the nail to be flush with the surface or just barely countersunk (slightly below the surface), without blowing through.

If your nailer doesn’t have a depth adjustment, you’ll have to rely solely on air pressure. In that case, finding the exact right PSI becomes even more critical.

Step 5: Ensure a Flush Fit Against the Trim

This sounds simple, but it’s critical. When you place the nose of the nailer against the trim, make sure it’s sitting perfectly flat and flush. Any angle can cause the nail to drive unevenly or exit the wood prematurely. Press the nailer firmly against the trim before and during firing.

Don’t just “hover” the nailer; give it a gentle, firm push into the material. This ensures the nose piece is seated properly and helps prevent kickback or the nail skittering.

Step 6: Nail into Studs or Solid Backing

Always aim to drive your trim nails into solid wood framing (studs or cripples). Use a stud finder to locate them. If you can’t hit a stud, consider using construction adhesive behind the trim for extra hold, but be aware that this alone won’t prevent blow-through if the nail is driven too hard.

You can learn more about finding studs and proper framing techniques from resources like Fine Homebuilding, a reputable source for building professionals and serious DIYers.

Step 7: Use Wood Glue for Extra Hold

For critical joints or delicate trim, apply a thin bead of wood glue to the back of the trim piece before pressing it into place. Then, nail it. The glue adds significant holding power and can help minimize the risk of blow-through by adding structural integrity. Wipe away any excess glue immediately with a damp cloth.

Step 8: Be Mindful of Corners and Edges

When nailing near the edge or corner of a piece of trim, the material is naturally weaker. You may need to slightly reduce your air pressure or depth setting for these areas, or even pre-drill a small pilot hole (though this is often not practical for fast trim work). Driving nails parallel to the edge and away from corners can also help.

Step 9: Fire Smoothly, Don’t Slam

Avoid “slamming” the nailer into the wood. A smooth, controlled press and trigger pull is more effective. Let the tool do the work.

Step 10: Check Your Work As You Go

After each nail, take a quick look. Is it set correctly? Any signs of damage? It’s much easier to fix a single bad nail or adjust your settings immediately than to discover multiple problems at the end of a long run.

Troubleshooting Common Blow-Through Scenarios

Even with the best intentions, you might run into sticky situations. Here’s how to tackle them:

Scenario 1: Thin Veneer or MDF Trim

Problem: These materials are very prone to tearing.

Solution:

- Use a 16-gauge or 18-gauge nailer for the thinnest nails.

- Significantly reduce air pressure (start as low as 60-70 PSI and increase slowly).

- Ensure the depth adjustment is set to its shallowest setting that still drives the nail flush or just under.

- Consider the glue-and-nail method for added support.

- Nail only into studs, or use construction adhesive.

Scenario 2: Nailing into a Very Hard Wood Stud

Problem: The nail drives fine into the trim but then encounters extremely hard wood, causing it to splinter or blow out the face of the trim.

Solution:

- Slight. reduce the air pressure.

- Ensure the depth setting isn’t too aggressive.

- If using very long nails, consider a slightly shorter length that still provides adequate penetration into the stud (aim for at least 1/2 inch).

- Sometimes, a nailer with sequential trip (one nail at a time) can offer better control than a contact trip (fire as you bump it).

Scenario 3: Pre-finished Trim

Problem: You don’t want to damage the finish.

Solution:

- Use the lowest possible air pressure and depth setting that still seats the nail correctly.

- Consider placing a thin piece of cardboard or paint-stirrer between the nailer’s safety contact and the trim to distribute the pressure.

- Use a nailer with a no-mar nose tip.

- If blow-through occurs, touch up the finish on the nail head and surrounding area. Small, slightly countersunk nails are easier to touch up.

Scenario 4: Multiple Nails Blown Through in One Area

Problem: You’ve tried multiple times, and it keeps happening.

Solution:

- Stop! Take a break.

- Re-evaluate your air pressure and depth settings on scrap wood.

- Check if the trim material itself is compromised in that area